Honey Whiskey Moonshine Recipe: Expertly Craft It In 5 Steps

Key Takeaways

- Honey whiskey moonshine combines the sweet complexity of honey with the bold character of traditional whiskey for a uniquely smooth spirit.

- Using specialty honey varieties like wildflower or buckwheat can dramatically transform your whiskey’s flavor profile.

- While commercial distillation requires proper licensing, this guide shows the authentic process used by professional distillers.

- The quality of your moonshine depends heavily on precise temperature control during fermentation and careful cuts during distillation.

- Aging with toasted oak chips can transform raw honey whiskey into a refined spirit with remarkable depth in just 2-3 weeks.

Crafting honey whiskey moonshine is an art that blends time-honored distilling traditions with the natural sweetness of one of nature’s most perfect foods. When done right, the result is a smooth, complex spirit that carries subtle floral notes and a warmth that can’t be matched by commercial alternatives. Clawhammer Supply, specialists in home distilling equipment and education, continues to share this traditional craft with enthusiasts who appreciate the difference that comes from small-batch, carefully crafted spirits.

The journey to creating exceptional honey whiskey starts with understanding what makes this particular style so special. Unlike mass-produced honey-flavored whiskeys that often rely on artificial additives, authentic honey whiskey moonshine derives its character from real honey integrated throughout the production process. This marriage of honey’s complex sugars with traditional distillation techniques creates something truly remarkable.

The Sweet Allure of Honey Whiskey Moonshine

“Honey Vanilla Moonshine Whiskey – Doc …” from www.doccollins.nl and used with no modifications.

Honey whiskey moonshine stands apart in the world of craft spirits with its distinctive golden hue and complex flavor profile that evolves with each sip. The natural enzymes in honey transform during fermentation, creating depth that simple sugar-based spirits can’t achieve. This ancestral beverage connects us to generations of distillers who discovered that honey’s complex sugars ferment into remarkably smooth alcohol with unique character.

What makes honey whiskey truly special is the interplay between the base whiskey character and the honey’s terroir – the environmental factors that influence its taste. Just as wines reflect their vineyard’s unique conditions, honey carries the essence of specific flowering plants, soils, and climate conditions. When properly incorporated into whiskey, these subtle notes create a spirit with extraordinary complexity that can’t be replicated through artificial flavorings.

What Makes Honey Whiskey Moonshine Special?

“Ole Smoky Honey Charred Moonshine – Hi …” from www.hiiqliquor.co.nz and used with no modifications.

The marriage of honey and whiskey creates a spirit that balances sweetness with depth, offering complexity that few other homemade spirits can match. Traditional moonshine can sometimes carry a harsh edge, but honey’s natural sugars and enzymes help create a smoother mouthfeel and rounded finish. The result is a beverage that appeals to both whiskey connoisseurs and those who typically find straight spirits too intense.

The Unique Flavor Profile of Honey-Infused Whiskey

Honey whiskey moonshine offers a tasting experience that evolves from the moment it touches your lips. The initial sweetness opens up to reveal layers of flavor – floral notes, subtle fruit undertones, and a warm finish that lingers pleasantly. What makes this spirit remarkable is how the honey doesn’t merely sweeten but fundamentally transforms the whiskey’s character. Depending on your chosen honey variety, you might detect hints of apple blossom, citrus, wildflowers, or even rich buckwheat notes that complement the whiskey’s natural grain profile.

How It Differs From Commercial Honey Whiskeys

Commercial honey whiskeys typically rely on honey flavoring added after distillation, often with artificial sweeteners or flavor enhancers. By contrast, authentic honey whiskey moonshine incorporates real honey during the fermentation process or through careful post-distillation infusion. This fundamental difference creates a spirit with genuine complexity rather than simply adding sweetness as an afterthought. The result is a more authentic product where the honey becomes an integral part of the spirit’s character rather than merely a flavoring agent.

Essential Ingredients for Authentic Honey Whiskey

“Homemade Honey Whiskey (Better than …” from feastandwest.com and used with no modifications.

Creating exceptional honey whiskey moonshine begins with selecting quality ingredients that will form the foundation of your spirit. While the process might seem straightforward, each component dramatically influences your final product. Professional distillers understand that the quality of what goes into the still directly determines what comes out, with no shortcuts or workarounds possible.

