What Temperature Kills Distiller’s Yeast? Complete Guide to Fermentation Temps

Key Takeaways

- Distiller’s yeast typically dies at temperatures between 95-105°F (35-40°C), while specialized heat-tolerant varieties can survive up to 110°F (43°C).

- The ideal fermentation temperature for most distiller’s yeast strains is between 75-85°F (24-29°C) for maximum alcohol yield.

- Temperature control is critical – fermentation creates heat, so ambient temperatures should be 5-7°F cooler than your target fermentation temperature.

- Signs of overheated yeast include stalled fermentation, off flavors, and reduced alcohol production.

- Simple temperature control methods like wet t-shirt evaporative cooling can save your fermentation without expensive equipment.

Temperature control can make or break your distilling efforts. While many home distillers focus on equipment and ingredients, the silent killer of great spirits is often improper fermentation temperatures. Get this wrong, and you might end up with weak alcohol content, off flavors, or a completely stalled fermentation.

As an experienced distiller who’s made every temperature mistake possible, I’ve compiled this definitive guide to help you avoid the pitfalls of improper fermentation temperatures. Still Spirits has pioneered research into how temperature affects yeast performance, offering insights that can transform your distilling results by understanding these critical thresholds.

The Deadly Temperature Threshold for Distiller’s Yeast

“DADY Distillers Yeast – 1 lb – High …” from highaltitudehomebrew.com and used with no modifications.

When it comes to distiller’s yeast, temperature isn’t just a preference—it’s a matter of life and death for your microorganisms. Just like humans can’t survive extreme heat, yeast cells have their breaking point. Unlike humans though, yeast can’t move to cooler areas when things get too hot.

Most distiller’s yeast strains begin to struggle at temperatures above 90°F (32°C). As temperatures climb, fermentation activity initially increases but quickly turns problematic. At around 95-105°F (35-40°C), standard distiller’s yeast cells begin to die off rapidly, causing fermentation to stall completely. This temperature threshold is lower than many beginners realize, which explains why so many first-time distillers fail during summer months.

Understanding Yeast’s Temperature Tolerance

“Temperature on Yeast Fermentation …” from pricklycider.com and used with no modifications.

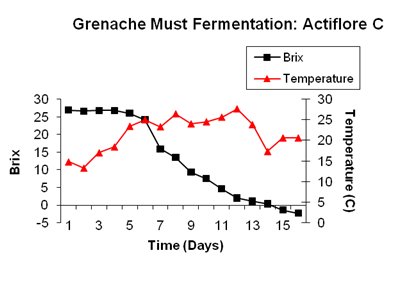

Temperature tolerance in yeast isn’t simply about survival—it’s about metabolic efficiency. At optimal temperatures, yeast cells efficiently convert sugars to alcohol and desirable flavor compounds. When temperatures drift outside ideal ranges, yeast metabolism changes dramatically, creating stress responses that affect both alcohol production and flavor development.

Think of yeast like a factory production line. At the perfect temperature, workers (enzymes) move efficiently, product quality is high, and output is consistent. As temperatures rise, initially production speeds up (faster fermentation), but quality control suffers (off flavors). When it gets too hot, workers collapse (yeast dies), and production stops entirely.

- Too cold (below 60°F/15°C): Yeast becomes dormant, fermentation stalls

- Ideal range (65-85°F/18-29°C): Efficient fermentation, balanced flavors

- Too warm (86-95°F/30-35°C): Stressed yeast, potential off-flavors

- Danger zone (above 95°F/35°C): Rapid yeast death begins

- Lethal (above 105°F/40°C): Most yeast cells die quickly

How Distiller’s Yeast Differs from Baker’s and Brewer’s Yeast

Distiller’s yeast has been selectively bred for alcohol tolerance, not temperature resistance. While baker’s yeast prioritizes CO2 production and brewer’s yeast focuses on flavor compounds, distiller’s yeast maximizes alcohol yield. This specialization comes at a cost—most distiller’s yeast strains have temperature sensitivities similar to other Saccharomyces cerevisiae strains, with upper limits around 95-105°F (35-40°C).

Temperature Sensitivity Ranges for Common Distiller’s Yeast Strains

Not all distiller’s yeasts respond identically to temperature changes. Traditional whiskey yeasts typically prefer cooler conditions (65-75°F/18-24°C) than neutral spirits yeasts (75-85°F/24-29°C). Turbo yeasts, engineered for rapid fermentation, generally tolerate slightly higher temperatures but still die around 104-110°F (40-43°C). Heat-tolerant specialized strains like Still Spirits Turbo Heat can function at higher temperatures but sacrifice some efficiency and flavor development in exchange for thermal stability.

