Types of Yeast for Moonshine: 4 Commonly Used By Moonshiners

Key Takeaways

- Baker’s yeast offers decent flavor preservation in moonshine but has lower alcohol tolerance compared to specialized yeasts

- Champagne yeast produces clean, neutral spirits ideal for vodka-style moonshine with up to 18% ABV potential

- Purpose-built distiller’s yeast provides the highest alcohol yields (up to 20% ABV) while maintaining good flavor characteristics

- Turbo yeast completes fermentation in 24-48 hours but often sacrifices flavor quality for speed

- Proper yeast selection should match your base ingredients, desired flavor profile, and fermentation conditions

The yeast you choose for your moonshine isn’t just another ingredient—it’s the living engine that transforms your carefully prepared mash into alcohol. Each type brings distinct characteristics that will significantly influence your final product’s flavor, strength, and overall quality. While commercial distilleries might have specialized strains, home distillers typically work with four common types that offer reliable results.

Must-Know Facts About Moonshine Yeasts

Yeast does far more than simply produce alcohol. These microscopic fungi metabolize sugars and create various compounds that contribute significantly to your moonshine’s character. Different strains operate at varying temperature ranges, tolerate different alcohol levels, and produce unique flavor profiles. Understanding these differences can help you create a spirit that matches your preferences rather than leaving your results to chance.

When selecting yeast, you’ll need to consider factors like fermentation speed, alcohol tolerance, nutrient requirements, and flavor contribution. Some yeasts work efficiently but strip away desirable flavors, while others preserve more character but might work more slowly. This balance between efficiency and flavor is at the heart of yeast selection for quality moonshine production.

The Truth About Yeast Selection for Moonshine

“Moonshiner’s Turbo Pure Yeast – 112g …” from moonshinedistiller.com and used with no modifications.

Commercial distilleries often maintain proprietary yeast strains, carefully protected and cultivated over generations. These specialized cultures contribute to the signature character of established brands. As a home distiller, you might not have access to these exclusive strains, but that doesn’t mean you can’t produce excellent moonshine. The readily available yeasts discussed here can produce exceptional results when used correctly. For more insights into moonshining, explore the moonshining traditions that have shaped this craft over the years.

Many new distillers fall into the trap of prioritizing alcohol yield above all else. While high alcohol content is certainly desirable, focusing solely on this metric often leads to harsh, characterless spirits. The best moonshine balances potency with flavor complexity, which comes partly from the yeast’s metabolic byproducts during fermentation. For those looking to explore different yeast options, this moonshine yeast review provides valuable insights.

Temperature control during fermentation is perhaps even more important than yeast selection itself. Even the best yeast strain will produce off-flavors if fermented outside its optimal temperature range. Most moonshine yeasts perform best between 70-80°F (21-27°C), though specific ranges vary by strain. Maintaining proper temperature will maximize your chosen yeast’s potential.

Baker’s Yeast: The Readily Available Option

“Premium Yeast for Baking Bread …” from www.amazon.com and used with no modifications.

Found in nearly every grocery store, baker’s yeast (Saccharomyces cerevisiae) represents the most accessible option for moonshine production. Contrary to popular belief, experiments have shown that common bread yeast can produce respectable alcohol levels while preserving more of the natural mash flavors than some specialized strains. This makes it particularly suitable for grain-based moonshine recipes where you want to retain the character of your base ingredients.

Baker’s yeast typically comes in dry active form, requiring rehydration before pitching into your mash. For best results, rehydrate in warm (not hot) water for 15 minutes before adding to your cooled mash. This simple step significantly improves fermentation performance and reduces stress on the yeast cells. If you’re curious about how long you should let your moonshine sit, check out why moonshine has to sit for optimal results.