At minimum, you’ll need a gallon of quality honey, 5 gallons of filtered water, appropriate distiller’s yeast, and yeast nutrients to ensure proper fermentation. Many craft distillers also incorporate traditional whiskey grains like corn, barley, or rye to add complexity, though pure honey spirits can be exquisite in their simplicity.

Choosing the Right Honey Variety

The honey you select serves as the soul of your whiskey, contributing not just sweetness but complex aromatics and flavor notes that will define your final product. Wildflower honey offers balanced floral notes that complement traditional whiskey profiles, while buckwheat honey provides a robust, molasses-like character for bolder spirits. Orange blossom honey contributes subtle citrus undertones that brighten the final product. Specialty varieties like meadowfoam or sourwood can create truly distinctive spirits with unique flavor profiles impossible to achieve otherwise. For more inspiration, explore this traditional corn-based moonshine recipe.

Honey Varieties and Their Whiskey Characteristics

Wildflower: Balanced, floral, versatile foundation

Buckwheat: Dark, robust, almost malty character

Orange Blossom: Bright citrus notes, subtle sweetness

Clover: Mild, clean sweetness for lighter spirits

Tupelo: Distinctive vanilla notes, rarely crystallizes

The price difference between generic store-bought honey and premium varieties can be substantial, but the impact on your final product justifies the investment. While basic clover honey might cost $20-30 per gallon, specialty varieties can fetch $75 or more. Remember that these premium honeys carry unique flavor compounds that will transfer directly to your whiskey, creating a truly artisanal spirit impossible to replicate with generic alternatives.

Selecting Quality Water for Your Mash

Water makes up the majority of your mash and directly impacts both fermentation efficiency and flavor. Professional distillers often use filtered spring water to avoid unwanted minerals or chemical treatments that can influence fermentation. If using tap water, consider letting it sit overnight to allow chlorine to evaporate, or invest in a carbon filter system to remove impurities. The ideal water should be clean, neutral in pH (between 6.5-7.5), and free from strong odors or flavors that could transfer to your final spirit.

Yeast Selection for Optimal Fermentation

The yeast strain you choose will significantly influence both fermentation efficiency and flavor development in your honey whiskey. Super Start distiller’s yeast or similar high-alcohol tolerant strains are ideal as they can handle the high sugar content from honey while producing clean flavors. Wine yeasts like D47 or 71B offer interesting flavor development but may not reach the same alcohol levels as dedicated distilling yeasts. Regardless of strain, always use fresh yeast and follow proper rehydration techniques to ensure vigorous fermentation that minimizes off-flavors from stressed yeast cells. For more insights into moonshine and distilling processes, explore the main parts of a still.

Additional Flavor Enhancers (Optional)

While honey provides excellent flavor on its own, many distillers enhance their spirits with complementary ingredients. Traditional whiskey grains like flaked corn (9 pounds) and malted barley (2 pounds) can create a more complex base that highlights the honey’s sweetness. Some artisanal producers add subtle spices like cinnamon, vanilla bean, or orange peel during aging to complement honey’s natural character. For a truly distinctive spirit, consider adding small amounts of complementary fruits that pair well with your chosen honey variety – apples work wonderfully with wildflower honey, while berries can enhance darker buckwheat honey profiles.

Equipment You’ll Need Before Starting

“copper moonshine still distiller” from www.napafermentation.com and used with no modifications.

Creating quality honey whiskey moonshine requires proper equipment that ensures both safety and quality results. While professional distillers invest in commercial-grade systems, even small-batch production needs certain essential components. The right tools not only make the process easier but significantly impact the character and purity of your final spirit.

At minimum, you’ll need a fermentation vessel, airlock system, heat source, mash cooker, proper distillation equipment, and appropriate storage containers for the finished product. Temperature monitoring tools throughout the process are essential for consistent results. Remember that proper sanitation equipment is equally important – even the best ingredients can yield poor results if contamination occurs.

Distillation Setup Requirements

A proper distillation setup is the cornerstone of quality spirit production. Professional distillers use copper stills due to copper’s ability to remove sulfur compounds during distillation, resulting in cleaner spirits. The still should include a proper column, condenser with adequate cooling capacity, and accurate temperature monitoring. Proper collection vessels for separating “cuts” during distillation are essential for quality control. Safety features including proper ventilation and heat source controls should never be overlooked, as alcohol vapors are highly flammable and require appropriate safety measures.

