Exploding Moonshine Stills Explained: 4 Common Causes and Fixes

Key Takeaways

- Modern moonshine stills are designed as open atmospheric systems, virtually eliminating explosion risks when properly constructed and operated

- The four main causes of still explosions are pressure buildup, alcohol vapor ignition, faulty equipment, and operator error

- Proper ventilation is critical when distilling as alcohol vapors are highly flammable and can reach dangerous concentrations in confined spaces

- Never use sealed containers or automotive radiators for distillation as they can create deadly pressure or introduce toxic metals

- Brewhaus distilling equipment features essential safety measures including pressure relief mechanisms and lead-free construction

That terrifying “BOOM!” you’ve heard about in moonshine lore isn’t as common as movies would have you believe. While distillation accidents do happen, they’re almost entirely preventable with proper knowledge and equipment. Brewhaus has been providing safe, professional-grade distillation equipment for years, and we’re committed to helping hobbyists understand the science behind distillation safety.

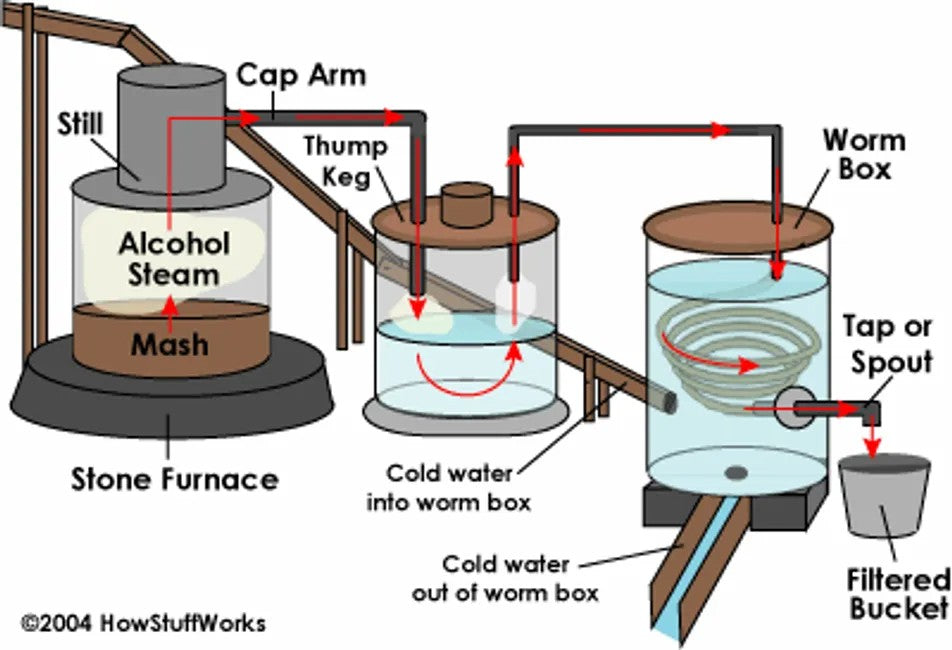

The truth is that modern moonshine stills, when properly constructed and operated, present minimal explosion risks. Today’s stills are designed as open systems that naturally prevent pressure buildup—the primary culprit behind the dramatic explosions of prohibition-era distillers. Let’s examine the actual science behind these incidents and how to prevent them.

Pressure Buildup: The Silent Danger

“The Pressure Buildup Well Test Analysis …” from onlinelibrary.wiley.com and used with no modifications.

The most common cause of still explosions is pressure accumulation within a sealed system. Unlike pressure cookers that can operate at 15+ PSI, a properly designed still should never exceed 1 PSI of internal pressure. When vapor has nowhere to escape, pressure builds until the weakest point fails—often catastrophically.

How Pressure Accumulates in Closed Systems

When alcohol is heated in a sealed container, the liquid expands and vaporizes, dramatically increasing the pressure. Think about what happens when you seal a plastic bottle and leave it in a hot car—now imagine that with alcohol vapor that’s expanding even more rapidly. In properly designed stills like those from Brewhaus, the vapor path is always open to atmospheric pressure, allowing vapor to flow freely through the condenser without building pressure. If you’re curious about how much liquor you can produce, you might want to check out how much whiskey a 5-gallon still can make.