Flavor Profile and Alcohol Tolerance

Baker’s yeast tends to produce a fuller-bodied spirit with noticeable grain character. In comparative tastings, moonshine made with baker’s yeast often displays more complex flavor profiles compared to highly efficient but sometimes sterile-tasting specialized yeasts. This characteristic makes it well-suited for traditional corn whiskey recipes where maintaining corn flavor is desirable. For more insights, you can check out the best yeasts for distilling.

The main limitation of baker’s yeast is its relatively modest alcohol tolerance, typically maxing out around 8-10% ABV. This means your mash will contain less alcohol before distillation compared to specialized yeasts. However, since you’ll be concentrating this alcohol through distillation anyway, the lower tolerance isn’t necessarily a significant disadvantage for moonshine production.

Baker’s yeast also produces more congeners—flavor compounds that contribute both character and potential harshness. These require careful cuts during distillation to separate the desirable flavors from unwanted compounds that can cause headaches or unpleasant taste.

Best Uses in Moonshine Production

Baker’s yeast shines in traditional corn whiskey recipes and fruit-based moonshine where preserving the base ingredient’s character is important. Its ability to maintain flavor complexity makes it ideal for crafting spirits with distinct personality rather than neutral character. Many traditional moonshiners continue to use baker’s yeast precisely because it creates a product with recognizable heritage character.

For small-batch experimentation, baker’s yeast offers an affordable way to test recipes without investing in specialized distilling yeasts. Its widespread availability also makes it the perfect backup option when you can’t source distiller’s yeast but don’t want to delay starting a batch.

Baker’s Yeast Quick Reference

Alcohol Tolerance: 8-10% ABV

Fermentation Time: 4-7 days

Optimal Temperature: 70-80°F (21-27°C)

Best For: Flavor-forward traditional moonshine styles

Cost: $ (Least expensive option)

Limitations to Consider

Despite its availability and decent performance, baker’s yeast isn’t without drawbacks. Its lower alcohol tolerance means you’ll extract less alcohol from a given amount of fermentable sugars compared to specialized distiller’s yeasts. This inefficiency can be particularly problematic when working with high-sugar mashes where maximizing alcohol yield is important.

Baker’s yeast also produces more foam during vigorous fermentation, potentially creating overflow issues if your fermentation vessel lacks adequate headspace. Allow at least 25% additional headspace when using baker’s yeast compared to other varieties. Additionally, this yeast tends to produce more sulfur compounds during fermentation, which require proper aging and careful distillation cuts to eliminate from the final product.

Champagne Yeast: The Clean Fermenter

“Fruit Mash and Sugar Wash …” from learntomoonshine.com and used with no modifications.

Champagne yeast (usually Saccharomyces bayanus) has become increasingly popular among moonshiners seeking cleaner, more neutral spirits. Originally developed for sparkling wine production, this yeast’s ability to ferment at cooler temperatures and tolerate higher alcohol levels makes it exceptionally versatile for distilling purposes. Its hallmark characteristic is producing minimal congeners, resulting in spirits with less harsh fusel alcohols.

Most champagne yeasts can be purchased at homebrew supply stores in both dry and liquid forms. While slightly more expensive than baker’s yeast, the improved performance and higher alcohol yield often justify the additional cost. Popular brands include Lalvin EC-1118, Red Star Premier Blanc, and White Labs WLP715, all of which have proven reliable for moonshine production.

Why Distillers Choose Champagne Yeast

Champagne yeast’s primary advantage is its impressive alcohol tolerance, typically between 14-18% ABV. This higher tolerance means more complete fermentation and greater alcohol yields from your mash. For sugar-heavy washes especially, champagne yeast can extract significantly more alcohol than baker’s yeast before becoming inhibited.

Another major advantage is this yeast’s ability to ferment cleanly at lower temperatures (55-75°F/13-24°C). This cooler fermentation reduces the production of fusel alcohols and other harsh compounds that can negatively impact your moonshine’s smoothness. The result is a cleaner distillate requiring less aging to become palatable.