Fermentation Vessels and Airlocks

Fermentation vessels should be food-grade plastic or glass with sufficient capacity to handle the mash volume plus headspace for foaming during active fermentation. A 7-8 gallon fermenter is typically adequate for a 5-gallon mash recipe. The vessel must be equipped with an effective airlock that permits carbon dioxide release while preventing oxygen and contaminants from entering. Many distillers prefer wide-mouth fermenters that allow easy access for stirring and ingredient additions. Remember that light exposure can negatively impact fermentation, so opaque or amber containers offer better protection for developing optimal flavors.

Temperature Control Tools

Consistent temperature control dramatically impacts fermentation quality and efficiency when creating honey whiskey. Professional distillers maintain temperatures between 70-75°F (21-24°C) for optimal yeast performance with most distiller’s yeasts. A reliable adhesive thermometer strip on your fermenter provides basic monitoring, while digital temperature controllers offer more precise regulation. For serious producers, fermentation heating belts or cooling systems may be necessary depending on your ambient environment. Remember that temperature fluctuations stress yeast, potentially creating off-flavors, so stability is more important than achieving a specific ideal temperature.

Monitoring tools for the distillation process are equally important, as precise temperature readings help identify when to make proper cuts between foreshots, heads, hearts and tails during the run. A quality digital thermometer with a probe that can be inserted into the column will provide the accuracy needed for consistent results batch after batch. For more information on the distillation process, check out this moonshine guide.

5 Steps to Craft Perfect Honey Whiskey Moonshine

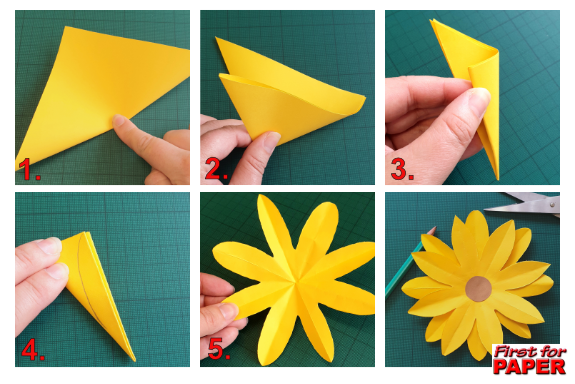

“Simple Paper Craft Projects You Can Try …” from www.firstforpaper.co.uk and used with no modifications.

Creating exceptional honey whiskey moonshine follows a methodical process refined by generations of distillers. While seemingly straightforward, each step requires attention to detail and understanding of the chemical and biological processes at work. The transformation from raw ingredients to refined spirit involves precise timing, temperature control, and knowing when to intervene – and when to let nature take its course.

The five key stages – mash preparation, fermentation, first distillation, spirit run, and final infusion/aging – each contribute uniquely to your whiskey’s character. Master distillers know that rushing any stage compromises quality, while patience yields remarkable results that can’t be achieved through shortcuts. Let’s break down each essential step to craft a honey whiskey moonshine you’ll be proud to share.

1. Prepare Your Honey Mash

Creating your honey mash begins with heating water to approximately 120°F (49°C) – hot enough to dissolve honey efficiently without destroying its delicate aromatic compounds. Add your honey to the heated water gradually, stirring continuously to ensure complete dissolution without scorching. This careful process preserves the honey’s distinctive flavor notes while creating a fermentable sugar solution. For enhanced complexity, some distillers incorporate traditional whiskey grains like 9 pounds of flaked corn and 2 pounds of malted barley alongside the honey.

Once your honey has completely dissolved, it’s essential to cool the mixture to 80°F (27°C) before adding yeast. Excessive heat will kill yeast cells and prevent proper fermentation. Professional distillers use wort chillers or ice baths to accelerate cooling while minimizing exposure to potential contaminants. Once at the proper temperature, add yeast nutrient according to package directions – honey lacks some nutrients yeast requires for optimal performance, making this addition crucial for complete fermentation.

The final step in mash preparation involves pitching your selected yeast strain. Properly rehydrate dried yeast according to manufacturer instructions rather than adding it directly to the mash. This brief extra step dramatically improves yeast viability and fermentation performance. Once added, stir the mash thoroughly to incorporate oxygen, which yeast cells need for their initial reproduction phase before fermentation begins in earnest.