The fundamental rule of still design is simple: a still must be an open system. If vapor can’t escape freely, pressure builds and creates a potential bomb. This is why makeshift stills using sealed containers like pressure cookers with welded-on pipes are incredibly dangerous. For more information on safety, you might want to explore why your moonshine mash might not be bubbling, which could indicate issues in your setup.

Signs Your Still is Under Dangerous Pressure

While a properly designed still should never experience dangerous pressure, it’s crucial to recognize warning signs. Hissing sounds, bulging metal, or vibrations are immediate red flags. If your condenser stops producing distillate while heat is still applied, this could indicate a blockage creating pressure. Any connections that show signs of leaking vapor rather than directing it through the intended path also indicate a potential pressure problem.

If you observe any of these warning signs, immediately cut heat to your still and allow it to cool completely before investigating the cause. Never attempt to adjust connections or open a still that appears to be under pressure. For more insights, you might want to understand how much liquor 10 gallons of mash can make.

Installing Proper Pressure Relief Valves

Professional still designs incorporate multiple safety features to prevent pressure buildup. The most important is an open vapor path that’s never restricted. Some advanced designs include purpose-built pressure relief valves that will vent excess pressure before it reaches dangerous levels. If you’re experiencing issues like your moonshine mash not bubbling, it might be related to improper pressure management.

For home distillers, the safest approach is using professionally designed equipment with these features already incorporated. Brewhaus stills feature open atmospheric designs where the vapor path remains unrestricted throughout the distillation process, eliminating the risk of dangerous pressure accumulation.

Alcohol Vapor Ignition

“The Vaportini: A Cocktail Inhaled, Not …” from www.kuer.org and used with no modifications.

The second most common cause of still accidents isn’t an explosion from pressure, but rather a fire from ignited alcohol vapor. Alcohol vapor is highly flammable and heavier than air, meaning it can flow across surfaces and reach distant ignition sources.

Why Alcohol Vapors Are Highly Flammable

Ethanol vapor reaches its flammable range at just 3.3% concentration in air—far lower than many other common flammable substances. At this concentration, any spark or flame can ignite the vapor, causing a flash fire that can quickly spread to nearby flammable materials. The invisible nature of alcohol vapor makes it particularly dangerous, as it can spread without detection until it reaches an ignition source.

Common Ignition Sources Near Stills

The most dangerous ignition sources around distillation setups are open flames, electrical sparks, and hot surfaces. Gas burners, cigarettes, pilot lights, electric motors, light switches, and even static electricity can ignite alcohol vapor. This is why traditional outdoor distillation using propane burners can be particularly hazardous without proper ventilation and safety measures.

Many distillation accidents occur when operators use propane burners in enclosed spaces or when electric heating elements short out during operation. Even the seemingly innocent act of turning on a light switch can create a tiny spark capable of igniting concentrated alcohol vapor.

Creating a Vapor-Safe Distillation Area

Designing a safe distillation space requires eliminating potential ignition sources and ensuring proper ventilation. Induction heating has become increasingly popular among safety-conscious distillers because it eliminates open flames. If using electric heating elements, ensure they’re properly maintained and designed for distillation use.

Maintain a minimum 10-foot clearance between your still and any potential ignition sources. This includes gas water heaters, furnaces, electric motors, switches, and other spark-producing equipment. Remember that alcohol vapor flows downward and can travel significant distances along floors and surfaces.

Proper Ventilation Requirements

Ventilation is your primary defense against vapor accumulation. A proper distillation area requires at least 4 air changes per hour—meaning the entire volume of air in your distillation space should be replaced four times every hour. For most home distillers, this means using fans to ensure consistent airflow and prevent vapor pockets from forming. To understand more about distillation processes, you might want to learn how much whiskey a 5-gallon still can produce.

Installing vapor monitors that can detect alcohol concentration in air provides an additional safety margin. These devices, similar to carbon monoxide detectors, can alert you before vapor reaches dangerous levels. Remember that your nose isn’t reliable for detecting alcohol vapor, especially after prolonged exposure dulls your senses.