Champagne yeast also has excellent flocculation characteristics, meaning it settles well after fermentation is complete. This property makes it easier to separate the liquid from the yeast sediment before distilling, resulting in a cleaner wash that produces less scorching in your still.

Ideal Mash Types for Champagne Yeast

Champagne yeast excels with sugar washes and fruit-based mashes where a neutral fermentation profile is desired. Its ability to ferment cleanly without contributing strong yeast-derived flavors makes it perfect for vodka-style moonshine or as a base for flavored spirits where you want the added ingredients (not yeast character) to dominate.

For those making spirit runs intended for aging with oak or other flavor additions, champagne yeast provides a clean canvas that readily accepts these influences. The minimal congener profile allows added flavoring elements to shine through without competing with yeast-derived compounds.

Temperature Range and Fermentation Speed

One of champagne yeast’s most valuable characteristics is its wide temperature tolerance. While most yeasts perform best within a narrow range, champagne yeast remains viable from 50°F to 86°F (10°C to 30°C), with optimal performance between 59°F and 75°F (15°C and 24°C). This flexibility makes it well-suited for home environments where precise temperature control might be challenging.

Fermentation with champagne yeast typically completes within 7-14 days, depending on temperature, nutrient availability, and sugar content. While not as rapid as turbo yeast, it strikes an excellent balance between speed and quality. The fermentation profile tends to be steady and predictable, starting quickly and proceeding at a consistent rate until completion.

Unlike some aggressive yeasts that can create excessive heat during fermentation, champagne yeast maintains a more moderate metabolic rate, reducing the risk of temperature spikes that can create off-flavors. This self-regulating quality makes it forgiving for beginners still mastering temperature control.

Expected Alcohol Yield

When properly pitched into a sugar-rich mash with adequate nutrients, champagne yeast consistently achieves alcohol levels of 14-18% ABV. This high alcohol tolerance makes it approximately twice as efficient as baker’s yeast in converting available sugars to alcohol. For a 5-gallon sugar wash with appropriate nutrients, expect approximately 50% more alcohol yield compared to baker’s yeast.

The clean fermentation profile translates to more efficient distillation runs with better separation between foreshots, heads, hearts, and tails. This cleaner division allows you to collect a higher percentage of the total alcohol as quality hearts, improving your overall yield of drinkable spirits from each batch.

Distiller’s Yeast: Purpose-Built for Spirits

“High Spirits Whisky Distillers Yeast …” from www.essentialdistilling.com and used with no modifications.

Specialized distiller’s yeasts represent the gold standard for serious moonshine production. These strains have been specifically developed to maximize alcohol production while maintaining desirable flavor characteristics. Unlike baker’s or wine yeasts, which were developed for other purposes, distiller’s yeast has been selectively bred to thrive in the high-sugar, high-alcohol environment of moonshine mash.

Most distiller’s yeasts are highly robust, stress-tolerant strains capable of fermenting a wide variety of sugars efficiently. They typically contain added nutrients and often incorporate multiple yeast strains working in harmony to optimize both fermentation performance and flavor development. While more expensive than other options, many experienced moonshiners consider them well worth the investment.

Super Start and Other Popular Brands

Super Start has become one of the most widely recognized brands in home distilling circles, known for its consistent performance and balanced approach to alcohol yield versus flavor development. This strain typically achieves 15-18% ABV while maintaining desirable grain character in the final spirit. It performs especially well with corn, rye, and mixed grain mashes intended for whiskey-style moonshine.

Other popular distiller’s yeast brands include Prestige, Still spirits, and DADY (Distiller’s Active Dry Yeast). Each offers slightly different characteristics, with some optimized for maximum alcohol production and others designed to enhance specific flavor profiles. Most come with detailed instructions for rehydration and pitching rates, making them user-friendly even for beginners.

Flavor Contributions to Final Product

Distiller’s yeasts are engineered to produce balanced flavor compounds that complement rather than overpower the character of your base ingredients. They typically create moderate esters that contribute pleasant fruity notes without overwhelming the grain or fruit character. This balanced approach results in spirits that maintain their connection to the original ingredients while still offering complexity and depth.

