What Are the Dangers of Home Distilling: Safety Concerns Every Distiller Should Know

Key Takeaways

- Home distilling presents significant fire and explosion hazards due to the highly flammable nature of alcohol vapors, requiring proper ventilation and fire safety measures.

- Methanol poisoning is a real danger in home distillation, potentially causing blindness or death if proper techniques aren’t followed to separate and discard toxic foreshots.

- Home distillation without proper permits is illegal in the United States, carrying potential felony charges, heavy fines, and even imprisonment.

- Improper equipment or setup can lead to dangerous equipment failures including pressure buildups, explosions, and severe burns from hot metal and steam.

- Carbon monoxide poisoning from inadequate ventilation represents a silent but deadly risk when using fuel-burning heat sources for distillation.

The art of distillation carries inherent dangers that every home distiller must understand before embarking on this craft. While the allure of creating your own spirits might be strong, the risks involved demand proper knowledge, equipment, and precautions. The difference between a rewarding hobby and a disastrous outcome often comes down to understanding and respecting these dangers.

Having the right information about distillation safety isn’t just helpful—it’s essential. Whiskey Still Pro, a leading authority on home distillation education, emphasizes that proper safety protocols are non-negotiable for anyone interested in learning about this traditional craft. Their comprehensive resources help enthusiasts understand the science and safety behind distillation, ensuring that education always comes first.

Fire and Explosion Hazards When Distilling at Home

“Explosion PNG Images, Download 10000+ …” from pngtree.com and used with no modifications.

Fire represents the single most immediate danger in home distilling operations. The distillation process combines three elements of the fire triangle—heat sources, flammable alcohol vapors, and oxygen—creating an environment where one small mistake can lead to devastating consequences. Commercial distilleries implement rigorous safety protocols and equipment for precisely this reason.

A typical home distillation setup contains multiple fire hazards that require constant attention. Heat sources used to warm the wash, alcohol vapors that can escape from leaky connections, and collection vessels containing high-proof spirits all present significant ignition risks. Without proper precautions, a minor equipment malfunction or momentary lapse in attention can quickly escalate into an emergency situation.

Why Alcohol Vapors Are Highly Flammable

Alcohol vapors represent a greater danger than liquid alcohol because they mix readily with air to form explosive compounds. When distilling, ethanol vaporizes at approximately 173°F (78.5°C), creating invisible, highly flammable vapor clouds that can travel surprising distances from the still. These vapors are significantly more dangerous than liquid ethanol because they can ignite with minimal heat or spark sources.

The lower explosive limit (LEL) for ethanol vapor in air is just 3.3% by volume, meaning that even small leaks in your distillation system can create explosive conditions. What makes this particularly dangerous is that these vapors are heavier than air and will flow downward, potentially reaching distant ignition sources like pilot lights, electrical switches, or heating elements that you might not consider threats.

During distillation, vapor concentrations inside the still and condensation pathways frequently exceed this explosive threshold by many times. This explains why commercial distilleries implement elaborate safety systems including explosion-proof electrical components, sophisticated ventilation, and rigorous maintenance schedules.

Common Ignition Sources in Distilling Environments

The distilling environment contains numerous potential ignition sources that must be carefully managed. Open flames from gas burners present the most obvious danger, but many distillers underestimate other heat sources. Electric heating elements, which can reach temperatures well above alcohol’s ignition point, pose similar risks despite lacking visible flames. For more insights on maintaining safety, consider these safety tips for moonshiners.

Less obvious ignition risks include electrical sparks from switches, thermostats, or motors, static electricity discharges from clothing or movement, hot surfaces like exhaust pipes or heating elements, and even friction sparks from metal tools. Any of these can provide the minimum ignition energy needed to trigger a vapor explosion—which requires surprisingly little energy when conditions are right. For more information on the components involved, explore the main parts of a still.

Proper distillation safety requires eliminating or controlling these ignition sources through careful equipment selection, proper electrical grounding, explosion-proof components when possible, and maintaining adequate separation between heating elements and areas where vapors might accumulate. Even smartphone use near an operating still presents risks many home distillers overlook.

Fire Safety Checklist for Home Distillers

- Keep ABC fire extinguisher within arm’s reach

- Maintain 10′ minimum distance between still and heat source

- Eliminate all ignition sources from distillation area

- Check all connections for leaks before each run

- Never leave a running still unattended

- Use electric heating when possible instead of open flame

- Install vapor-proof lighting and switches

- Ensure proper ventilation at all times

Real-Life Accidents: What Went Wrong

The history of home distilling includes sobering examples of safety failures. In a documented case from 2018, a home distiller in rural Tennessee experienced a devastating garage fire after vapors from a leaky still reached a water heater pilot light approximately 15 feet away. Despite having a fire extinguisher present, the rapidly spreading fire consumed the structure before emergency responders could arrive. Fortunately, the operator escaped with minor burns, but the financial and property losses were significant.

Another incident involved a distiller who attempted to adjust still components during operation without proper cooling. The sudden release of pressurized alcohol vapor created a vapor cloud that ignited on contact with the heating element, causing severe facial and upper body burns. These cases illustrate that even experienced operators can face life-threatening consequences when proper procedures aren’t followed rigorously.

Methanol Poisoning: The Silent Killer

“4+ Hundred Methanol Poisoning Royalty …” from www.shutterstock.com and used with no modifications.

