How Do You Make Moonshine Taste Smooth? Enjoy Smooth Drinks

Key Takeaways

- Producing smooth moonshine requires careful attention to the distillation process, particularly making proper cuts between heads, hearts, and tails.

- Quality ingredients directly impact the final taste – using filtered water and high-grade grains or fruits creates a cleaner base flavor profile.

- Carbon filtration and proper aging with oak chips are two of the most effective methods for transforming harsh moonshine into a smooth sipping experience.

- Full Throttle Distillery specializes in creating exceptionally smooth moonshine using traditional techniques combined with modern filtration methods.

- Flavor additions like fruits and spices not only enhance taste but can effectively mask the harshness in less-than-perfect batches.

The Secret to Smooth Moonshine: Why Most Home Distillers Get It Wrong

“8-Gallon Moonshine Still with 2″ Head …” from moonshinedistiller.com and used with no modifications.

Making smooth moonshine isn’t just about following a recipe – it’s about understanding the science and artistry behind distillation. The difference between harsh, headache-inducing hooch and velvety, sippable spirit often comes down to a few critical details that many home distillers overlook. At Full Throttle Distillery, we’ve perfected these techniques through years of dedicated craftsmanship, creating moonshine that glides across your palate instead of burning it. Understanding the chemistry behind moonshine production is essential for creating a product that doesn’t make your eyes water with every sip.

The smoothness of moonshine is primarily determined during the distillation process, not after it’s bottled. Many enthusiasts try to fix a harsh batch with flavoring or aging when the real problems occurred much earlier. Temperature control, proper equipment, and patience during collection are fundamental elements that separate master distillers from amateurs. Rushing any stage of the process almost guarantees a rough final product that no amount of flavoring can fully salvage.

Another common misconception is that all moonshine is supposed to be harsh. This couldn’t be further from the truth. Traditional, well-crafted moonshine should have a clean, distinctive character without the burning sensation that many associate with illegal or poorly-made spirits. The smoothness comes from meticulous attention to detail throughout the entire process – from fermentation to filtration.

5 Major Factors That Make Moonshine Taste Harsh

“What Is Moonshine: Making Moonshine …” from www.thrillist.com and used with no modifications.

Understanding what causes harshness is your first step toward creating a smoother product. The burning sensation and unpleasant aftertaste in moonshine aren’t inevitable – they’re symptoms of specific issues that can be addressed and eliminated.

Poor-Quality Ingredients Ruin Your Batch From the Start

Using low-grade fermentables and contaminated water sets your moonshine up for failure before you even begin distilling. The quality of your ingredients directly influences the final flavor profile of your spirit. Impurities in sugar, inferior grains, or tap water containing chlorine and minerals will carry through the distillation process and manifest as off-flavors in your final product. For those interested in a traditional approach, you might consider this traditional corn-based moonshine recipe to ensure quality ingredients.

Always start with filtered water and the highest quality fermentables your budget allows. For corn-based moonshine, consider using food-grade corn rather than feed corn, which may contain mold and pesticides that impact flavor. Remember that moonshine amplifies both the good and bad characteristics of your ingredients, so cutting corners here will undoubtedly affect smoothness.

Improper Distillation Temperature Control

Temperature management during distillation isn’t just important – it’s absolutely crucial for creating smooth moonshine. Running your still at temperatures that are too high causes excessive vapor production, pushing unwanted compounds into your collection jar alongside the ethanol. These compounds, including fusel oils and certain esters, contribute significantly to the burning sensation associated with poorly-made spirits.

A properly managed distillation run maintains consistent, controlled temperatures, typically keeping the head temperature between 172-180°F (78-82°C). This temperature range allows for the proper separation of alcohols and congeners, facilitating cleaner collection of the desirable ethanol. Investing in accurate thermometers and taking detailed notes on each run will help you identify your equipment’s sweet spot for producing the smoothest results.

Neglecting the “Cuts” (Heads, Hearts, and Tails)

Perhaps the single most important factor in creating smooth moonshine is making proper cuts during collection. The distillate that comes off your still isn’t uniform throughout the run – it emerges in distinct phases known as heads, hearts, and tails, each with dramatically different characteristics. The heads contain volatile compounds like methanol and acetone that contribute to harsh flavors and potential health hazards. The tails contain fusel oils and other heavier compounds that add an unpleasant aftertaste.

