When to Stop Distilling: 5 Warning Signs Every Moonshiner Should Know

- Key Takeaways: When to Stop Distilling Immediately

- Alcohol vapor is highly explosive – always shut down your still at the first sign of leaks to prevent fire hazards

- Temperature readings above 210°F/99°C generally indicate you’ve collected all usable alcohol from your wash

- When ABV drops to 10-15% in your distillate, you’ve reached the “tails” and should consider ending your run

- Never leave a still unattended during operation – commercial distillers always maintain constant supervision

- Using proper equipment (copper or 304 stainless steel) is essential for both safety and product quality

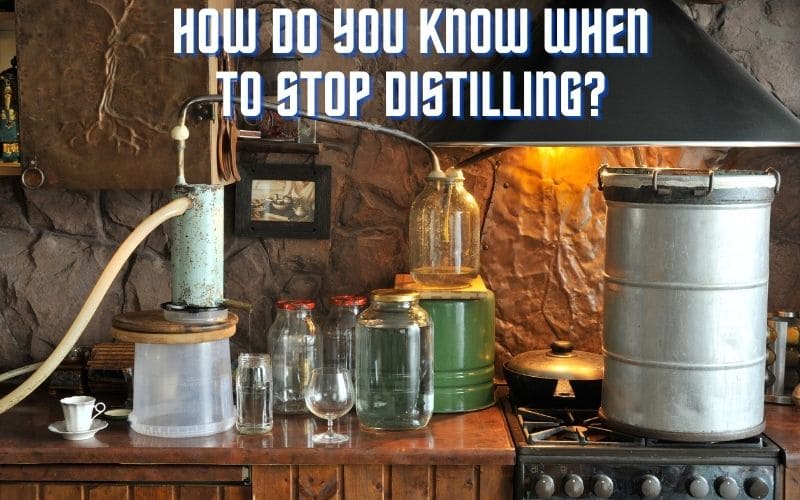

Knowing exactly when to stop your distillation run can make the difference between a quality product and wasted effort—or worse, a dangerous situation. While the art of moonshining requires practice and intuition, there are clear warning signs that demand immediate attention from even the most experienced distiller.

The most critical factor in home distillation is safety. At Moonshine Distiller, we’ve helped countless craft spirits enthusiasts understand the essential warning signs that require an immediate shutdown of operations. Whether you’re making whiskey, rum, or any other spirit, recognizing these signals could prevent serious accidents and ensure the quality of your final product.

Safety Essentials At-a-Glance

REMEMBER: Alcohol vapor is highly explosive. Commercial distillers always inspect equipment before use and shut down immediately if any leaks develop. This isn’t being overcautious—it’s standard industry practice that saves lives.

Distillation involves heat sources, potentially explosive alcohol vapor, and highly flammable ethyl alcohol. The combination demands respect and vigilance. A heat source malfunction, leaky still, or spilled collection vessel could quickly turn into a disaster if you’re not paying attention to the warning signs.

The distillation process follows predictable patterns of temperature, output, and quality. Understanding these patterns helps you recognize when something isn’t right—or when you’ve simply reached the natural end of a successful run. Stopping at the right time is as much about safety as it is about creating a quality product. Try out some of these awesome ingredients we highly recommend.

Let’s examine the five critical warning signs that tell you it’s time to stop distilling immediately, whether due to safety concerns or because you’ve collected all the good spirits your wash has to offer.

Dangerous Signs That Demand Immediate Shutdown

“7 Safety Tips for Distilling at Home” from www.whiskeystillpro.com and used with no modifications.

When it comes to distillation, prevention is always better than dealing with an emergency. Being able to recognize these warning signs early can prevent equipment damage, product contamination, or serious safety incidents. Never ignore these indicators, even if you’re nearing the end of what seems like a perfect run.