When used with corn mashes, quality distiller’s yeast helps develop the sweet, creamy notes characteristic of traditional moonshine. For fruit-based spirits, these yeasts enhance the natural fruit flavors while adding subtle complexity. This harmony between base ingredients and yeast-derived flavors is what separates premium moonshine from harsh, one-dimensional spirits.

Alcohol Tolerance and Efficiency

Purpose-built distiller’s yeasts boast impressive alcohol tolerances, typically ranging from 18-20% ABV. This high tolerance allows for more complete sugar conversion, maximizing the alcohol yield from your mash. Most strains can ferment a wide variety of sugars, including complex sugars that other yeasts might leave behind, ensuring you extract the most alcohol possible from your ingredients.

Efficiency isn’t just about alcohol production—it’s also about fermentation time and resource utilization. Quality distiller’s yeasts typically complete fermentation in 3-5 days under optimal conditions, significantly faster than baker’s or champagne yeast without sacrificing quality. This efficiency extends to nutrient utilization, requiring less additional nutrient supplementation than other yeasts to achieve complete fermentation.

Turbo Yeast: The Fast and Furious Option

“Still Spirits FAST Turbo Yeast Express …” from www.hobbyhomebrew.com and used with no modifications.

Turbo yeast represents the most aggressive option available to moonshiners, designed to ferment extremely rapidly and tolerate very high alcohol levels. These specialized formulations combine multiple yeast strains with extensive nutrient packages and often include additional enzymes to break down complex sugars. The result is a product that can ferment a sugar wash to 14-20% ABV in just 24-48 hours—a fraction of the time required by other yeasts.

This remarkable speed comes from the comprehensive nutrient package included in turbo yeast formulations. These typically contain nitrogen sources, vitamins, minerals, and buffers that maintain optimal conditions for the yeasts even as alcohol levels rise rapidly. Some formulas even include carbon for filtering out congeners during fermentation.

Speed vs. Quality Considerations

The primary appeal of turbo yeast is unquestionably its speed. Being able to complete fermentation in 1-2 days rather than 1-2 weeks represents a significant advantage for production-focused distillers. This rapid turnaround allows for more frequent distillation runs and quicker production cycles, potentially increasing overall output.

However, this speed comes at a cost to quality. The aggressive fermentation produces higher levels of fusel alcohols and other harsh compounds that can create a “hot” sensation and contribute to hangovers. The rapid gas production can also strip away desirable flavor compounds, resulting in a relatively neutral but often harsh spirit. Most experienced moonshiners agree that turbo yeast sacrifices flavor complexity for speed.

Additionally, the very rapid fermentation generates significant heat, requiring careful temperature management to prevent the mash from overheating. Without proper cooling, temperatures can easily exceed the yeast’s tolerance range, potentially causing stuck fermentation or off-flavors.

When Turbo Yeast Makes Sense

Despite its drawbacks, turbo yeast does have legitimate applications in moonshine production. It’s particularly useful for creating neutral base spirits intended for flavored products where the original character will be masked anyway. For creating vodka-style spirits that will undergo multiple distillations and carbon filtering, the flavor limitations become less relevant.

Turbo yeast also makes sense when production speed is the primary concern. For commercial or semi-commercial operations where time equals money, the ability to complete fermentation in 24-48 hours represents a significant advantage. This rapid turnaround can be especially valuable when producing spirits to meet seasonal demand spikes.

For beginners eager to see quick results, turbo yeast provides nearly immediate gratification. However, most experienced distillers recommend moving beyond turbo yeast as you develop your skills and appreciation for quality spirits.

Common Problems and Solutions

The most frequent issue with turbo yeast is excessive foam production during the vigorous fermentation. This foam can easily overflow your fermentation vessel if adequate headspace isn’t provided. To prevent this problem, either use a fermenter with at least 30% headspace or add a few drops of food-grade antifoam agent to control excessive foaming.