Beyond the immediate dangers of fire, methanol poisoning represents one of the most serious health risks associated with improperly produced spirits. Unlike ethanol, which causes typical alcohol intoxication, methanol metabolizes in the body to formaldehyde and formic acid—compounds highly toxic to the central nervous system and specifically damaging to the optic nerve. This explains the historical association between bootleg spirits and blindness. For more information on safety, consider these important safety tips for moonshiners.

Methanol poisoning is particularly dangerous because initial symptoms resemble ordinary alcohol intoxication, often delaying proper medical intervention until significant damage has occurred. Just 10mL of pure methanol can cause permanent blindness, and as little as 30mL can be lethal. The risk is magnified by methanol’s tendency to concentrate in the early fractions of distillation runs, creating potentially dangerous levels in improperly managed distillate. For those interested in learning more about safe practices, here are important safety tips for moonshiners.

How Methanol Forms During Fermentation

Methanol occurs naturally during fermentation when pectins in certain fruits, vegetables, and grains break down. While fermentation primarily produces ethanol, small amounts of methanol are generated as a byproduct, especially when fermenting fruits with high pectin content such as apples, pears, and plums. The amount of methanol produced varies significantly based on fermentation ingredients, with grain-based washes typically producing less methanol than fruit-based washes.

During distillation, methanol becomes concentrated in the early portion of the distillate due to its lower boiling point (148.5°F/64.7°C) compared to ethanol (173.1°F/78.4°C). This concentration effect means that even fermentation mash with relatively safe methanol levels can produce dangerous concentrations in the first portions collected during distillation—commonly called “foreshots” or early “heads.” For more information on safety practices, consider these safety tips for moonshiners.

Commercial distilleries use precise temperature control, specialized equipment, and scientific testing to manage methanol risks. They also benefit from larger batch sizes which dilute methanol concentration and make separation more predictable. Home distillers working with smaller volumes face greater challenges in separating dangerous compounds and must be especially vigilant about discarding early distillate fractions.

Symptoms of Methanol Toxicity

Methanol poisoning initially presents symptoms similar to ordinary alcohol intoxication, making early diagnosis challenging. Within 12-24 hours of consumption, victims typically experience headache, dizziness, nausea, and vomiting—symptoms that might be dismissed as a typical hangover. This delay in recognizing the true problem contributes significantly to methanol’s danger.

As methanol metabolizes into toxic compounds, more serious symptoms develop including central nervous system depression, difficulty breathing, blurred vision, blindness, seizures, and potentially coma or death. The signature symptom—vision disturbance—occurs because formic acid produced during methanol metabolism specifically damages the optic nerve. Unfortunately, by the time vision symptoms appear, damage is often permanent.

Medical treatment for methanol poisoning requires hospital intervention with antidotes (typically ethanol or fomepizole) that block methanol metabolism, plus hemodialysis to remove the toxin from the bloodstream. Without prompt treatment, severe poisoning frequently results in permanent disability or death, highlighting why proper distillation technique is literally a matter of life and death.

The “Foreshots” Myth vs. Reality

A dangerous myth persists among some home distillers that simply discarding a fixed percentage or volume of the initial distillate guarantees safety. While discarding foreshots and early heads fractions is essential, the actual volume requiring removal varies based on many factors including fermentation ingredients, batch size, still design, and distillation technique. No universal “rule of thumb” can ensure safety across different distillation scenarios.

Another concerning misconception is that you can “smell” or taste methanol to determine when the dangerous portion has passed. In reality, methanol has little odor and a mildly sweet taste similar to ethanol, making sensory detection unreliable. Commercial distillers rely on precise temperature monitoring, specific gravity measurements, and laboratory testing rather than sensory evaluation to ensure safety.

The scientific reality is that proper methanol management requires understanding the chemistry involved, proper equipment, careful temperature monitoring, and conservative discarding practices. When human health is at stake, distillers must err on the side of caution rather than efficiency or yield. For those interested in the components of distillation equipment, understanding the three main parts of a still is essential.

Proper Discarding of the Heads to Prevent Poisoning

Safe distillation requires systematically separating and discarding the foreshots and early heads fractions where methanol concentrates. Professional distillers typically discard the first 100-150ml per 20 liters of wash (approximately 5-7.5ml per liter), though this varies based on the ingredients fermented and other factors. This conservative approach prioritizes safety over yield—a practice home distillers should always follow.

Beyond the initial foreshots, the heads fraction contains diminishing methanol levels along with other volatile compounds that may cause discomfort (including acetone, acetaldehyde, and various esters). Many experienced distillers discard roughly the first 20-30% of the theoretical yield to ensure both safety and quality, though exact percentages depend on equipment and input materials.

The safest approach combines temperature monitoring, small collection vessels to enable precise fraction separation, and a conservative discarding policy. Remember that no home test can reliably detect methanol in your distillate—the only guaranteed safety measure is proper technique and generous discarding of early fractions. For more insights, consider these safety tips for moonshiners.

Legal Consequences of Illegal Distilling

“Guide to Home Distilling – InsideHook” from www.insidehook.com and used with no modifications.

Home distillation without proper permits remains illegal throughout the United States, regardless of state-level alcohol laws or personal property considerations. This prohibition stems from both taxation concerns and public safety regulations implemented after numerous poisoning incidents during Prohibition. The federal government takes these violations seriously, with enforcement handled primarily through the Alcohol and Tobacco Tax and Trade Bureau (TTB) and sometimes involving other agencies like the ATF.