1. Temperature Spikes Beyond Control

Temperature is perhaps your most reliable indicator of when to stop distilling. As alcohol evaporates from your wash at a lower temperature than water, monitoring temperature changes tells you exactly what’s happening inside your still. When your thermometer reading approaches 210°F (99°C), you’ve likely extracted most of the ethanol from your wash.

Normal Temperature Ranges for Different Still Types

Different still designs operate at different optimal temperature ranges. Pot stills typically run between 172-212°F (78-100°C) throughout a complete run. Reflux stills often maintain a more consistent column temperature, usually between 170-180°F (77-82°C) for high-proof neutral spirits. Understanding your equipment’s normal operating range is essential for recognizing abnormal conditions.

Why Sudden Temperature Changes Signal Danger

A sudden spike in temperature without adjusting your heat source indicates you’ve likely exhausted the alcohol content in your wash. This creates a dangerous situation as your still begins to operate essentially as a pressure cooker filled with water. If you notice the temperature climbing rapidly past 200°F (93°C) without stabilizing, it’s time to end your run.

Even more concerning is when temperature spikes coincide with pressure increases. This combination can quickly create unsafe conditions where connections may fail or, in extreme cases, where the still itself becomes compromised. Always prioritize safety over trying to squeeze out those last few drops of spirit.

| Temperature Reading | What’s Happening | Action Required |

|---|---|---|

| 172°F (78°C) | Ethanol beginning to vaporize | Continue distilling (starting point) |

| 180-190°F (82-88°C) | Hearts phase typically in progress | Continue with careful monitoring |

| 195-205°F (91-96°C) | Entering tails phase | Consider stopping soon |

| 210°F+ (99°C+) | Mostly water being distilled | Stop distilling |

How to Properly Monitor Your Still’s Temperature

Always use a reliable thermometer positioned at the correct location for your still type. For pot stills, monitor the temperature at the top of the column or just before the condenser. For reflux stills, you’ll want to track temperatures at both the top and bottom of your column. Digital thermometers with alarms can be particularly helpful for warning you when temperatures approach your predetermined stopping points.

2. Unusual Odors or Chemical Smells

Your nose is one of your best tools for identifying when something’s going wrong during distillation. While some aromas are expected and even desirable during different phases of distilling, certain smells signal serious problems that require immediate shutdown.

The “Good” vs. “Bad” Smells During Distillation

During a normal run, you’ll detect different aromas as you move from foreshots through heads, hearts, and tails. The foreshots often carry a harsh, solvent-like smell that should never be consumed. As you progress to the heads, the aroma becomes less harsh but still contains volatile compounds with sharp, acetone-like notes. The hearts phase brings the clean, desirable aromas of your spirit, while tails develop a wet cardboard or oily smell.

However, any smell resembling burning plastic, rubber, or chemicals that aren’t part of the normal distillation profile indicates a serious problem. These odors could signal that parts of your still are overheating, gaskets are melting, or that contamination has occurred in your wash. If you detect any of these unusual smells, stop distilling immediately.

Identifying Methanol and Other Harmful Vapors

Methanol, which boils at a lower temperature than ethanol (148°F/64.7°C vs 172°F/78.3°C), has a distinctively sweet, fruity smell that can be deceptively pleasant. While small amounts are normal in the foreshots, an overwhelming sweet solvent smell throughout your run could indicate dangerous levels of methanol or other toxic compounds. This is particularly common when fermenting fruits or using recipes high in pectin without proper preparation, such as when making peach brandy moonshine. When in doubt about any unusual sweet solvent smell, it’s safer to shut down and investigate.

3. Pressure Building in Your System

Distillation should operate at ambient or slightly positive pressure in most home setups. Any signs of excessive pressure building in your system require immediate attention and often necessitate shutting down your still.

Safe Pressure Levels for Home Distillation

Unlike commercial operations that sometimes use vacuum or pressure distillation, home distillers should maintain near-atmospheric pressure throughout their system. Your setup should allow vapors to flow freely through the column and condenser without resistance. Most home stills aren’t designed to withstand significant pressure, and attempting to operate under pressure can create dangerous conditions. For those interested in enhancing their distillation with flavors, consider trying this apple cider moonshine recipe to add a cozy and crisp taste to your homemade spirits.