Heat management represents another significant challenge. The rapid fermentation generates substantial heat that can stress or even kill the yeast if not controlled. Using a water bath or wet towel wrap around your fermenter can help dissipate excess heat. For larger batches, consider dedicated cooling systems or fermenting in a temperature-controlled environment.

The harsh flavors associated with turbo yeast can be partially mitigated through proper distillation technique. Making more conservative cuts—taking only the purest portion of the hearts—helps eliminate many undesirable compounds. Multiple distillations and carbon filtering can further improve the final product, though these steps add time back into the process. For more insights on how to enhance your brew, check out this guide on making moonshine taste smooth.

How to Choose the Right Yeast for Your Moonshine

“The Best Yeast for Distilling and Brewing” from www.clawhammersupply.com and used with no modifications.

Selecting the appropriate yeast for your moonshine ultimately depends on balancing several factors: your desired flavor profile, production timeline, available equipment, and overall goals. There’s no single “best” yeast for all situations—each has strengths and weaknesses that make it more suitable for specific applications.

Consider your priorities carefully. Are you looking to produce a traditional, flavor-forward moonshine that showcases the character of your ingredients? Or do you need a neutral base for creating flavored spirits? Is maximum alcohol yield your primary concern, or are you willing to sacrifice some efficiency for better flavor? Your answers to these questions will guide your yeast selection.

Matching Yeast to Your Base Ingredients

For corn-based traditional moonshine, baker’s yeast or specialized distiller’s yeast typically provides the best results, preserving the sweet, creamy corn character while adding complexity. The moderate fermentation rate allows flavor compounds to develop fully, creating a spirit with authentic character and depth. To delve deeper into the process, explore more about moonshining traditions that influence these choices.

Fruit mashes benefit from champagne yeast’s clean profile, which allows the natural fruit flavors to shine through without competing yeast notes. This is especially important for delicate fruits like berries or peaches, where subtle aromatics can easily be overwhelmed by aggressive yeast characteristics. For more information on choosing the best yeast, check out this guide on the best yeasts for distilling.

For simple sugar washes intended to produce neutral spirits, turbo yeast or champagne yeast offers the most efficient conversion. Since flavor preservation isn’t a primary concern with neutral spirits, the higher alcohol yields and faster fermentation times of these yeasts become more valuable.

Temperature Considerations

Your ability to control fermentation temperature should significantly influence your yeast selection. If you’re fermenting in an environment with fluctuating temperatures or limited climate control, champagne yeast’s wide temperature tolerance makes it the most forgiving option. It can produce acceptable results even when temperatures vary by 10-15°F throughout fermentation.

For those with more precise temperature control, distiller’s yeast typically offers the best balance of flavor and efficiency when kept in its optimal range (usually 75-85°F/24-29°C). However, this narrower optimal range means it’s more sensitive to temperature fluctuations.

Turbo yeast generates significant heat during fermentation and generally requires active cooling to maintain appropriate temperatures. Without the ability to dissipate this heat, fermentation can easily exceed 90°F/32°C, creating excessive fusel alcohols and potentially stressing the yeast to the point of stalling.

Flavor Goals and Yeast Selection

For full-flavored traditional moonshine with authentic character, baker’s yeast or specialty distiller’s yeast provides the best results. These yeasts preserve more of the grain or fruit character while adding complementary complexity. The tradeoff is slightly lower alcohol yield and longer fermentation times.

When aiming for a clean, neutral spirit, champagne yeast offers an excellent balance of efficiency and quality. Its minimal flavor impact and high alcohol tolerance make it ideal for producing spirits that will serve as a blank canvas for other flavors or extensive aging.

If maximum alcohol yield is your primary goal regardless of flavor impact, turbo yeast delivers the highest conversion efficiency. Just be prepared to implement more extensive filtering, multiple distillations, or flavor additions to compensate for the potential harshness.