2. Ferment the Mash Properly

Transfer your prepared honey mash to a sanitized fermentation vessel, leaving at least 20% headspace to accommodate the foam that will form during active fermentation. Seal the vessel with an airlock filled with sanitizing solution to prevent contamination while allowing carbon dioxide to escape. Place the fermenter in a location with stable temperature between 70-75°F (21-24°C) – fluctuations stress yeast and create off-flavors, while temperatures that are too high produce fusel alcohols that carry harsh flavors and intensify hangovers.

Honey fermentation typically takes longer than grain or sugar mashes due to its complex sugar profile – expect 10-14 days for complete fermentation rather than the 5-7 days common with simpler sugar sources. Monitor fermentation progress by watching airlock activity and taking hydrometer readings every few days. Active fermentation will show regular bubbling through the airlock, which gradually slows as sugars are consumed. Patience during this stage is essential – rushing to distillation before fermentation completes results in lower yields and potential off-flavors. If you’re interested in learning more about the traditional corn-based moonshine recipe, it can provide a different perspective on fermentation times and methods.

The fermentation is complete when hydrometer readings stabilize at the same value for three consecutive days, typically reaching a final gravity between 0.990 and 1.000 depending on your initial sugar content and yeast strain. At this point, your mash contains approximately 10-14% alcohol by volume, along with all the flavor compounds that will define your finished whiskey. Allow the finished mash to settle for 24-48 hours before proceeding to distillation to let yeast and particulates fall to the bottom, resulting in a cleaner distillation run.

3. Run Your First Distillation

The first distillation, often called the “stripping run,” concentrates alcohol and flavors from your fermented honey mash. Transfer your settled mash to the still, being careful to leave behind as much yeast sediment as possible to prevent scorching and off-flavors. Fill your still to no more than 80% capacity to prevent boilover and ensure proper vapor flow. During this initial run, maintain a steady heat source to achieve a slow, controlled temperature increase rather than rapid boiling, which can cause flavor compounds to carry over prematurely.

As your wash heats, it will eventually reach approximately 172°F (78°C) when alcohol begins to vaporize. Professional distillers collect everything that comes off this first run without making cuts, as the purpose is simply to concentrate the alcohol for a more refined second distillation. The collected liquid, known as “low wines,” typically contains between 25-45% alcohol by volume. This run efficiently processes large volumes of wash but produces a rough spirit that requires further refinement.

Continue the stripping run until the distillate coming off measures approximately 20% alcohol by volume (about 40 proof) or the still temperature reaches around 205°F (96°C). Collecting distillate beyond this point yields diminishing returns of alcohol while extracting undesirable compounds that can affect flavor. This first distillation concentrates the approximately 6 gallons of 10-12% wash into roughly 1-1.5 gallons of low wines at 30-40% alcohol, preparing it for the critical spirit run where the real artistry happens. For more on the process, learn about the onion head on a still.

4. Perform the Spirit Run

The spirit run transforms your low wines into refined honey whiskey through careful separation of different alcohols and flavor compounds. Begin by diluting your low wines to approximately 40% ABV (80 proof) with filtered water, which improves separation of compounds during distillation. Load this diluted solution into a clean still and heat more gently than during the stripping run – patience here significantly impacts quality. As the still approaches 172°F (78°C), prepare separate containers for foreshots, heads, hearts, and tails collections.

The first 150ml per 5 gallons of wash are foreshots containing methanol and other toxic compounds that must be discarded. Following foreshots come the heads, approximately the next 15-20% of your expected total yield, containing harsh alcohols and compounds with low boiling points. While heads aren’t dangerous like foreshots, they contribute unpleasant flavors and aromas, so most distillers collect them separately for redistillation in future batches. Making these initial cuts correctly is critical for both safety and quality.

- Foreshots (discard): First 150ml per 5 gallons, contains methanol

- Heads (set aside): Sharp, solvent-like aroma, approximately 15-20% of yield

- Hearts (keep): Clean, sweet aroma with honey notes, 60-70% of yield

- Tails (optional): Diminishing honey notes, increasing cereal/water flavors

The hearts fraction contains the pure, clean spirit that will become your honey whiskey. This middle portion carries the honey’s floral notes alongside the clean ethanol that serves as their vehicle. Professional distillers make cuts based primarily on smell and taste rather than temperature or ABV alone – the transition from heads to hearts is unmistakable as the sharp, solvent-like aroma transforms into a clean, sweet scent. Collect hearts until you notice the aroma fading and developing a more watery character, signaling the beginning of the tails fraction. For more details on the distillation process, check out this guide on making moonshine.