If your still includes a pressure gauge, keep a close eye on it throughout your run. For stills without gauges, you’ll need to watch for visual and auditory cues that pressure might be building. Hissing sounds, vibrating components, or vapor escaping from unexpected places all indicate potentially dangerous pressure buildup.

Warning Signs of Blockages or Constrictions

“Safety Tips for “Moonshiners …” from www.clawhammersupply.com and used with no modifications.

Pressure most commonly builds when something is blocking the normal vapor path through your still. Common culprits include collapsed packing in a reflux column, blockage in the condenser, or a kink in the output tube. You might notice reduced output flow, gurgling sounds, or erratic temperature readings when blockages occur. If you’re interested in learning more about moonshine and its variations, check out this apple cider moonshine recipe for a cozy and crisp fall sipper.

Another warning sign is when your cooling water becomes excessively hot while flowing through the condenser. This suggests your condenser isn’t efficiently converting vapor back to liquid, creating back pressure in your system. If your condenser output water is steaming or too hot to touch comfortably, you need to increase cooling water flow or shut down. For more tips on crafting spirits, check out these amazing recipes.

How to Safely Release Excess Pressure

If you detect pressure building in your still, your first step should be to reduce or remove the heat source immediately. Never attempt to release pressure by opening the still while it’s hot or under pressure. The sudden release of hot vapor can cause severe burns or create fire hazards if alcohol vapor contacts an ignition source.

For minor pressure issues, reducing the heat and ensuring your cooling water is flowing adequately may resolve the problem. However, if pressure continues to build or if your still makes unusual noises even after reducing the heat, proceed with a full shutdown. Allow everything to cool completely before investigating the cause of the pressure buildup. For more on maintaining your still, check out our guide on apple cider moonshine.

4. Leaks or Vapor Escape

Perhaps the most dangerous situation during distillation is when alcohol vapor escapes from your still through unintended paths. Commercial distillers inspect their equipment for leaks before every run, and immediately shut down if a leak develops during distillation. You should follow this same protocol for home distilling.

Common Leak Points to Watch

Leaks typically occur at connection points where different parts of your still come together. The most common trouble spots include gasket seals, threaded connections, clamps, and solder joints. Before each run, carefully inspect these areas for signs of wear, corrosion, or improper seating that might allow vapor to escape.

During operation, periodically check these same points for any signs of leakage. Alcohol vapor leaks might appear as small wisps of steam, or they might create wet spots where vapor condenses on the outside of your still. Some distillers use a flashlight to help spot these sometimes-subtle signs of vapor escape. For more on ensuring safety during distillation, check out these distillation safety tips.

Why Alcohol Vapor Creates Explosion Risks

Alcohol vapor is invisible, highly flammable, and can travel significant distances from your still to reach an ignition source. At certain concentrations in air (roughly 3.3% to 19% for ethanol), alcohol vapor can explode with devastating force if ignited. This invisible danger is why professional distillers maintain such strict protocols around leak prevention and detection.

The risk is compounded by the fact that many home distillers use open flame heat sources, creating both the potential fuel (alcohol vapor) and ignition source (flame) for a serious accident. Even electric heating elements can spark under certain conditions, providing enough energy to ignite escaped vapor. For a safer alternative, consider trying a peach brandy moonshine recipe that can be made with electric heat sources.

Emergency Response for Different Types of Leaks

If you detect any vapor leak during operation, shut down your heat source immediately. Don’t try to tighten connections or adjust your equipment while it’s hot – this can actually make the situation worse by creating sparks or causing burns. Follow a proper shutdown procedure by turning off the heat, ensuring adequate ventilation, and allowing the system to cool completely before attempting repairs.