Cost vs. Quality Analysis

While specialized distiller’s yeasts cost more than common baker’s yeast, the improved performance often justifies the investment. A single packet of quality distiller’s yeast (typically $3-8) can ferment 5-6 gallons of mash to a higher alcohol level with better flavor than baker’s yeast, potentially yielding an additional 15-20% more finished product per batch.

Turbo yeast represents the highest initial cost (often $8-15 per packet), but its rapid fermentation can increase production capacity significantly. For those producing larger volumes, this increased throughput may offset the higher yeast cost. However, the potential quality limitations should be carefully considered.

For hobbyists making occasional small batches, baker’s yeast offers the most economical option without requiring special ordering or storage considerations. While it may produce slightly less alcohol, the flavor quality often compensates for this limitation, especially for traditional style moonshine.

Proper Yeast Handling for Maximum Results

“1kg Liquor Quik Super Yeast X-Press …” from moonshinedistiller.com and used with no modifications.

No matter which yeast you select, proper handling significantly impacts performance and final quality. Even the best yeast strain will underperform if mishandled, while careful attention to rehydration, pitching, and fermentation conditions can elevate even basic yeasts to produce excellent results. For a detailed review of different yeast strains, check out this moonshine yeast review. The care you take during these initial steps sets the foundation for your entire batch.

Rehydration Techniques

Dry yeasts benefit enormously from proper rehydration before pitching into your mash. Rather than sprinkling yeast directly onto your cooled mash, take a few minutes to rehydrate it in warm water first. This simple step dramatically improves viability and reduces lag time before active fermentation begins.

For most distiller’s yeasts, rehydrate in water between 95-105°F (35-40°C) for 15-20 minutes. Use approximately 10 times the weight of yeast in water—typically about 1 cup of water per packet. Avoid using chlorinated tap water, as chlorine can damage yeast cells. After rehydration, allow the temperature to equalize with your mash before pitching to prevent thermal shock.

Pitching Rates for Different Mash Types

The amount of yeast needed varies based on your mash type and starting gravity. For standard grain mashes, one packet (typically 5-10 grams) per 5 gallons provides adequate cell counts for healthy fermentation. Sugar washes benefit from slightly higher pitching rates—approximately 1.5 packets per 5 gallons—as they lack many of the natural nutrients found in grain mashes.

High-gravity mashes (those with very high sugar content) require even higher pitching rates to ensure the yeast population can handle the challenging environment. For starting gravities above 1.080, consider doubling the standard pitching rate to prevent stressed fermentation that could produce excess fusel alcohols and off-flavors.

When using baker’s yeast, which typically comes in smaller packages, use approximately 1.5-2 tablespoons per 5-gallon batch. This higher volume compensates for the fact that baker’s yeast contains fewer viable cells per gram than specialized distiller’s yeasts.