5. Infuse and Age with Honey

The final transformation of your distilled spirit into honey whiskey involves artful post-distillation techniques. For a traditional approach, dilute your hearts fraction to approximately 50-60% ABV (100-120 proof) using filtered water. This dilution makes the spirit more receptive to taking on flavors during aging while remaining strong enough for proper preservation. Some distillers add a small amount of fresh honey at this stage – typically 2-4 tablespoons per quart of spirit – to enhance the honey character without making the whiskey overly sweet.

For proper aging, add 2-3 tablespoons of toasted American oak chips per quart of spirit. Light or medium toast chips contribute vanilla and caramel notes that complement honey beautifully without overwhelming its delicate flavors. Store your aging spirit in glass containers away from direct light, ideally at a consistent room temperature. Unlike commercial whiskey that may age for years, honey whiskey moonshine typically reaches optimal flavor in just 2-3 weeks with oak chips, as the increased surface area accelerates extraction compared to traditional barrels.

After the initial aging period, taste your honey whiskey to assess its development. If the oak influence is appropriate but you want more honey character, consider adding a final honey infusion by dissolving a small amount of honey in a portion of your whiskey, then blending it back into the main batch. This technique allows precise control over sweetness and honey intensity. Once you’ve achieved your desired flavor profile, filter the spirit through a coffee filter to remove oak particles before transferring to bottles for storage or serving. For creative packaging ideas, you can explore aged moonshine packaging ideas.

Troubleshooting Common Issues

“49,800+ Common Problem Stock Photos …” from www.istockphoto.com and used with no modifications.

Even experienced distillers occasionally encounter challenges when crafting honey whiskey. Recognizing and addressing these issues promptly ensures consistent, high-quality results. Most problems originate during fermentation or distillation but can be corrected with proper understanding of the underlying causes.

Slow or Stuck Fermentation Fixes

When fermentation slows or stops prematurely, first check fermentation temperature – honey mashes perform best between 70-75°F (21-24°C). Temperatures below this range cause yeast to become sluggish, while higher temperatures may stress yeast into dormancy. If temperature is appropriate, consider insufficient yeast nutrients as honey lacks many compounds yeast needs for healthy reproduction and metabolism. Add a supplemental dose of yeast nutrient and gently stir the mash to redistribute active yeast cells.

For persistently stuck fermentations, creating a “yeast starter” often solves the problem. Prepare a small amount of diluted honey water (1 part honey to 4 parts water), add a fresh packet of yeast, and allow it to become vigorously active before adding this mixture to your main fermentation vessel. This introduces a healthy yeast population that can often overcome whatever caused the original stall. As a preventative measure for future batches, consider using staggered honey additions rather than fermenting all honey at once, which reduces osmotic pressure on yeast cells. For those interested in the history of moonshine, you might find the secret history of corn moonshine intriguing.

Dealing with Off Flavors

Sulfur aromas (rotten egg smell) occasionally develop during fermentation of honey mashes. This results from yeast stress or insufficient nutrient levels and typically dissipates during distillation, especially when using copper stills. For persistent sulfur notes, adding a clean copper scrubber to your spirit during aging can help remove these compounds through chemical reaction with the copper surface.

If your finished spirit has a harsh, solvent-like character, you’ve likely included too much of the “heads” fraction during your spirit run. This can be remedied by performing another careful distillation with more conservative cuts, or by extended aging with oak, which helps transform some of these harsher compounds. For a medicinal or plastic-like taste, bacterial contamination may have occurred during fermentation – unfortunately, these flavors typically can’t be removed, emphasizing the importance of proper sanitation throughout the process.

Adjusting Sweetness Levels

Finding the perfect balance of honey sweetness can be challenging, as distillation removes most of honey’s sugars while retaining some flavor compounds. If your finished whiskey lacks sufficient honey character, create a honey simple syrup by dissolving one part honey in one part hot water, then cooling. Add this mixture to your aged spirit in small increments until achieving desired sweetness, keeping notes on proportions for future batches. Remember that honey flavors will integrate more fully after a few days of bottle aging.

Conversely, if your whiskey tastes overly sweet from too much honey addition, dilution with unflavored spirits from the same batch can help balance the profile. Alternatively, additional oak aging can counter sweetness with tannins and woody notes that provide complexity and dryness. When making adjustments, always work in small increments and allow time for flavors to marry before making additional changes – patience here prevents over-correction that can ruin an otherwise promising batch.