For liquid leaks at the collection point, the response depends on the severity. Minor drips can often be addressed by adjusting collection vessels, but if alcohol is pooling near your heat source or creating slip hazards, end your run immediately. Remember that high-proof alcohol is extremely flammable in both liquid and vapor forms.

After any leak, thoroughly inspect your equipment before the next run. Replace gaskets, repair joints, or upgrade components as needed. Safety investments always pay off in the long run, both in peace of mind and in protecting your craft.

5. Changes in Distillate Appearance

The appearance of your distillate provides valuable information about when you’ve reached the end of the desirable portion of your run. Monitoring color, clarity, and consistency helps you determine the optimal stopping point for quality purposes. For example, when crafting flavored varieties like strawberry lemonade moonshine, maintaining the right appearance is key to achieving the best taste.

Clear Signs of Contamination

Pure distillate should be clear without cloudiness, floating particles, or unusual coloration. If you notice any of these issues, particularly sudden changes during what seemed like a normal run, it indicates potential contamination. This might come from damaged equipment, problematic ingredients, or fermentation gone wrong.

Particularly concerning are blue-green tints (potential copper compounds), milky appearance (oils or other contaminants), or metallic sheen (possible equipment degradation). These visual indicators suggest compounds that could be harmful if consumed and warrant immediate shutdown for investigation.

SAFETY RULE: When in doubt, throw it out. No batch of moonshine is worth risking your health or safety. Quality distillers prioritize purity and safety above all else.

Why You Must Always Discard Foreshots

The first portion of your distillate (approximately 100-150ml per 20L wash) contains methanol and other toxic compounds that must always be discarded. These foreshots often have a sharp, solvent-like smell and a harsh taste. Never be tempted to keep this portion just to increase your yield – the health risks aren’t worth it.

After the foreshots come the heads, which contain a mix of ethanol and some less desirable compounds. While not toxic like foreshots, heads often contribute harsh flavors. Many distillers collect heads separately for redistilling later or for use in cleaning products.

Color and Clarity Changes That Signal Problems

As you progress through your run, you’ll eventually reach the tails – the point where the quality of your distillate noticeably declines. Tails often appear slightly cloudy when mixed with water (unlike hearts, which stay clear). This “louching” effect occurs because tails contain more oils and fusel alcohols that don’t dissolve well in water.

Another key indicator is the ABV of your distillate. When your alcohol content drops to around 10-15% (20-30 proof), you’ve typically reached deep into the tails. At this point, continuing to distill yields diminishing returns in both quantity and quality. Most experienced distillers choose to stop their run at this point, as the additional yield isn’t worth the time, energy, and potential quality compromise.

The Safe Shutdown Procedure Every Distiller Must Know

“Distilled spirit | Definition, History …” from www.britannica.com and used with no modifications.

Knowing how to properly shut down your still is just as important as knowing when to do it. A controlled, methodical shutdown protects both your equipment and your safety, whether you’re ending a run normally or responding to an emergency situation. For those interested in exploring more about distilling, consider trying this Peach Brandy Moonshine recipe to enhance your craft.

Step-by-Step Emergency Shutdown Process

- First, remove all heat sources immediately – turn off electric elements, extinguish flame sources, or disconnect power

- Ensure adequate ventilation in your distilling area to disperse any vapors

- Maintain cooling water flow through your condenser until the still cools down

- Don’t attempt to disassemble or adjust anything until the entire system has cooled

- Secure your collected distillate in appropriate containers away from heat sources

- Document what happened for future reference, particularly if responding to an equipment issue

The key difference between a normal shutdown and an emergency shutdown is the immediacy of heat removal. During a normal end-of-run, you might gradually reduce heat to ease the transition. In an emergency, removing heat as quickly as possible becomes the priority.

Cooling and Securing Your Equipment

After shutting down the heat source, your still needs time to cool properly. Never rush this process by applying cold water to the outside of a hot still – the thermal shock can damage or warp your equipment. Instead, allow natural cooling while maintaining water flow through your condenser. Don`t forget the must have accessories and supplies we always recommend.