Faulty Equipment and Poor Construction

“Common Injuries from Faulty and Unsafe …” from www.thezlawfirm.com and used with no modifications.

The quality of your still directly impacts safety. Poorly constructed equipment using inappropriate materials creates both explosion and contamination risks. Cutting corners on still construction might save money initially but dramatically increases danger during operation. Investing in properly designed equipment from reputable manufacturers like Brewhaus ensures both safety and quality output.

Dangerous Materials to Avoid in Still Construction

Lead is the most notorious danger in homemade stills. Historically, moonshiners sometimes used lead solder or car radiators containing lead, resulting in toxic distillate that caused blindness, organ damage, and death. Modern copper stills use lead-free solder and food-grade materials to eliminate this risk. Brewhaus exclusively uses lead-free construction methods and materials that meet food-grade standards.

Aluminum, galvanized metals, and certain plastics can also leach harmful chemicals during distillation. Copper remains the gold standard for still construction because it not only conducts heat efficiently but also reacts with and removes sulfur compounds that would otherwise make the distillate unpalatable. Stainless steel is another acceptable material when properly specified for food-grade applications.

The Problem with Repurposed Equipment

Repurposing everyday items like pressure cookers, beer kegs, or radiators for distillation creates significant safety hazards. These items weren’t designed for distillation’s unique requirements and often contain inappropriate materials or can’t handle the thermal cycling involved. Car radiators are particularly dangerous as they typically contain lead solder and other toxic metals that can leach into your distillate.

Pressure cookers present another serious hazard when modified for distillation. These vessels are designed to maintain pressure, not release it continuously as required for safe distillation. Attempting to adapt pressure cookers by drilling and attaching condenser tubes creates weak points that can fail catastrophically under pressure.

Essential Safety Features Every Still Needs

A properly designed still incorporates several critical safety features: an unrestricted vapor path that prevents pressure buildup, secure but removable connections that won’t fail under normal operation, temperature monitoring capabilities, and proper materials throughout the vapor path. Professional stills from manufacturers like Brewhaus incorporate these features by design, with open atmospheric systems that physically cannot build dangerous pressure levels when used as directed.

Operator Error and Lack of Knowledge

“The destructiveness of a lack of …” from www.scottfreeclinic.org and used with no modifications.

Even with perfect equipment, operator mistakes cause many distillation accidents. Understanding the science behind distillation and following proper procedures are essential safety components. Most accidents occur when distillers rush, become distracted, or skip crucial safety steps because they don’t understand their importance. For those interested in how much liquor can be produced, it’s important to know how much liquor 10 gallons of mash make to avoid errors during the process.

Temperature Management Mistakes

One of the most common operator errors is applying too much heat too quickly. Rapid heating can cause liquid to boil violently, potentially forcing liquid into the vapor path and causing blockages. This “puking” effect creates pressure behind the blockage and can lead to failure at connection points. Always start with gentle heat and increase gradually, maintaining a steady distillation rate rather than attempting to maximize output through excessive heat.

Another critical temperature-related mistake is leaving a still unattended. Distillation requires constant monitoring to ensure temperature remains in the safe range and to watch for signs of trouble. Never walk away from an operating still, even for a few minutes. The time saved isn’t worth the potential catastrophic consequences.

Overlooking Maintenance Requirements

Stills require regular inspection and maintenance to remain safe. Copper stills develop verdigris (green copper oxide) over time that must be cleaned properly before use. Connections can loosen through thermal cycling, creating potential vapor leaks. Condensers can become partially blocked with residue, restricting vapor flow and potentially creating pressure. For more insights on maintaining your stills, you might want to explore how to make infused moonshine safely.

Before each distillation run, thoroughly inspect all components of your still. Check for clear vapor paths, secure connections, and signs of wear or damage. This simple pre-flight check can identify potential problems before they become dangerous. For more insights, you might want to explore how to make infused moonshine.

1. Always Monitor Your Still During Operation

Never leave an operating still unattended, even briefly. Changes in pressure, temperature, or flow can develop rapidly and require immediate attention. Keep a spray bottle of water nearby to extinguish small fires should they occur, and have a properly rated fire extinguisher within reach. Remember that water should never be applied to alcohol fires in quantity as it can spread the flames—small misting applications are safest for minor incidents.