Aging and Storing Your Honey Whiskey

“Oak Aging Barrel for Whiskey …” from www.amazon.com and used with no modifications.

Proper aging and storage transforms raw honey whiskey into a refined spirit with remarkable depth. While commercial distilleries age whiskey for years in full-size barrels, small-batch producers can achieve excellent results in much less time using alternative aging techniques. The key is understanding how different variables affect flavor development and applying this knowledge to create a balanced final product. For more inspiration, consider exploring aged moonshine packaging ideas to enhance your presentation.

Oak Aging Techniques

American white oak remains the gold standard for whiskey aging, contributing vanilla, caramel, and subtle spice notes that beautifully complement honey’s floral sweetness. Rather than traditional barrels, many small-batch distillers use oak chips, cubes, or spirals that provide significantly more surface area contact with the spirit. Medium toast oak generally works best with honey whiskey, offering sweetness without overwhelming smokiness that might mask delicate honey notes. For a standard batch, use approximately 2-3 tablespoons of oak chips per quart of spirit, tasting weekly until reaching desired oak influence – typically 2-3 weeks for chips versus years for traditional barrel aging.

Best Storage Conditions

Proper storage conditions significantly impact how your honey whiskey develops over time. Glass containers are ideal, as they’re non-reactive and won’t impart additional flavors. Amber glass offers protection from light that can degrade delicate flavor compounds. Store bottles upright in a cool, dark location with minimal temperature fluctuations – excessive heat accelerates aging while potentially creating harsh flavors, while cold temperatures can cause some compounds to precipitate out of solution.

Maintain consistent temperature between 60-70°F (15-21°C) for optimal aging. While commercial operations use climate-controlled warehouses, a basement or interior closet often provides suitable conditions for home storage. Humidity doesn’t significantly affect sealed bottles but becomes important if using traditional barrel aging where evaporation occurs through wood pores.

Proper bottle filling also impacts long-term storage quality. Minimize headspace in bottles to limit oxidation, which can flatten flavors over time. For spirits you plan to store longer than a few months, consider using smaller bottles that can be filled completely rather than keeping partially-filled larger bottles. For more tips on packaging, explore these aged moonshine packaging ideas.

Aging Container Comparison

Oak Chips: Fast extraction (2-3 weeks), high surface contact, easy to control

Oak Spirals: Medium extraction (1-2 months), moderate oak influence, good complexity

Small Barrels: Slower extraction (3-6 months), traditional profile, requires monitoring

Glass + Oak: Most precise control, allows for sampling without disrupting process

While aging experiments can yield wonderful results, always maintain a control sample of your original distillate for comparison. This reference point helps you evaluate how aging changes your spirit and prevents over-oaking that can mask the honey character you worked so hard to develop. Some distillers maintain detailed tasting notes throughout the aging process, creating a valuable reference for future batches.

How Aging Changes Your Final Product

The transformation that occurs during aging involves complex chemical interactions between the spirit, oak compounds, and oxygen. Fresh off the still, honey whiskey often exhibits sharp edges and disjointed flavor notes despite having good honey character. Over time, harsh alcohols mellow as they form esters with acids from the wood, creating fruity and floral notes that enhance honey’s natural profile. Lignins and hemicellulose from oak break down into vanillin and other compounds that add depth and complexity while softening ethanol’s natural bite.

Enjoying Your Homemade Honey Whiskey Moonshine

“Hot Toddy with Bourbon and Honey – Live …” from livelifelovefood.com and used with no modifications.

Properly crafted honey whiskey moonshine deserves thoughtful presentation to fully appreciate its complex character. Serve at room temperature in a proper whiskey glass with a narrow opening that concentrates aromas. While many enthusiasts enjoy it neat to experience the full honey-oak interplay, a single large ice cube can open up different flavor dimensions as the spirit gradually cools and dilutes. For special occasions, try warming the glass slightly in your hands before sipping to enhance the aromatic honey notes that might otherwise remain subtle.

Beyond straight sipping, honey whiskey moonshine shines in craft cocktails that highlight its unique character. It makes an exceptional Old Fashioned with just a sugar cube, bitters, and orange peel – the honey notes complement the citrus brilliantly. For summer entertaining, mix with fresh lemonade and a sprig of thyme for a sophisticated yet approachable cocktail. Whatever your preferred serving method, take time to appreciate the craftsmanship that transforms simple ingredients into this complex spirit that connects us to centuries of distilling tradition.

