Proofing Moonshine: A Review Of The Top 4 Need-to-Know Facts

Introduction

Moonshine, with its illicit origins and unrefined allure, has captivated the imagination of many. In this article, we embark on a journey through the clandestine world of moonshine, uncovering the secrets of its production and the meticulous process of proofing. Whether you’re a novice enthusiast or a seasoned distiller, the art of proofing moonshine is an essential skill that distinguishes a quality concoction from amateur endeavors. Let’s delve into the intricate details and indispensable steps of how to proof moonshine, unlocking the essence of this age-old tradition.

Moonshine Fermentation

Overview

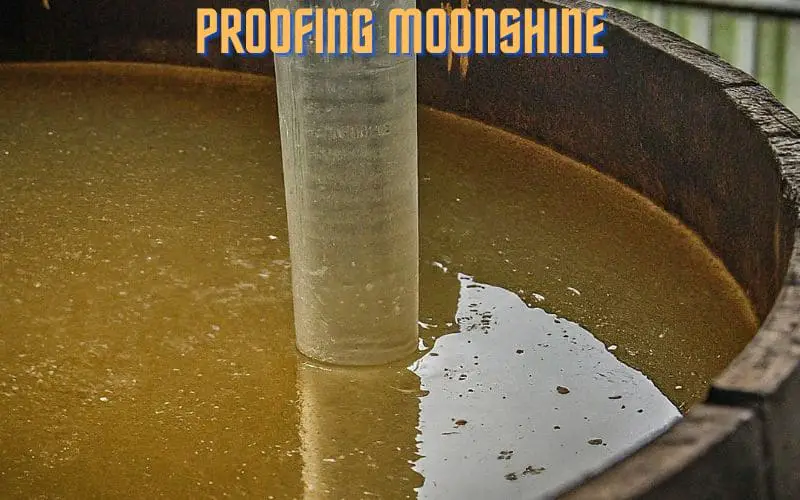

Before delving into the proofing process, understanding moonshine fermentation is crucial. Moonshine production begins with the fermentation of a grain mash, typically consisting of corn, barley, or rye. The fermentation process involves natural fermentation or the inclusion of yeast to convert the starches into alcohol. This initial step sets the foundation for the subsequent distillation and proofing processes, influencing the flavor and potency of the final moonshine product.

- Moonshine fermentation is a vital step in the production of high-quality moonshine.

- The fermentation process is responsible for converting the starches in the grain mash into alcohol.

- Corn, barley, and rye are the most commonly used grains in moonshine fermentation.

- Natural fermentation or the addition of yeast can be used to kickstart the fermentation process.

Distillation Process

Overview

The distillation process is a crucial step in the production of moonshine. It involves refining the fermented mash into a highly potent and palatable spirit. This process utilizes heat to vaporize the alcohol, which is then condensed to create a high-proof distillate. Understanding the intricate details of the distillation process serves as the foundation for mastering the art of proofing moonshine, guaranteeing both quality and safety in the final product.

- Boiling Point Variation: Exploring the specific boiling points of different components in the mash, understanding their impact on the distillation process.

- Fractional Distillation: Elaborating on the method of separating different components based on their boiling points to achieve a pure distillate.

- Heads, Hearts, and Tails: Delving into the distinctions and unique characteristics of each component during the distillation process.

- Temperature Control: Detailing the significance of precise temperature control during the distillation to achieve desired results.

- Equipment Selection: Discussing the importance of choosing appropriate distillation equipment for optimal results.

- Time Consideration: Highlighting the role of time in the distillation process and its impact on the final product.

For a Custom Copper Still Click Here To Contact Us With Your Needs

No Need To Worry! We Don’t Report Anything To Any Government Agency!

Proofing Hydrometer

Overview

The proofing hydrometer is an essential instrument used by distillers to measure the alcohol content in moonshine. It plays a key role in ensuring the quality and consistency of the distilled spirit. This specialized tool works by determining the specific gravity of the liquid, which in turn allows distillers to accurately calculate the alcohol by volume (ABV). By meticulously gauging the ABV, distillers are able to make precise adjustments to the potency of the moonshine, ensuring that it delivers a well-balanced and enjoyable drinking experience. Additionally, the proofing hydrometer enables distillers to adhere to regulatory standards and produce spirits that meet legal requirements. Its versatility and accuracy make it an indispensable asset for both hobbyist and professional distillers, providing the precision needed to achieve optimal results in the art of distillation.

Cutting Moonshine

Overview

Cutting moonshine involves the meticulous process of diluting the high-proof distillate to achieve the desired alcohol content and flavor profile. This step demands careful consideration and an understanding of the balance between potency and drinkability. By employing the correct cutting techniques, distillers can refine their moonshine into a smooth and harmonious libation, ready for consumption and appreciation.

- Alcohol Content: Understanding the ideal alcohol content for the specific type of moonshine being produced is crucial. It affects the overall flavor and potency of the final product.

- Flavor Profile: Dilution not only affects the alcohol content but also plays a significant role in shaping the flavor profile of the moonshine. Different dilution levels can bring out varying notes and characteristics.

- Proofing Techniques: Utilizing various proofing methods such as hydrometer readings, taste testing, and blending trials can aid in achieving the perfect balance of flavors and alcohol strength.

Conclusion

Through the age-old tradition of moonshine production, we meld innovation and history in each artisanal batch. As the allure of moonshine remains timeless, one question lingers: What extraordinary concoction will you craft in your own clandestine distillery?