2. Never Use Sealed Containers

This point cannot be emphasized enough: a still must always be an open system. Never attempt to distill in a sealed container or one where the vapor path can become fully blocked. Pressure cookers, without significant modification and safety additions by experienced engineers, are never appropriate for distillation. Professional stills are designed with multiple paths for pressure relief, ensuring they remain at atmospheric pressure during operation.

3. Keep Heat Sources Properly Maintained

Whether using electric elements, induction plates, or other heating methods, regular maintenance is essential. Inspect wiring for signs of wear, ensure heating elements are functioning properly, and verify that temperature control systems are accurate. Faulty heating equipment not only reduces efficiency but can create serious safety hazards through unexpected temperature spikes or electrical failures.

4. Learn Before You Distill

Take the time to understand the science and safety requirements before attempting distillation. Join online communities, read reliable resources, and consider apprenticing with experienced distillers if possible. The knowledge gained will not only keep you safe but also improve your results. Brewhaus offers extensive educational resources specifically designed for home distillers to ensure they understand both the how and why of safe distillation practices.

Modern Still Design Safety Features

“MOONSHINE STILL – Hobby Distillers …” from www.thedistillerynetwork.com and used with no modifications.

Today’s commercially manufactured stills bear little resemblance to the dangerous contraptions of prohibition lore. Modern designs incorporate numerous safety features that physically prevent many common accident causes. Brewhaus stills, for example, use open atmospheric designs that make pressure buildup virtually impossible during normal operation.

Open Atmospheric Systems vs. Pressurized Systems

The fundamental difference between safe and dangerous still designs is whether they operate as open or closed systems. Open atmospheric systems maintain constant pressure equilibrium with the surrounding environment, allowing vapor to flow freely through the condenser without building pressure. These systems physically cannot explode from pressure when used as designed because there’s no mechanism for pressure to accumulate. If you’re curious about the output of different still sizes, you might want to check out how much whiskey a 5-gallon still can produce.

Pressurized systems, by contrast, contain the vapor within a sealed container, allowing pressure to build. While these systems have applications in commercial distillation under carefully controlled conditions, they’re never appropriate for home distillers. The safety margins are simply too narrow and the consequences of failure too severe.

Modern column stills use a series of plates or packing to achieve multiple distillations in a single pass. These designs maintain open atmospheric pressure throughout while increasing efficiency and control. The vapor path remains unrestricted, with pressure relief built into the fundamental design rather than added as an afterthought.

- Open atmospheric systems physically prevent pressure buildup

- Proper still design includes unrestricted vapor paths

- Multiple reflux points increase efficiency without increasing danger

- Secure but non-permanent connections prevent catastrophic failures

- Temperature monitoring points allow for precise control

Electric vs. Gas Heat Sources

While traditional distillers often used open flames, modern systems typically employ safer heating methods. Electric elements designed specifically for distillation provide precise temperature control without introducing an ignition source for alcohol vapor. Induction heating represents the cutting edge in still safety, using magnetic fields to generate heat in the still’s base without any exposed heating elements or flames. These advanced heating methods dramatically reduce fire risks while improving consistency and control. For those interested in distillation techniques, understanding at what temperature to add yeast to your mash can also enhance your distillation process.

Professional vs. DIY Still Safety Comparison

Professional stills from reputable manufacturers like Brewhaus incorporate safety features developed through decades of engineering and practical experience. These systems use appropriate materials, incorporate multiple redundant safety features, and are designed to fail safe rather than catastrophically. While DIY stills might save money initially, they often lack these critical safety features and may use inappropriate materials that create both safety and quality issues. The cost difference is insignificant compared to the potential consequences of a serious distillation accident, such as when temperature kills distillers yeast.

Stay Safe and Enjoy the Craft

“white background Stock Photo …” from www.alamy.com and used with no modifications.

Distillation can be a rewarding hobby when approached with proper knowledge and equipment. The key is understanding that safety isn’t optional or something to compromise on—it’s the foundation that makes everything else possible. By using properly designed equipment, ensuring adequate ventilation, eliminating ignition sources, and following proper procedures, the risks associated with home distillation can be reduced to levels comparable to other common hobbies. Brewhaus is committed to providing both the equipment and knowledge needed for safe, successful distillation experiences.