Once cooled, drain any remaining liquid from your still according to appropriate disposal methods for your area. Remember that leftover wash still contains alcohol and should never be dumped where it might reach waterways or wildlife. Many distillers compost spent wash or use it as animal feed (where legally permitted).

When to Restart vs. When to Troubleshoot

If you’ve shut down due to reaching the natural end of your run (tails with diminishing returns), you can clean your equipment and prepare for your next batch without special measures. However, if your shutdown was prompted by equipment issues, unusual smells, leaks, or other safety concerns, a thorough inspection is mandatory before your next run. For more information on safety, check out these safety tips for moonshiners.

| Shutdown Reason | Before Restarting | Risk Level |

|---|---|---|

| Normal end of run (tails) | Standard cleaning | Low |

| Minor temperature fluctuations | Check heating system | Medium |

| Vapor leaks | Complete inspection and repair | High |

| Unusual odors/contamination | Thorough system cleaning and testing | High |

Pay special attention to gaskets, connection points, and seals after any emergency shutdown. These components often degrade first and present the highest risk of future problems. Many experienced distillers keep spare gaskets and seals on hand for immediate replacement rather than trying to stretch the lifespan of worn components.

Consider a “dry run” without alcohol after making repairs – running your system with just water can help identify any remaining issues before committing valuable fermented wash to a potentially problematic still. If you’re looking for a refreshing twist, you might want to try making strawberry lemonade moonshine once your system is up and running smoothly.

Prevention: Better Than Cure

The best way to avoid emergency shutdowns is through meticulous preparation and maintenance of your distillation equipment. Developing a proactive approach to still maintenance and operation significantly reduces the likelihood of encountering dangerous situations that demand immediate shutdown. For those interested in exploring different flavors, consider trying peach brandy moonshine as a sweet southern spirit to enjoy safely at home.

- Inspect all gaskets and seals before each run for signs of wear or degradation

- Check all connections and fittings to ensure they’re secure but not overtightened

- Verify cooling water systems function properly with adequate flow rates

- Remove any potential blockages from condensers or tubing

- Test heating systems at low settings before committing to a full distillation run

- Keep a distillation log to track performance and identify developing issues

Establishing a regular maintenance schedule extends the life of your equipment while ensuring safer operation. Many problems that cause emergency shutdowns develop gradually and can be caught during routine inspections before they become dangerous.

Remember that quality distillation equipment represents a significant investment. Protecting that investment through proper maintenance and knowing when to stop distilling before damaging your still makes good financial sense, not just safety sense. For those interested in exploring unique flavors, crafting the best caramel moonshine can be a delightful endeavor.

Essential Maintenance Checks Before Each Run

- Pressure test your system using water to identify potential leaks

- Ensure thermometers are calibrated and reading accurately

- Check all clamps, screws, and fasteners for proper tightness

- Inspect heating elements for signs of corrosion or damage

- Verify condenser tubes are clear and unobstructed

These simple checks take just minutes but can prevent hours of frustration and potential danger. Creating a pre-flight checklist similar to what pilots use before takeoff ensures you don’t miss critical safety steps in your excitement to start a new batch.

Consider investing in a carbon monoxide detector and alcohol vapor detector for your distilling space. These safety devices provide early warning of dangerous conditions that might not be immediately obvious to your senses, especially after spending time in the distilling environment where your nose can become desensitized to certain smells. For more safety tips, check out the 10 most important safety tips for moonshiners.

Another preventative measure is ensuring proper ventilation in your distilling area. Adequate airflow helps dissipate any minor vapor leaks before they can reach dangerous concentrations and reduces the risk of carbon monoxide buildup from heating sources.

Creating Your Distillation Safety Checklist

Develop a written safety protocol and checklist tailored to your specific equipment and process. Include pre-run checks, monitoring points during distillation, shutdown procedures, and emergency response plans. Having these steps documented reduces the likelihood of skipping important safety measures and provides clear guidance during potential emergencies when stress might affect your decision-making.