Many home distillers incorrectly believe that small-scale production “for personal use” falls under a legal exception similar to homebrewing beer or making wine. This is absolutely false. While federal law allows adults to produce limited quantities of beer and wine for personal use, no such exception exists for distilled spirits at any volume. Penalties for illegal distillation can include felony charges, substantial fines, and imprisonment regardless of production scale.

Federal Laws Against Home Distilling

Federal law prohibits distilling spirits without specific permits under two separate legal frameworks. Tax laws require a federal Distilled Spirits Plant permit, federal excise tax payments, and compliance with reporting requirements. Safety regulations separately require permits, approved facilities, and compliance with production standards. Violations of either framework can trigger serious legal consequences.

The penalties for illegal distillation include felony charges carrying up to 5 years in federal prison and/or fines up to $10,000 for producing distilled spirits, plus additional charges for evading federal excise taxes which can add substantial penalties. Even possession of an unregistered still is illegal under federal law, carrying potential imprisonment up to 5 years and/or additional fines. For those considering home distillation, it’s crucial to understand the safety tips for moonshiners to avoid legal and safety issues.

Enforcement priorities typically focus on commercial-scale operations or instances where illegal spirits enter distribution channels, but small-scale home distillers have faced prosecution, particularly after accidents, injuries, or when operating alongside other illegal activities. The law provides no protection for “educational” or “personal use” distillation without proper permits. For more information on the legality of distilling, you can read about whether stills are illegal in the US.

State-Level Penalties and Enforcement

Beyond federal regulations, many states maintain additional laws against illegal distillation with varying penalties. In traditional moonshining regions like Kentucky, Tennessee, and Virginia, state laws sometimes impose harsher penalties than federal statutes, reflecting historical concerns about unregulated spirits. Some states classify illegal distillation as a felony on first offense while others treat initial violations as misdemeanors with escalating penalties for repeat offenses.

State enforcement approaches vary significantly by region. In some areas, authorities prioritize commercial operations or those causing public safety hazards, while other jurisdictions maintain more aggressive enforcement against any illegal distillation. Local attitudes and resources influence enforcement priorities, but the underlying illegality remains constant regardless of location.

Legal Alternatives to Consider

While home distillation remains illegal, several legal alternatives exist for those interested in the craft. Fuel alcohol permits (issued through the TTB) allow individuals to distill alcohol specifically for fuel purposes, though these permits require extensive paperwork, strict reporting, and denaturing the alcohol to prevent consumption. These permits don’t provide a legal loophole for producing consumable spirits.

Another legal option is pursuing commercial distilling permits and licenses. Craft distilling has exploded in popularity, with many states offering various tiers of distillery licenses. While requirements are substantial (including dedicated facilities, significant capital investment, and regulatory compliance), this path provides a legitimate way to pursue distillation as more than a hobby.

For those primarily interested in the process rather than consumption, educational courses at legitimate distilling schools or purchasing legal non-functioning replica stills for display purposes remain fully legal. Many enthusiasts also find that learning about commercial distilling techniques through books, videos, and distillery tours satisfies their interest without legal risk.

Equipment Failures That Cause Injuries

“Defective Work Equipment Injury Claims …” from www.legalexpert.co.uk and used with no modifications.

Beyond fire and poisoning risks, mechanical failures present another category of dangers in home distillation. Pressure-related accidents occur when vapor cannot escape a heated still, causing catastrophic ruptures that spray scalding liquid and potentially ignite alcohol vapors. These failures typically result from blocked condensers, inadequate venting, or improper pressure relief systems.

Equipment quality directly impacts safety, with substandard materials or construction creating numerous hazards. Lead solder, galvanized metals, rubber gaskets, and plastic components can all introduce toxins or fail under distilling conditions. Proper distillation requires food-grade stainless steel, copper, or glass components specifically designed to withstand the temperatures, pressures, and chemical environment of alcohol distillation. For more information on still components, check out the three main parts of a still.

Pressure Build-Up and Still Explosions

Pressure accidents represent some of the most violent and dangerous distilling failures. When vapor cannot escape a heated still at the same rate it’s being created, pressure builds rapidly. Most home-built or imported hobby stills lack proper pressure relief mechanisms, creating the potential for catastrophic ruptures that spray scalding liquid and potentially create explosive vapor clouds.

Common causes of pressure buildup include blockages in condensers from flour paste used in sealing, collapsed tubing from improper support, insufficient condenser capacity for the heat input, and operator errors like closing valves that should remain open during operation. Without proper pressure gauges and relief valves, operators may have no warning before catastrophic failure occurs. For more information on the legality and safety of distilling, you can check if stills are illegal in the US.

Professional distilleries use engineered pressure vessels with proper relief systems, regular inspection protocols, and multiple redundant safety features to prevent these scenarios. Home distillers rarely implement such comprehensive safeguards, creating significant risk when operating equipment at or beyond its design limitations.

Dangerous Sealing Materials to Avoid

Material selection critically impacts both safety and product quality in distillation equipment. Many improvised stills incorporate materials that release toxins when exposed to alcohol vapors or high temperatures. Lead solder, commonly found in older plumbing and some imported stills, can leach into distillate causing cumulative lead poisoning. Galvanized metals release zinc and other contaminants when exposed to acidic wash or alcohol vapors.