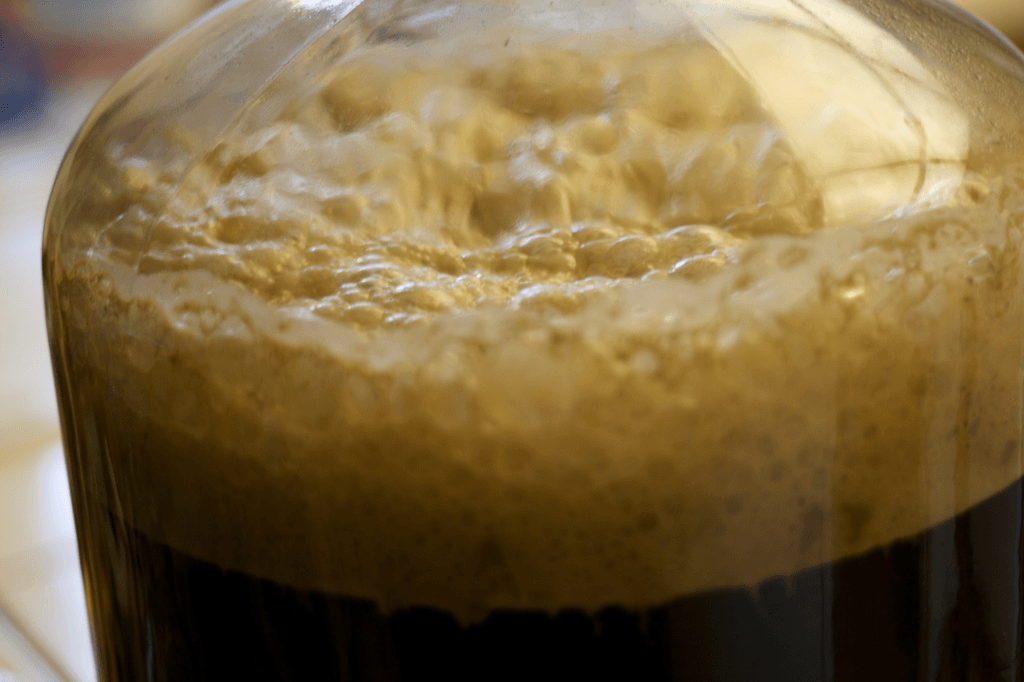

Signs of Healthy Fermentation

Proper fermentation typically begins with visible activity within 12-24 hours, depending on yeast type and temperature. Look for foam formation, bubbling through your airlock, and a noticeable drop in specific gravity as measured with a hydrometer. The most active period usually occurs between 24-72 hours after pitching, with activity gradually slowing as sugars are consumed.

Healthy fermentation should smell yeasty with fruity or bready notes—never strongly sulfurous or vinegar-like. If you detect strong rotten egg smells, your yeast may be stressed due to nutrient deficiencies or temperature issues. Adding yeast nutrient mid-fermentation can sometimes help recover troubled batches.

Fermentation is complete when specific gravity readings remain stable for two consecutive days and have reached terminal gravity appropriate for your yeast strain. For most distiller’s yeasts, this means reaching 1.000 or slightly below. At this point, the liquid should be relatively clear with yeast settling to the bottom, and airlock activity should have nearly ceased.

The Bottom Line on Moonshine Yeasts

“Moonshine… | mrs elliott” from mrselliott.wordpress.com and used with no modifications.

The best yeast for your moonshine depends on your specific goals, equipment, and preferences. Baker’s yeast offers accessibility and good flavor preservation, champagne yeast provides clean efficiency, dedicated distiller’s yeasts balance quality with performance, and turbo yeast maximizes speed at some cost to flavor quality. By understanding these differences, you can make informed choices that align with your moonshine-making objectives.

Regardless of which yeast you choose, proper handling techniques and attention to fermentation conditions will significantly impact your results. Even the most basic yeast can produce excellent moonshine when used correctly, while the most sophisticated strains will disappoint if mishandled. Experiment with different options to discover which works best for your specific recipes and production methods.

Frequently Asked Questions

After exploring the main yeast options for moonshine production, several common questions tend to arise. These practical considerations can help refine your process and improve your results, especially as you gain experience and look to advance your distilling skills.

Many of these questions reflect the hands-on nature of moonshine production, where practical knowledge often proves as valuable as theoretical understanding. The answers below represent consensus among experienced home distillers and have been validated through practical application.

Can I reuse yeast from a previous batch of moonshine?

Yes, you can reuse yeast from previous batches through a process called “washing” or “harvesting.” After fermentation completes, collect the yeast sediment from the bottom of your fermenter, rinse it with boiled and cooled water to remove alcohol and residual solids, then store it in sanitized containers in your refrigerator. This harvested yeast can be used to start new batches, often with improved performance as the yeast has already adapted to your specific fermentation conditions.