Must-Have Safety Equipment Within Reach

Every distilling operation should maintain specific safety equipment nearby: a properly rated fire extinguisher (Class B for alcohol fires), heat-resistant gloves, safety goggles, and first aid supplies. For larger operations, consider a fire blanket and emergency shower or eyewash station. The time to acquire these items is before you need them, not during an emergency. For those interested in exploring more about moonshine, check out our Peach Brandy Moonshine recipe.

Common Questions About Distilling Emergencies

“Emergency DIY Water Distillation for …” from www.youtube.com and used with no modifications.

Even experienced distillers occasionally face situations that require them to stop distillation unexpectedly. Understanding the answers to these common questions helps you respond appropriately when challenges arise.

How quickly should I shut down if I notice one of these warning signs?

Safety concerns like leaks, unusual odors, or pressure buildup require immediate shutdown – don’t finish measuring your current collection jar or wait to reach a convenient stopping point. Quality issues like reaching the tails allow more flexibility, where you might choose to collect a bit more before shutting down based on your specific product goals and energy costs.

Can I save any part of my batch if I need to shut down mid-run?

If your shutdown is due to equipment issues rather than contamination concerns, the distillate collected before the problem occurred is usually still usable. Keep accurate notes about where in the process you stopped, as this will help you determine whether you’re still in the heads, hearts, or tails if you’re able to restart. For those interested in exploring different flavors, consider trying out a peach brandy moonshine recipe during your next run.

For shutdowns caused by contamination concerns or potentially dangerous conditions, the safest approach is to discard the entire batch. While this can be disappointing, no amount of moonshine is worth risking your health or safety.

What’s the biggest mistake new distillers make when responding to warning signs?

The most common error is trying to “fix” problems while the still is hot or running. This creates unnecessary risks of burns, vapor ignition, or equipment damage. Always complete a proper shutdown first, then troubleshoot after everything has cooled. Remember that alcohol vapor is invisible and can ignite from unexpected sources like static electricity or hot metal surfaces. For those interested in expanding their distillation repertoire, consider trying your hand at making peach brandy moonshine, a sweet southern spirit you can craft at home.

How do I know if my still needs repairs before using it again?

After any emergency shutdown, conduct a thorough inspection once everything has cooled. Look for warped metal, damaged gaskets, loose fittings, or corrosion. Pressure testing with water before your next alcohol run can identify leaks safely. When in doubt about a component’s integrity, replace it rather than risking a more serious failure during operation.

Are there any warning signs that are unique to specific types of stills?

Reflux stills may show different symptoms than pot stills when problems develop. In reflux columns, packing collapse or flooding can cause sudden pressure changes and temperature fluctuations at the top of the column. Plate stills might experience “weeping” where liquid falls between plates rather than vaporizing properly. Each still design has its own potential failure points, so research your specific equipment type to understand its unique warning signs. For those interested in exploring different moonshine flavors, try this apple cider moonshine recipe for a cozy and crisp fall sipper. Check out the quality built home stills we definitely recommend.

Pot stills, while simpler, can be more prone to “puking” where the wash boils up into the column, requiring immediate heat reduction. This is often preceded by large, unstable bubbles forming in the boiler, so keeping visual tabs on your wash can provide early warning. For those interested in experimenting with flavors, you might want to try making green apple moonshine as it offers a crisp and tart homemade delight.

Regardless of your still type, developing an intimate knowledge of how it normally operates helps you quickly identify when something isn’t right. The sounds, smells, and patterns of a healthy distillation run create a baseline against which problems become readily apparent. Take a look at some of this cool moonshine merch we like.

Understanding when to stop distilling isn’t just about maximizing yield or quality—it’s fundamentally about creating a safe environment for practicing your craft. By respecting these warning signs and implementing proper procedures, you’ll enjoy a safer, more productive distilling experience for years to come. Moonshine Distiller is committed to helping you master these essential skills through quality equipment and educational resources.