Plastic components present multiple hazards in distillation systems. Most plastics degrade when exposed to alcohol (especially at elevated temperatures), releasing various compounds into the distillate. Many plastics also present fire hazards, either by melting, deforming, or potentially igniting when exposed to heat sources or hot vapors.

Rubber seals, silicone caulk, plumber’s putty, and other common sealing materials can similarly contaminate distillate with off-flavors at best and toxic compounds at worst. Proper distillation equipment uses appropriate high-temperature food-grade sealing methods including PTFE tape, copper crush gaskets, or specialized high-temperature silicone designed specifically for distillation applications.

Burns from Hot Equipment and Steam

Contact burns represent one of the most common distillation injuries, occurring when operators touch hot metal surfaces or are exposed to steam. Distillation typically operates between 173°F (78.5°C) for ethanol boiling and 212°F (100°C) for water—temperatures that cause immediate second-degree burns on contact with unprotected skin. Metal components can remain dangerously hot long after heat sources are removed, creating burn hazards throughout the distillation process and cleanup.

Steam burns are particularly dangerous because steam carries significantly more thermal energy than water at the same temperature due to its latent heat of vaporization. When steam condenses on skin, it transfers this additional energy while cooling to water, causing deeper, more severe burns than hot water at the same temperature. Leaking joints, loose connections, or operator errors when opening equipment components can all result in steam exposure.

Proper safety measures include heat-resistant gloves rated for the temperatures involved, long sleeves and pants made from natural fibers, appropriate eye protection, and careful handling procedures. Equipment should be allowed to cool completely before disassembly or cleaning, and all pressure should be verified as released before opening any component of a still.

Poor Quality Parts and Their Risks

The market for distillation equipment includes many low-quality imported products that compromise safety. Common issues include insufficient material thickness for heat distribution, poor welding quality leading to leaks or failure, inadequate cooling capacity in condensers, and improper metallurgy that introduces contamination. Budget-focused purchases often lead to equipment that creates greater risk than properly constructed alternatives.

Even seemingly minor components like thermometers, gauges, or clamps can create significant hazards if they fail during operation. Inaccurate temperature readings can lead to overheating, poor separation of toxic components, or unexpected vapor production. Failed clamps or fasteners can cause sudden leaks of hot liquid or vapor at critical moments during distillation runs.

Reputable equipment manufacturers provide specifications, material certifications, testing documentation, and clear usage guidelines. While quality equipment represents a greater initial investment, the safety margin it provides makes this one area where compromise creates disproportionate risk.

Carbon Monoxide Poisoning From Improper Ventilation

“Carbon Monoxide Poisoning Symptoms …” from cpraedcourse.com and used with no modifications.

Carbon monoxide (CO) poisoning represents a significant but often overlooked danger in distillation operations. This odorless, colorless gas produced by incomplete combustion of carbon-containing fuels can reach lethal concentrations in poorly ventilated spaces. Distillers using propane burners, natural gas heat sources, or solid fuels face particular risk, especially when operating in enclosed spaces like garages, basements, or outbuildings. For more information on safety practices, consider these safety tips for moonshiners.

The danger is magnified because carbon monoxide produces no sensory warnings—it has no smell, taste, or color, and causes no immediate irritation. Early symptoms including headache, dizziness, confusion, and fatigue are easily attributed to other causes or simply ignored. By the time more serious symptoms develop, victims may be too impaired to recognize the danger or take protective action. Understanding the parts of a still can help in taking preventive measures against such dangers.

How Heat Sources Generate Carbon Monoxide

Common distillation heat sources including propane burners, natural gas flames, and solid fuels all produce carbon monoxide as a byproduct of combustion. When these heat sources receive adequate oxygen and proper adjustment, CO production remains minimal. However, factors like inadequate ventilation, improper burner adjustment, or equipment malfunctions can dramatically increase carbon monoxide generation.

Propane burners, popular among home distillers for their portability and high heat output, produce significant CO when operating with a yellow or sooty flame instead of the proper blue flame. Natural gas heating elements similarly create elevated CO levels when improperly adjusted or when operating in oxygen-deficient environments. Even electric heating elements, while not directly producing carbon monoxide, can ignite nearby combustible materials that subsequently generate CO during smoldering. For those interested in the legal aspects of home distilling, you might want to explore whether stills are illegal in the US.

In confined spaces, carbon monoxide concentrations can reach dangerous levels surprisingly quickly. A single improperly adjusted medium-sized propane burner in a typical two-car garage can produce lethal CO concentrations within hours if ventilation is inadequate. The extended runtime typical of distillation sessions (often 4+ hours) creates extended exposure that compounds the risk.

Warning Signs You’re in Danger

The initial symptoms of carbon monoxide exposure—headache, dizziness, weakness, upset stomach, vomiting, chest pain, and confusion—mimic many common illnesses, making self-diagnosis difficult. These symptoms are easily attributed to flu, food poisoning, or general fatigue, especially when developing gradually during a lengthy distillation session. By the time symptoms become severe, cognitive impairment often prevents victims from recognizing the danger or taking appropriate action.