Frequently Asked Questions

Home distillation generates many questions, particularly around safety concerns. Below are answers to some of the most common inquiries we receive about still explosions and safety measures. Remember that knowledge is your best protection against accidents.

Distillation safety has evolved significantly over the decades. Modern understanding of the science involved, combined with purpose-built equipment, has virtually eliminated the dangers that gave moonshining its dangerous reputation. By following proper procedures and using appropriate equipment, today’s distillers can practice their craft with minimal risk. For those interested in the distillation process, understanding how much whiskey a 5-gallon still can produce can be a valuable part of the learning experience.

The distillation community continues to advance safety standards through information sharing and technological improvements. Organizations like Brewhaus contribute to this evolution by developing equipment specifically designed to prevent common accident causes and by educating distillers about proper safety protocols.

- Never distill in confined spaces without proper ventilation

- Always use open atmospheric still designs that prevent pressure buildup

- Keep heat sources properly maintained and appropriate for distillation

- Eliminate all potential ignition sources from the distillation area

- Monitor the still continuously throughout the distillation process

Can a moonshine still explode even if I’m careful?

Modern properly designed stills operated correctly have virtually zero explosion risk. The key is using an open atmospheric system that physically cannot build pressure. If your still is designed with an unrestricted vapor path and you maintain it properly, pressure explosions become practically impossible. The primary remaining risk would be fire from ignited alcohol vapor, which is prevented through proper ventilation and elimination of ignition sources.

Is it legal to own a still for distilling water or essential oils?

In the United States, owning a still of any size is legal, but using it to produce alcohol without proper permits violates federal law. Stills used exclusively for water purification, essential oil production, or fuel alcohol (with proper permits) are legal to operate. However, laws vary internationally, so always check local regulations. Brewhaus equipment is sold for legal purposes including water distillation, essential oil production, and properly permitted alcohol production. To understand more about still usage, you might want to explore how much whiskey a 5-gallon still can produce.

What’s the safest heat source for home distillation?

Induction heating provides the best safety profile for home distillation because it eliminates open flames and exposed heating elements that could ignite alcohol vapor. Electric heating elements designed specifically for distillation are also relatively safe when properly installed and maintained. Gas burners should only be used outdoors with excellent ventilation and careful attention to vapor management.

How far should my still be from any ignition sources?

Maintain a minimum 10-foot clearance between your still and any potential ignition sources. This includes pilot lights, electric motors, switches, heating elements, and other spark-producing equipment. Remember that alcohol vapor is heavier than air and flows downward, potentially reaching distant ignition sources along the floor. If you are concerned about your setup, you might also want to consider troubleshooting your moonshine mash to ensure everything is running smoothly.

If using your still in a garage or outbuilding, be particularly cautious about water heaters, furnaces, and other appliances with pilot lights or heating elements that cycle on automatically. These can ignite vapor without warning if proper clearance and ventilation aren’t maintained.

Can plastic stills really be safe for distillation?

Plastic components are never appropriate for the heated portions of a still or for parts that contact hot vapor. Certain food-grade plastics are acceptable for condensers and collection vessels where temperatures remain relatively low. The primary concerns with plastic are heat resistance, chemical compatibility, and potential chemical leaching. Purpose-designed plastic condensers from reputable manufacturers can be safe when used as directed, but DIY plastic components introduce significant risks. If you’re curious about how much whiskey a 5-gallon still can produce, it’s important to use appropriate materials to ensure safety and efficiency.

Copper and stainless steel remain the gold standards for still construction due to their heat resistance, durability, and safety profiles. These materials can withstand the temperatures involved in distillation without degrading or releasing harmful chemicals. They also provide better heat transfer characteristics, improving efficiency and control.

For those serious about distillation as a hobby or potential business, investing in proper equipment made from appropriate materials is essential. The relatively small additional cost provides significant safety and quality benefits that make the investment worthwhile. Brewhaus offers a range of professional-grade stills designed specifically for safe home use.