Reused yeast typically shows faster startup times and sometimes develops enhanced flavor characteristics as it adapts to your specific ingredients and environment. However, after 3-5 generations, the yeast may begin to show signs of genetic drift or contamination, so it’s advisable to start fresh periodically.

For optimal results when reusing yeast, use a larger amount of harvested slurry than you would dry yeast—approximately 1-2 cups of thick slurry per 5 gallons of mash. This compensates for some inevitable cell death during storage and handling.

Yeast Washing Process

1. Allow yeast to settle after fermentation completes

2. Siphon off most of the liquid, leaving yeast sediment

3. Add boiled and cooled water, stir gently, and let settle again

4. Repeat washing process 2-3 times until liquid above yeast is clear

5. Store thick slurry in sanitized jar in refrigerator for up to 2 weeks

How much yeast should I add to a 5-gallon mash?

For a standard 5-gallon grain or fruit mash, use one packet (usually 5-11 grams) of distiller’s yeast, approximately two packets of champagne yeast, or about 1.5-2 tablespoons of baker’s yeast. Higher-gravity mashes benefit from increased pitching rates—consider using 50-100% more yeast when your starting gravity exceeds 1.080. Remember that underpitching (using too little yeast) typically causes more problems than overpitching, including extended lag times, increased risk of contamination, and higher production of fusel alcohols that can create harsh flavors.

Will different yeasts affect the final proof of my moonshine?

Different yeasts will affect the potential alcohol content in your fermented mash, but not the final proof of your distilled moonshine. The maximum ABV in your mash depends on your yeast’s alcohol tolerance (ranging from about 8-20% depending on yeast type), but distillation can concentrate this alcohol to much higher levels regardless of which yeast you used. The final proof is determined primarily by your distillation technique and equipment, not your yeast selection. However, yeasts with higher alcohol tolerance will produce more total alcohol in your mash, potentially increasing your overall yield of finished moonshine per batch.

What’s the shelf life of unopened distiller’s yeast?

Properly stored, unopened packets of dry distiller’s yeast typically remain viable for 1-2 years past their production date. Store them in a cool, dry place away from direct sunlight for maximum longevity. Refrigeration can extend shelf life but isn’t necessary for unopened packets. If you’re uncertain about old yeast, you can test viability by rehydrating a small amount in warm sugar water—active yeast should show foaming and bubble formation within 10-15 minutes.

Can I mix different types of yeast in the same batch?

Yes, combining yeasts can create interesting flavor profiles and improved performance. Some distillers intentionally blend baker’s yeast for flavor with champagne or distiller’s yeast for alcohol tolerance. When mixing yeasts, add them simultaneously rather than sequentially for best results. Common combinations include 25% baker’s yeast with 75% distiller’s yeast to balance flavor development with alcohol production, or equal parts champagne yeast and distiller’s yeast to combine clean fermentation with enhanced flavor complexity.

Experimentation is key to finding the perfect combination for your specific recipes and preferences. Keep detailed notes on your blends and results to refine your approach over time. Many professional distilleries maintain proprietary yeast blends that contribute to their distinctive house character.

Remember that yeast selection is just one factor in crafting quality moonshine. Equally important are your ingredient selection, mash preparation, fermentation conditions, and distillation technique. Each element contributes to the character and quality of your final product.

For the best results, take time to understand how different yeasts interact with your specific ingredients and equipment setup. This knowledge will allow you to make informed choices that consistently produce moonshine tailored to your preferences. For more insights, you can check out this moonshine yeast review.

For more tips on perfecting your moonshine recipes and techniques, visit Clawhammer Supply, where experienced distillers share insights gained from years of hands-on experience with various yeast strains and distilling methods.

Moonshining is a time-honored tradition that has been passed down through generations. Many moonshiners experiment with different ingredients to create unique flavors. For those interested in exploring new tastes, there are various infused moonshine recipes that can be tried. These recipes often include fruits, herbs, and spices, allowing for a personalized touch to the classic moonshine experience.