A critical warning sign is when multiple people in the same space develop similar symptoms simultaneously, or when symptoms improve after leaving the area and worsen upon return. Pets may show symptoms before humans, with unusual behavior, vomiting, or lethargy in animals providing an early warning that something is wrong in the environment.

Modern carbon monoxide detectors provide the most reliable protection, sounding alarms at CO concentrations well below those causing severe symptoms. These detectors should be installed in any space where combustion occurs and checked regularly to ensure proper operation. No distillation using combustion heat sources should ever occur without working CO detectors properly placed in the workspace.

Ventilation Requirements for Safe Distilling

Proper ventilation for distillation requires both removing harmful vapors (including carbon monoxide and alcohol vapors) and supplying adequate fresh air for complete combustion. For most home distillation setups, this means mechanical ventilation rather than passive airflow—typically exhaust fans rated for at least 100 cubic feet per minute, with higher capacities needed for larger burners or stills.

Ventilation systems should create negative pressure in the distillation area, drawing air in from outside rather than pushing indoor air outward. This prevents alcohol vapors from being forced into adjacent spaces where ignition sources might exist. Intake air should come from clean outdoor sources rather than from other indoor areas that might already contain carbon monoxide or other contaminants.

Beyond general room ventilation, direct venting of combustion products represents best practice for safety. This typically involves hood systems positioned directly above heat sources to capture emissions before they disperse into the workspace. Commercial distilleries implement sophisticated ventilation systems with multiple redundancies—a standard home distillers should attempt to approach even with simpler systems.

Contamination Risks in Home-Distilled Spirits

“contaminated spirits with Raman | Metrohm” from www.metrohm.com and used with no modifications.

Beyond immediate safety hazards, home distillation carries various contamination risks that can impact both product quality and consumer health. Metal contamination occurs when inappropriate materials contact the wash or vapors, potentially introducing toxic compounds into the final product. Bacterial contamination during fermentation or storage can produce both off-flavors and potentially harmful byproducts. Chemical residues from cleaning products or previous uses of equipment components add another contamination vector requiring careful management.

Unlike commercial producers who implement rigorous testing protocols, home distillers rarely have access to laboratory analysis that could identify contaminants before consumption. This places additional importance on preventive measures including proper material selection, sanitation protocols, and careful process management to minimize contamination risks from the outset.

Lead and Metal Leaching From Improper Equipment

Metal contamination represents one of the most serious long-term health concerns in home-distilled spirits. Lead solder, historically common in plumbing and still present in some imported stills, can leach into distillate causing neurotoxic effects that accumulate over time. Even low-level chronic lead exposure causes significant health impacts including cognitive impairment, reproductive issues, kidney damage, and cardiovascular effects.

Other problematic metals include zinc from galvanized components, which causes immediate gastrointestinal distress in sufficient quantities and long-term issues with chronic exposure. Copper, while essential to proper distillation in appropriate amounts, can reach harmful levels if acidic solutions contact copper surfaces for extended periods, particularly in poorly designed equipment where excessive copper contact occurs.

Proper equipment should use only food-grade stainless steel (304/316 grade), pure copper, or laboratory-grade glass components. All connections should use appropriate food-grade materials including silver solder (when necessary), PTFE tape, or appropriate gaskets rated for food contact and high-temperature alcohol exposure. Any equipment with unknown composition or history should be avoided regardless of apparent condition or price advantage. For more information on the essential components of a still, you can explore the three main parts of a still.

Bacterial Contamination in Fermentation

Bacterial contamination during fermentation can produce compounds that carry through distillation, affecting both flavor and safety. While ethanol kills many microorganisms, certain bacteria thrive in the acidic, alcoholic environment of fermentation, producing byproducts ranging from unpleasant flavors to potentially harmful compounds. Proper sanitation, pH management, and fermentation temperature control represent crucial safeguards against these contaminants.

Of particular concern are bacteria that produce biogenic amines like histamine and tyramine, which can cause allergic-type reactions, headaches, and cardiovascular effects in sensitive individuals. These compounds can concentrate during distillation and persist in the final product. Proper yeast management, controlled fermentation conditions, and adequate mash preparation help minimize these bacterial contaminants.

Sanitation throughout the process remains the primary defense against bacterial contamination. Food-grade sanitizing solutions (properly rinsed before use), clean water sources, and careful handling protocols help ensure that fermentation produces the intended compounds rather than bacterial byproducts that could impact safety or quality. For those interested in understanding more about the equipment used in this process, exploring the main parts of a still can be insightful.

Chemical Contaminants From Cleaning Products

Chemical contamination from cleaning products or previous use of containers represents another significant risk in home distillation. Many common cleaning products leave residues that can be carried over into the distillate during processing. Particularly concerning are quaternary ammonium compounds (quats), chlorine-based sanitizers without proper rinsing, and petroleum-based cleaners that leave films resistant to water rinsing.

Equipment with unknown history presents special concerns, as containers previously used for chemicals, fuels, or industrial purposes may harbor residues that cannot be adequately removed through cleaning. This applies particularly to plastic components which can absorb compounds from previous contents and later release them during distillation.

Safe practice requires using only new food-grade containers or those with known food-safe history, cleaning with appropriate food-grade detergents and sanitizers, and thorough rinsing with potable water before use. When sanitizing chemicals are used, manufacturer guidelines for concentration, contact time, and rinsing requirements must be followed precisely to prevent chemical carryover.