Frequently Asked Questions

As you embark on your honey whiskey journey, you’ll likely have questions about the process and potential challenges. These common questions address the concerns most frequently raised by both beginners and experienced distillers exploring honey-based spirits for the first time.

Understanding these fundamentals will help you create exceptional honey whiskey while avoiding common pitfalls that can affect quality or safety. Remember that distilling is both science and art – mastering the technical aspects provides the foundation, but developing your personal style makes each batch uniquely yours.

Is making honey whiskey moonshine legal?

In the United States, distilling spirits at home without proper federal permits remains illegal regardless of whether it’s for personal consumption or sale. The Alcohol and Tobacco Tax and Trade Bureau (TTB) requires permits, bonding, and strict compliance with regulations for any alcohol distillation. However, many enthusiasts legally research traditional techniques and recipes while using professional distilling services or attending workshops at licensed facilities like Clawhammer Supply to experience the craft firsthand under proper supervision. Always check local and federal laws before attempting any aspect of distillation to ensure you remain in compliance with all regulations.

How long does honey whiskey moonshine need to age?

Unlike traditional whiskeys that benefit from years of barrel aging, honey whiskey moonshine typically reaches its peak much faster due to the delicate flavor compounds involved. When using oak chips, two to three weeks often achieves optimal flavor balance between honey character, oak influence, and alcohol integration. The higher surface-to-volume ratio of chips accelerates extraction compared to traditional barrels.

Extended aging beyond a month can actually diminish the distinctive honey notes that make this spirit special, as stronger wood compounds gradually overpower the more delicate floral aspects. For best results, taste your spirit weekly during aging and bottle once you’ve achieved the desired balance. Some distillers reserve a portion without oak to blend back later, which can help restore honey character if oak influence becomes too dominant.

Can I use any type of honey for this recipe?

While any honey will ferment successfully, the variety you choose significantly impacts your whiskey’s final character. Single-source honeys like orange blossom, tupelo, or buckwheat create distinctive spirits with unique flavor profiles that reflect their floral origins. Wildflower honey offers excellent complexity with balanced flavor that complements traditional whiskey notes. Local honeys often contain regional pollen varieties that create truly distinctive spirits impossible to replicate elsewhere.

Regardless of variety, always choose raw, unfiltered honey for whiskey production. Commercial processed honey often undergoes high-temperature pasteurization that destroys delicate aromatics crucial to developing complex spirits. The slightly higher cost of premium honey represents a minimal investment compared to the time and effort involved in distillation, and directly translates to superior flavor in your finished product.

What alcohol percentage should I expect from this recipe?

Honey fermentation typically yields a wash of 10-14% alcohol by volume (ABV) depending on your honey concentration and yeast strain’s alcohol tolerance. After distillation, your spirit run hearts fraction will generally contain between 60-80% ABV (120-160 proof). Most distillers dilute this to approximately 40-50% ABV (80-100 proof) for aging and bottling, which provides the optimal balance between flavor perception and alcohol strength. For more details, you can check out how to make moonshine.

Higher proofs maintain better shelf stability and can be diluted later to preference, but may mask subtle honey notes behind strong alcohol presence. Lower proofs (below 40% ABV) allow honey character to dominate but may not integrate well with oak aging and risk potential microbial stability issues during long-term storage. The sweet spot for most honey whiskey moonshine tends to be 45-50% ABV, where alcohol provides structure without overwhelming delicate honey aromatics. For those interested in understanding more about the difference between spirits and moonshine, further reading can provide valuable insights.

How do I know when to make the “cuts” during distillation?

Making proper cuts between fractions is perhaps the most crucial skill in distillation, particularly with delicate spirits like honey whiskey. While temperature provides a rough guideline, experienced distillers rely primarily on smell and taste to determine transition points. The shift from heads to hearts is marked by a transformation from sharp, solvent-like aromas to clean, sweet honey notes – this transition typically occurs after collecting about 150ml of foreshots and 15-20% of your expected total yield as heads. Understanding the three main parts of a still can also enhance your ability to make precise cuts.

The hearts-to-tails transition is more subtle, detected when the clean honey character begins fading and a more watery, sometimes cereal-like character emerges. This typically coincides with declining alcohol percentage in your distillate, often around 45-50% ABV depending on your still design. When in doubt, make conservative cuts and set questionable fractions aside in separate containers – you can always evaluate them later and decide whether to include them in your final product or save them for redistillation in future batches.