Only the hearts section – the middle portion of your run – should be retained for drinking. This clear, clean-tasting ethanol is what gives quality moonshine its smooth character. Many beginners make the mistake of being too greedy, collecting too much of the heads or tails in an attempt to increase yield. This false economy results in harsh spirits that no amount of flavoring or aging can fully redeem.

Learning to identify each phase takes practice and attention to detail. The heads typically have a sharp, solvent-like smell and taste, while the hearts have a clean, sweet aroma. When the distillate begins to develop a wet cardboard or oily quality, you’ve reached the tails and should stop collecting or switch containers to separate these portions. For those interested in the legal aspects of distilling, you might want to learn about stills legality in the US.

Using Contaminated Equipment

Cleanliness isn’t just next to godliness – it’s essential for smooth moonshine. Even microscopic contaminants in your fermentation vessel, still, or collection containers can introduce off-flavors that persist through distillation. Bacteria, mold, or residue from previous batches can all contribute harsh notes to your final product. Always sanitize equipment thoroughly with food-grade sanitizers, avoiding soap residues that might affect flavor.

Pay special attention to copper stills, which develop verdigris (copper oxide) between uses. This greenish substance must be completely removed before distilling as it introduces metallic flavors. Plastic fermenters can harbor bacteria in micro-scratches, so inspect them carefully and replace if they show signs of wear. Remember that what you can’t see can still ruin your moonshine’s smoothness.

Skipping Proper Filtration Steps

Many distillers underestimate the impact that post-distillation filtration has on smoothness. Raw moonshine contains microscopic particles and dissolved compounds that contribute to harshness, even after careful distillation. Multiple filtration steps can remove these impurities, significantly improving mouthfeel and reducing burn. Without proper filtration, even well-distilled moonshine can retain a rough edge that diminishes the drinking experience.

Perfect Your Distillation Process for Smoother Results

“20 Gallon 220v Electric Moonshine Still …” from www.thedistillerynetwork.com and used with no modifications.

Mastering distillation techniques is the foundation of creating silky-smooth moonshine. No amount of aging or flavoring can fully compensate for errors made during this critical phase. The distillation process is where you separate the desirable compounds from those that cause harshness and off-flavors.

Finding the Sweet Spot Temperature Range

Temperature control is one of the most nuanced aspects of creating smooth moonshine. Different compounds vaporize at specific temperatures, which allows for their separation during distillation. For optimal results, maintain your still’s head temperature between 172-180°F (78-82°C) during the collection of hearts. This range efficiently vaporizes ethanol while leaving behind many of the heavier compounds that contribute to harsh flavors.

A slow, patient distillation run at proper temperatures yields significantly smoother results than a quick, hot run. Aim for a drip rate of about 2-3 drops per second during the hearts collection phase. This patience allows for better separation and clearer distinctions between the heads, hearts, and tails sections. Invest in an accurate digital thermometer that attaches to your still’s head – the few extra dollars spent here will pay dividends in smooth moonshine.

How to Properly Make Your Cuts

Making precise cuts between the different phases of your distillation run is perhaps the single most important skill in creating smooth moonshine. This process requires attention, patience, and a willingness to sacrifice quantity for quality. Remember that you’re not trying to extract every possible drop of alcohol – you’re selecting only the cleanest, purest portion. Understanding the three main parts of a still can greatly aid in making these cuts effectively.

1. Identifying and Removing the Heads

The first liquid that comes from your still contains volatile compounds like methanol, acetone, and ethyl acetate. These compounds not only taste harsh but can be dangerous in high concentrations. The heads typically represent about 5-10% of your total expected yield and have distinctive characteristics: a sharp, solvent-like smell reminiscent of nail polish remover or paint thinner.

Collect the heads in a separate container and set aside – these can be used for cleaning purposes or discarded, but should never be consumed. The transition from heads to hearts isn’t always abrupt; there’s often a gradual improvement in quality. Many experienced distillers collect in small jars (4oz or smaller) during this transition phase, allowing them to precisely identify where the heads end and the hearts begin through later testing.

2. Collecting Only the Hearts

The hearts are the crown jewels of your distillation run – the clean, pure ethanol that forms the basis of smooth moonshine. This portion typically begins when the harsh solvent smell dissipates and is replaced by a sweeter, cleaner aroma. The liquid will taste noticeably smoother and lack the burning sensation characteristic of heads.

Hearts typically make up about 30% of your total potential yield from a run. While it’s tempting to extend this collection to increase your output, being conservative with your cuts will significantly improve quality. The hearts should have little to no burn when tasted (after appropriate dilution), with a clean finish and subtle sweetness from the grain or fruit used in your mash. For more insights on tasting moonshine, you can explore how to taste moonshine like an expert.