Essential Safety Equipment Every Distiller Needs

“Alcohol Distiller Manufacturer” from distillequipment.com and used with no modifications.

Proper safety equipment represents a non-negotiable investment for anyone learning about distillation. The minimum safety kit includes appropriate fire suppression equipment, ventilation systems, monitoring tools, and personal protective gear. While commercial operations implement comprehensive safety systems with redundancies and engineering controls, even educational distillation setups require these basic protections to prevent accidents and injuries.

Beyond equipment, proper training in emergency procedures, regular practice of safety protocols, and developing a safety-first mindset contribute significantly to risk reduction. Many distillation accidents result not from equipment failure but from operator errors, shortcuts, or failure to follow established safety procedures—highlighting the importance of both proper equipment and proper mindset.

Fire Extinguishers and Suppression Systems

Every distillation operation requires appropriate fire suppression equipment within immediate reach. The minimum requirement is a properly sized ABC dry chemical fire extinguisher rated for flammable liquid fires (Class B). For larger setups, multiple extinguishers positioned at different access points provide redundancy in emergency situations. It’s also important to be aware of legal considerations when setting up your distillation equipment.

Beyond portable extinguishers, fixed suppression systems provide additional protection for dedicated distillation spaces. Options range from simple heat-activated fire alarm systems to sophisticated automatic suppression using appropriate agents for alcohol fires. Commercial distilleries typically implement multi-layered fire protection including sprinklers, specialized suppression systems, and comprehensive detection equipment—standards home distillers should consider when designing safe operations.

All fire safety equipment requires regular inspection and maintenance to ensure functionality when needed. Extinguishers should be checked monthly for proper pressure and condition, with professional inspection and servicing according to manufacturer guidelines. Everyone involved in distillation activities should receive training in proper extinguisher use, fire response procedures, and emergency evacuation plans.

Proper Ventilation Setup

Adequate ventilation serves multiple safety functions in distillation, removing alcohol vapors, dissipating heat, and preventing carbon monoxide accumulation. The minimum ventilation requirement includes mechanical exhaust capable of completely exchanging the air in the distillation space multiple times per hour, with rates increasing based on the size of the operation and heat sources used. For more safety tips on home distilling, check out these 7 safety tips for distilling at home.

Proper ventilation design considers both general room ventilation and source capture for specific emission points. Exhaust positioning should create airflow patterns that move vapors away from operators and ignition sources toward controlled collection points. Intake air should come from clean outdoor sources rather than recirculating potentially contaminated indoor air. For more safety measures, you can check out these safety tips for moonshiners.

Ventilation systems should operate on independent electrical circuits from distillation equipment, ensuring continued operation even if equipment malfunctions occur. Emergency backup power for ventilation represents best practice, particularly for operations using combustion heat sources where power loss could create dangerous carbon monoxide accumulation.

Temperature and Pressure Monitoring Tools

Accurate temperature monitoring throughout the distillation process provides critical safety information while ensuring proper separation of different fractions. Digital thermometers with appropriate probes for vapor temperature measurement allow precise tracking of still head temperatures, enabling proper identification of foreshots, heads, hearts, and tails fractions. Secondary temperature monitoring at the boiler, condenser input, and output provides comprehensive process control information while alerting operators to potential problems before they become dangerous.

Pressure monitoring equipment, while less common in simple pot still setups, becomes essential for any system with restricted vapor paths, reflux components, or complex design. Proper pressure gauges rated for the temperatures involved should be installed at appropriate points in the vapor path, with pressure relief mechanisms preventing dangerous over-pressurization. These monitoring tools serve as early warning systems for potential equipment failures or operator errors.

Modern distillation often incorporates digital monitoring systems that provide real-time data logging, automated alerts, and emergency shutdown capabilities when parameters exceed safe ranges. While complex digital systems may exceed home distiller requirements, basic digital temperature monitoring represents an affordable safety enhancement over traditional analog methods. For those interested in ensuring safety, consider these safety tips for distilling at home.

Personal Protective Equipment Requirements

Appropriate personal protective equipment (PPE) provides the last line of defense against distillation hazards. Heat-resistant gloves rated for temperatures exceeding boiling points protect against burns when handling hot equipment, adjusting components, or responding to leaks or spills. Full-length clothing made from natural fibers (cotton, wool) rather than synthetic materials provides basic protection against flash fires and small splashes of hot liquid.

Eye protection remains essential during all distillation operations, with splash-resistant safety glasses or goggles preventing eye injuries from unexpected releases of hot liquid or vapor. For operations involving pressure equipment or chemical handling (like cleaning solutions), full-face protection may be appropriate. Some distillers also implement flame-resistant aprons or coveralls for additional protection during higher-risk operations like heating flammable washes.

Respiratory protection becomes important when working with high-proof alcohol or during cleaning operations using chemical sanitizers. Appropriate respirators with cartridges rated for organic vapors provide protection against both alcohol vapors and cleaning chemical fumes that could cause respiratory irritation or more serious health effects with prolonged exposure. For more information on safety concerns, you might want to explore the legality of stills in the US.

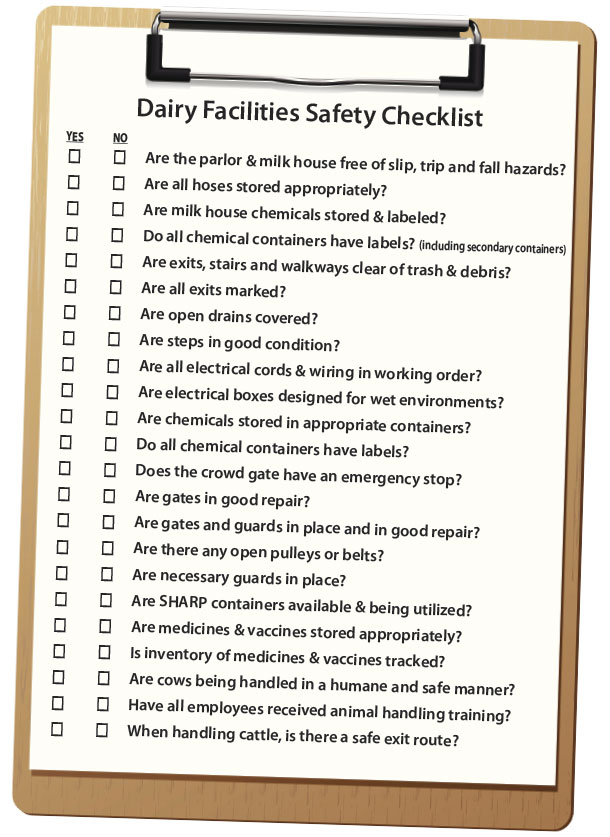

Creating Your Distilling Safety Checklist

“Dairy facilities safety checklist …” from www.agproud.com and used with no modifications.

Developing a comprehensive safety checklist tailored to your specific equipment and environment provides a systematic approach to risk management. Each distillation session should begin with a methodical equipment inspection, environment assessment, and safety equipment verification. Standard operating procedures should include specific safety steps integrated throughout the process rather than treated as separate considerations.

Written checklists serve several important purposes beyond simple reminders. They create standardized procedures that don’t rely on memory, especially important when distractions occur. They provide documentation of safety practices which could prove valuable in various situations. Perhaps most importantly, they establish a safety-conscious culture where verification and caution become habitual rather than exceptional.

Effective checklists evolve over time, incorporating lessons from each distillation session and adapting to equipment modifications or process changes. Regular review and updating of safety procedures represent hallmarks of conscientious operation, with each distillation building not just skill but safer practices. For those curious about the legal aspects, it’s important to understand are stills illegal in the US to ensure compliance with local regulations.

When developing your safety protocols, consider organizing them into distinct phases: pre-run preparation, startup procedures, running operations, shutdown sequences, and post-run cleanup. Each phase presents unique hazards requiring specific precautions and verification steps. To better understand the equipment involved, you might want to explore the three main parts of a still, which can help in identifying potential risks and ensuring a safer distilling process.

- Develop written procedures for normal operations and emergencies

- Include equipment-specific safety checks based on manufacturer recommendations

- Create clear decision trees for addressing common problems

- Establish communication protocols if multiple people are involved

- Schedule regular practice of emergency procedures

- Document incidents, near-misses, and safety improvements

- Review and update procedures regularly based on experience

Pre-Run Safety Inspection Steps

Before each distillation run, conduct a thorough equipment inspection focusing on safety-critical components. Check all connections for tightness and proper sealing, inspect gaskets and seals for signs of degradation, and verify that condensers, tubes, and pathways remain unobstructed. Pressure relief mechanisms deserve special attention, ensuring they operate freely and remain unmodified from their designed function.

During Distillation Monitoring Protocol

Active monitoring during distillation provides early detection of developing problems before they become emergencies. Establish regular inspection intervals for checking temperatures at key points, verifying proper condenser function, monitoring collection rates, and inspecting for any liquid or vapor leaks. Create written parameters for normal operation and clear action thresholds indicating when intervention becomes necessary.

Post-Run Equipment Checks

After completing a distillation run, systematic shutdown and equipment inspection prevents creating hazards for future sessions. Allow equipment to cool completely before disassembly, verify that all pressure has dissipated, and inspect components for signs of stress, wear, or damage that could create future safety issues.

- Clean equipment thoroughly using appropriate food-grade cleaners

- Inspect gaskets and seals for compression set or damage

- Check heating elements for proper function and wiring integrity

- Examine cooling systems for scale buildup or efficiency loss

- Document any anomalies or components requiring replacement

- Store equipment properly to prevent damage between uses

- Secure any collected distillate in appropriate containers away from heat sources

Documentation represents an often-overlooked aspect of post-run procedures. Maintaining records of operating parameters, equipment condition, and any unusual events provides valuable information for troubleshooting and process improvement. These records also establish a history of careful operation and safety consciousness.

Proper cleaning after each run prevents contamination issues in subsequent batches while providing another opportunity to inspect equipment thoroughly. Use only appropriate cleaning agents, follow proper dilution guidelines, and ensure complete rinsing of any cleaning chemicals before storage or reuse. For more detailed guidance on equipment maintenance, you can explore the onion head on a still and its role in the distillation process.

Emergency Shutdown Procedures

Every distillation operation needs clear emergency shutdown procedures that can be executed quickly under stress. The primary steps typically include removing heat sources immediately, ensuring ventilation continues operating, addressing any fire or spill with appropriate suppression methods, and evacuating if necessary. These procedures should be written in clear, simple language, posted visibly in the distillation area, and practiced regularly.