3. When to Stop Before the Tails

As your run progresses, the quality will eventually begin to deteriorate as you enter the tails section. This transition is marked by a drop in alcohol content and the emergence of oily, sometimes earthy flavors. The clear, water-like appearance of hearts gives way to a slightly cloudy liquid, and you may notice an oily film or droplets forming on the surface of your collection jar.

The exact point to stop collecting hearts depends somewhat on personal preference and intended use. Some distillers make a “hearts-tails transitional cut” that can be redistilled later or used for lower-quality batches. For the smoothest possible moonshine, however, it’s best to be conservative and stop collecting as soon as you detect changes in clarity, smell, or taste. The proof will typically drop below 100 (50% ABV) as you enter the tails section. If you’re curious about the traditional methods used in making moonshine, you might want to explore the traditional corn-based moonshine recipe.

7 Proven Filtration Methods to Remove Harsh Flavors

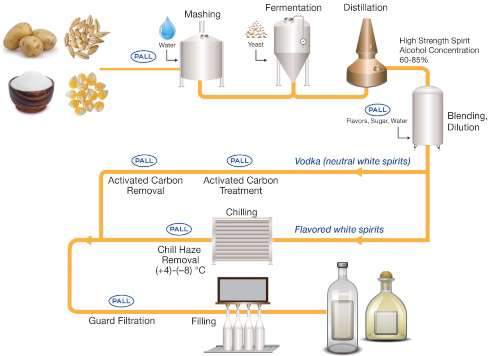

“Spirit Filtration Solutions for Food …” from www.pall.com and used with no modifications.

Even after careful distillation, additional filtration can transform good moonshine into exceptional moonshine. These methods remove residual impurities and compounds that contribute to harshness. Many commercial distilleries employ multiple filtration techniques to achieve the smoothest possible product. For those interested in the main parts of a still, understanding the equipment can also enhance the distillation process.

Spice Combinations That Create Depth

Beyond traditional flavorings, certain spice combinations can transform your moonshine into a complex, smooth experience. Cinnamon, vanilla, nutmeg, and cloves work harmoniously to create depth while masking any residual harshness. These warm spices don’t just add flavor – they create a sensory distraction that draws attention away from the alcohol bite and toward their aromatic qualities.

“Traditional moonshiners often used spices not just for flavor but as a practical way to make rough batches more palatable. What began as necessity evolved into beloved family recipes passed down through generations.” – Appalachian Distilling Traditions

For a sophisticated spice blend, try combining 3 cinnamon sticks, 1 split vanilla bean, 5 whole cloves, and a quarter teaspoon of freshly grated nutmeg per quart of moonshine. Allow these spices to infuse for at least 3 days, tasting daily until you reach your desired flavor intensity. The longer they steep, the more the spices will round out the sharp edges of your spirit.

Unexpected spices like star anise, cardamom, or even pink peppercorns can create distinctive flavor profiles that elevate your moonshine from ordinary to extraordinary. These more exotic additions work particularly well with fruit-infused bases, creating complex layers of flavor that unfold gradually on the palate. Experiment with small batches before committing your entire production to a new spice combination. For more tips, you can explore how to taste moonshine like an expert.

Sweeteners That Balance Alcohol Bite

Strategic use of sweeteners does more than just add sugar – it fundamentally alters how your palate perceives alcohol. Honey, maple syrup, brown sugar, and agave nectar all contribute unique flavor characteristics while dampening the ethanol bite through chemical interactions with your taste receptors. For the smoothest results, add sweeteners after distillation and filtration, starting with small amounts (about 2-3 tablespoons per quart) and adjusting to taste. Remember that sweetness intensifies over time as flavors marry, so it’s better to start conservative and adjust upward as needed.

Creating Apple Pie Moonshine: The Perfect Beginner’s Recipe

Apple pie moonshine represents the perfect introduction to smooth, flavored spirits and is remarkably forgiving of less-than-perfect base moonshine. Start with a gallon of fresh apple cider and a quart of apple juice simmered with 3 cinnamon sticks, 1 teaspoon nutmeg, half teaspoon cloves, and 1 cup brown sugar. After cooling, mix with 750ml of moonshine (preferably filtered through carbon), then age with toasted oak chips for at least two weeks. The resulting spirit offers a smooth, dessert-like experience with the apple and spice flavors effectively masking any harshness from the base spirit. Full Throttle Distillery’s version uses this traditional approach enhanced by our proprietary filtration system, creating an exceptionally smooth finished product that highlights the natural sweetness of orchard-fresh apples.

Serving Techniques That Enhance Smoothness

“Easy Apple Pie Moonshine Recipe You Can …” from www.dreamilyrecipes.com and used with no modifications.

How you serve moonshine significantly impacts perceived smoothness, regardless of production quality. Temperature, glassware, dilution, and accompaniments all influence how your palate interprets the spirit. Mastering these serving elements allows you to present your moonshine in its best possible light, enhancing the drinking experience without modifying the spirit itself.

The Perfect Temperature for Different Moonshine Styles

Temperature dramatically affects how moonshine presents on your palate. Unflavored, traditional moonshine generally shows best at slightly below room temperature (around 60-65°F or 15-18°C), which softens the ethanol bite while still allowing the grain character to express itself. Any colder, and you’ll suppress the subtle flavors; any warmer, and the alcohol becomes more pronounced.

Flavored moonshines, particularly fruit-infused or creamy varieties, often benefit from chilling (40-50°F or 4-10°C). The lower temperature enhances perceived sweetness and creates a more refreshing experience, particularly welcome in summer months or with dessert-style moonshines. Some varieties, like apple pie or peach moonshine, can even be served over ice without significantly diluting their robust flavor profiles.

Glassware That Improves Taste Experience

The vessel from which you drink has a surprising impact on perceived smoothness. Traditional Mason jars, while culturally authentic, often do moonshine no favors with their wide openings that release ethanol vapors directly to your nose. Instead, consider tulip-shaped glasses that concentrate pleasant aromas while allowing harsh ethanol vapors to dissipate, or small whiskey glasses with slightly narrowed openings. The right glassware creates a more controlled delivery of aromas and flavors, significantly enhancing the perception of smoothness without changing the spirit itself.

Dilution: Finding Your Perfect Proof

Few people appreciate that proper dilution is often the key to unlocking moonshine’s full flavor potential. Most freshly distilled moonshine comes off the still between 100-160 proof (50-80% alcohol), which is simply too intense for most palates to appreciate fully. Diluting to 80-100 proof (40-50% alcohol) with filtered water not only reduces the ethanol burn but actually enhances flavor compounds through a process called “opening up.” Add water gradually, tasting as you go until you find your perfect balance of flavor intensity and smoothness. This simple step can transform harsh, overwhelming moonshine into an approachable, enjoyable sipping experience that reveals subtle flavor notes previously masked by alcohol intensity. For those interested in crafting their own, consider trying a traditional corn-based moonshine recipe to experience the full range of flavors.

From Harsh to Heavenly: Transforming Your Moonshine

“Ole Smoky Butter Pecan Moonshine …” from topshelfwineandspirits.com and used with no modifications.

Creating truly smooth moonshine isn’t about any single technique but rather the careful application of multiple approaches throughout the production process. Start with quality ingredients and meticulous distillation practices, particularly temperature control and proper cuts. Follow with appropriate filtration methods like carbon treatment, then consider aging with oak to add complexity while softening harsh edges. Finally, perfect your serving approach with appropriate temperature, glassware, and dilution. Each step builds upon the previous ones, creating a compounding effect that can transform harsh, burning spirits into remarkably smooth, complex moonshine that rivals commercial products. With patience and attention to detail, even home distillers can create moonshine that sips smoothly and delights the palate rather than punishing it.

Frequently Asked Questions (FAQ)

Understanding the finer points of moonshine production can be challenging, especially with so much misinformation circulating. These frequently asked questions address common concerns about creating smooth moonshine and troubleshooting problems in your production process.

The answers provided below represent a distillation of knowledge from experienced producers and the scientific principles underlying alcohol production. We’ve focused on practical information that directly impacts smoothness and drinking quality.

How long does moonshine need to age before it tastes smooth?

Unlike whiskey or bourbon that require years of aging, moonshine can show significant improvement in as little as 1-3 months when aged with oak. The transformation isn’t about time alone but about the interaction between the spirit and the wood compounds. Fresh-cut oak chips or cubes create faster changes than barrel aging due to increased surface area contact. For creative ways to package your aged moonshine, explore some moonshine packaging ideas.