Different emergency scenarios may require modified responses, but having a basic shutdown sequence committed to memory provides a starting point for addressing most situations. Practice scenarios should include common emergencies like minor fires, pressure buildups, liquid leaks, and power failures to build confidence in emergency response capabilities.

Staying Safe While Still Enjoying the Craft

“Making Moonshine is Safer Than You Think -” from brewhaus.com and used with no modifications.

Understanding distillation safety doesn’t mean abandoning interest in traditional crafts—it means approaching them with appropriate knowledge, equipment, and precautions. Many enthusiasts explore distillation heritage and techniques through legal channels including commercial craft distillery experiences, educational workshops at licensed facilities, or focusing on the non-distillation aspects of spirits production like fermentation science and flavor development. The rich cultural heritage and fascinating science behind distillation can be appreciated without necessarily engaging in illegal production.

Frequently Asked Questions

The following questions address common misconceptions and important clarifications regarding distillation safety. While this information is provided for educational purposes, remember that implementing proper safety measures requires understanding underlying principles rather than simply following isolated recommendations.

Safety information continues to evolve as research provides new insights and equipment technology advances. Staying current with best practices requires ongoing education through legitimate sources including professional distilling organizations, accredited educational programs, and peer-reviewed scientific literature. For those interested in the legal aspects, it’s crucial to understand whether stills are illegal in the US to ensure compliance with regulations.

Is it ever legal to distill alcohol at home in the US?

No. Federal law prohibits distilling alcohol at home without appropriate federal permits regardless of purpose, quantity, or local regulations. While some states have modified their laws regarding distillation, federal prohibition remains the controlling legal standard throughout the United States. The only legal pathways involve obtaining proper federal permits (either as a commercial distillery or for fuel alcohol production), which require substantial regulatory compliance, tax payment, and approved facilities. For those interested in the secret history of corn moonshine, understanding the legal landscape is crucial.

How can I test for methanol in my distilled spirits?

There is no reliable home testing method for methanol in spirits. Professional distilleries use laboratory equipment including gas chromatography to measure methanol content—equipment far beyond home distiller resources. Claims about flame color tests, taste tests, or simple chemical reactions providing methanol detection are dangerous myths without scientific validity.

The only reliable approach for methanol safety is proper distillation technique, including conservative discarding of foreshots and early heads fractions. Commercial distilleries combine proper technique with laboratory verification to ensure safety—a dual approach that provides the redundancy needed for consumer protection. For those interested in the mechanics of distillation, understanding the three main parts of a still is crucial for effective and safe production.

Methanol Safety Facts

- No reliable home test exists for methanol detection

- Methanol poisoning symptoms resemble severe intoxication

- As little as 10ml of methanol can cause permanent blindness

- Methanol concentrates in early distillation fractions

- Proper fraction separation remains the only reliable home safety measure

- Seek immediate medical attention if methanol poisoning is suspected

Medical treatment for suspected methanol poisoning requires immediate emergency care. The primary treatment involves administering ethanol or fomepizole to block methanol metabolism while hemodialysis removes the toxin from the bloodstream. Early intervention significantly improves outcomes, but permanent damage may still occur depending on exposure amount and treatment timing. For more on safety, check out these important safety tips for moonshiners.

What’s the safest heat source for home distilling?

Electric heating elements specifically designed for distillation provide the safest heat source option, eliminating open flames and reducing carbon monoxide risks. These elements offer precise temperature control, even heat distribution, and can include safety features like automatic shutoffs and temperature limiting. When properly installed with appropriate wiring, circuit protection, and controls, electric heating significantly reduces fire and explosion hazards compared to flame-based alternatives.

If electric heating isn’t possible, indirect heating methods like water or oil baths provide secondary safety advantages by distributing heat more evenly and creating thermal buffering that prevents rapid temperature changes. These approaches reduce the risk of scorching, which can lead to flavor issues and potentially dangerous material degradation in direct-fired setups.

Can I convert my brewing setup to distilling safely?

Converting brewing equipment to distillation purposes creates significant safety concerns beyond the legal issues involved. Brewing equipment typically lacks the vapor management capabilities, pressure tolerance, temperature resistance, and material compatibility needed for safe distillation. Particularly dangerous modifications include attempting to seal brewing fermenters for vapor collection or adapting beer kegs without proper engineering, pressure relief, and material consideration.

What should I do if a distilling fire starts?

If a small, contained fire occurs, use an appropriate Class B fire extinguisher (rated for flammable liquids) aimed at the base of the flames, maintaining safe distance and following the PASS technique (Pull, Aim, Squeeze, Sweep). Immediately shut down all heat sources if possible without endangering yourself. For larger fires or ones involving alcohol, evacuate immediately, close doors to contain the fire if safe to do so, and call emergency services from a safe location.

Never use water on alcohol fires as it can spread the flames and potentially create dangerous steam explosions when contacting hot equipment. If clothing catches fire, remember to stop, drop, and roll rather than running, which fuels flames with additional oxygen. Proper pre-planning for fire emergencies, including establishing primary and alternate exit routes, significantly improves outcomes when emergencies occur.

Whiskey Still Pro provides comprehensive educational resources about traditional distillation methods while emphasizing safety above all else. Their learning materials help enthusiasts understand both the science and historical significance of distillation while remaining compliant with applicable laws.