Unflavored moonshine typically needs more aging time than flavored varieties to achieve smoothness. The clear spirit has nowhere to hide its flaws, so plan on 2-3 months minimum with oak for noticeable improvements in traditional corn or sugar shine. For those interested in exploring more about moonshine, you can read about how to taste moonshine like an expert. Fruit-infused or heavily spiced variations may require as little as 2-4 weeks to integrate flavors and achieve a smooth mouthfeel.

Remember that aging continues until you remove the oak elements, so taste regularly to prevent over-oaking, which can create excessive bitterness or astringency. The ideal aging duration finds balance between smoothness and retaining the characteristic qualities that make moonshine unique.

Can you make smooth moonshine without a proper still?

Creating genuinely smooth moonshine without proper distillation equipment presents significant challenges. Improvised stills typically lack temperature control, proper separation mechanisms, and safety features necessary for producing clean spirits. While technically possible to create alcohol without a traditional still, the results generally contain higher levels of congeners and fusel oils that contribute to harshness. For more insights, you can check out this discussion on how to drink moonshine.

If you’re unable to use proper distillation equipment, focus instead on flavoring and filtering commercially produced neutral spirits (where legal). This approach allows you to create custom-flavored spirits without the safety and quality concerns of improvised distillation. High-proof neutral grain spirit can serve as a base for infusions, providing the alcohol content without the technical challenges of distillation.

For those serious about creating smooth moonshine, investing in proper equipment isn’t just about quality—it’s about safety. Professional-grade or purpose-built hobby stills with temperature control, proper condensers, and appropriate materials (copper or stainless steel) are essential for consistent, safe results.

Why does my moonshine have a strange chemical taste?

A chemical taste in moonshine typically indicates the presence of heads (acetone, methanol, and other volatile compounds) in your final product. This most commonly results from improper cuts during distillation—specifically, collecting too early in the run before these compounds have been adequately separated. Revisit your cutting technique, being more conservative about when you start collecting the hearts portion.

Other potential causes include fermentation problems (bacterial infections or stressed yeast), contaminated equipment, or using ingredients containing unwanted chemicals. Ensure all fermentation equipment is properly sanitized, use quality ingredients (especially water and fermentables), and maintain appropriate fermentation temperatures to prevent stress compounds from forming.

Is it safe to drink moonshine that tastes harsh?

- Harshness alone doesn’t necessarily indicate danger, but extremely harsh flavors may signal improper distillation

- Chemical or solvent-like flavors could indicate the presence of methanol or other harmful compounds

- Metallic tastes might suggest contamination from improper still materials or construction

- Musty or moldy flavors could indicate unsafe fermentation conditions

When in doubt about safety, it’s always better to discard a questionable batch. No amount of smoothness is worth risking your health. Commercial distilleries like Full Throttle Distillery follow strict safety protocols and testing procedures to ensure every bottle meets both quality and safety standards.

The harshness in properly produced moonshine is typically due to ethanol concentration and congeners that, while unpleasant, aren’t inherently dangerous. These can be addressed through proper filtration, aging, dilution, and flavoring. However, true chemical off-flavors that suggest contamination or improper distillation should never be ignored.

Remember that historically, the dangers associated with moonshine stemmed primarily from improper equipment (like using radiators or lead-soldered containers) rather than the distillation process itself. Modern home distillers using appropriate materials and techniques can produce safe spirits, though legal restrictions remain in many jurisdictions.

What’s the difference between commercial and homemade moonshine’s smoothness?

Commercial distilleries like Full Throttle Distillery achieve consistent smoothness through precision equipment, scientific testing, and multi-stage filtration systems that aren’t typically available to home producers. Industrial carbon filtration systems, precise temperature controls, and analytical testing for congeners and impurities allow commercial operations to create remarkably consistent, clean spirits batch after batch.

Home producers often rely more heavily on traditional methods, including lengthy aging with wood and flavor additions to achieve smoothness. While these approaches can create excellent results, they typically produce more batch-to-batch variation. Commercial operations can also legally distill multiple times, creating higher purity base spirits before flavoring and aging.

That said, skilled home distillers who understand the science behind smoothness can sometimes create products that rival commercial offerings, particularly in small, carefully managed batches. The attention to detail possible in small-batch production can result in unique, character-filled moonshine with exceptional smoothness, even without industrial equipment.

For the smoothest possible moonshine experience without the learning curve, Full Throttle Distillery combines traditional recipes with modern purification techniques to create exceptionally smooth products that honor the heritage of moonshine while eliminating the harsh characteristics often associated with historical versions.