Temperature Preferences by Yeast Type:

Traditional Whiskey Yeast: 65-75°F (18-24°C)

Vodka/Neutral Spirits Yeast: 75-85°F (24-29°C)

Rum Yeast: 75-90°F (24-32°C)

Turbo Yeast: 68-90°F (20-32°C)

Heat-Tolerant Yeast: 75-95°F (24-35°C)

What Happens to Yeast Cells When Overheated

At the cellular level, heat damage to yeast is catastrophic. As temperatures climb beyond 95°F (35°C), proteins within yeast cells begin to denature—essentially cooking from the inside. Cell membranes become increasingly permeable, leaking essential components. The yeast’s ability to regulate internal pH deteriorates, and crucial metabolic enzymes stop functioning properly. This cascade of failures quickly leads to cell death if temperatures remain elevated.

The Exact Kill Points for Different Yeast Types

Understanding the precise temperature at which your specific yeast strain dies is crucial for successful fermentation. While general guidelines are helpful, each yeast strain has its own unique thermal death point—the temperature at which cells rapidly die off. Knowing these thresholds can save your batch from disaster during unexpected heat waves or equipment malfunctions. If you’re interested in exploring different moonshine flavors, understanding yeast behavior is essential.

Turbo Yeast Death Temperature (104-110°F/40-43°C)

Turbo yeasts are engineered for speed and efficiency, but they’re surprisingly sensitive to temperature extremes. Despite their rapid fermentation capabilities, most turbo yeasts begin to die rapidly between 104-110°F (40-43°C). The faster metabolism of turbo yeast actually generates more heat during fermentation, creating a dangerous feedback loop if ambient temperatures are already high. This self-heating effect means that turbo fermentations can actually kill themselves if not properly monitored and cooled.

I’ve seen countless batches ruined when distillers assume turbo yeasts can handle higher temperatures due to their robust reputation. In reality, their accelerated metabolism makes temperature control even more critical than with traditional yeasts. Always aim to keep turbo fermentations at least 10°F (6°C) below their kill point to maintain optimal performance.

Traditional Distiller’s Yeast Kill Point (95-105°F/35-40°C)

Classic distiller’s yeasts used for whiskey, rum, and neutral spirits typically have thermal death points between 95-105°F (35-40°C). These yeasts have been selected for generations to produce specific flavor profiles and alcohol yields, not necessarily for temperature tolerance. Their relatively narrow temperature band for optimal performance means they require more careful monitoring than specialized heat-resistant strains.

The tradeoff is worth it—traditional strains often produce superior flavors when kept in their ideal range. In my experience, whiskey yeasts particularly benefit from strict temperature control on the lower end (68-75°F/20-24°C), producing more complex congeners that carry through to the final spirit even after distillation. For more details on how temperature affects the process, you can refer to this guide to fermentation temperature.

Heat-Tolerant Yeast Varieties and Their Limits

For distillers in warmer climates, heat-tolerant yeast strains like Still Spirits Turbo Heat offer a valuable alternative. These specialized yeasts can function at temperatures up to 95-97°F (35-36°C) without significant performance loss, and their thermal death point may extend to 113°F (45°C) in some cases. However, even these hardy strains have their limits—sustained temperatures above 100°F (38°C) will stress them and affect both yield and flavor profile.

It’s worth noting that heat tolerance comes with tradeoffs. These yeasts often produce fewer congeners and may have slightly lower alcohol yields than their temperature-sensitive counterparts when operating at the same temperatures. They’re best viewed as a practical solution for challenging environments rather than an optimal choice for all situations.

How Quickly Yeast Dies at Different Temperature Thresholds

Yeast death isn’t instantaneous at threshold temperatures—it follows a predictable curve that accelerates as temperatures rise. At temperatures just at the kill point, death may take hours as the population gradually declines. As temperatures climb 5-10°F (3-6°C) above the threshold, death can occur within minutes, making quick intervention essential to save a batch.

Brief temperature spikes may not completely destroy your yeast population. If temperatures exceed the kill point for only 15-30 minutes before returning to safe levels, you might lose 30-50% of your viable yeast cells. The surviving cells can often recover and complete fermentation, albeit more slowly. However, extended exposure beyond an hour at kill-point temperatures typically results in complete fermentation failure.

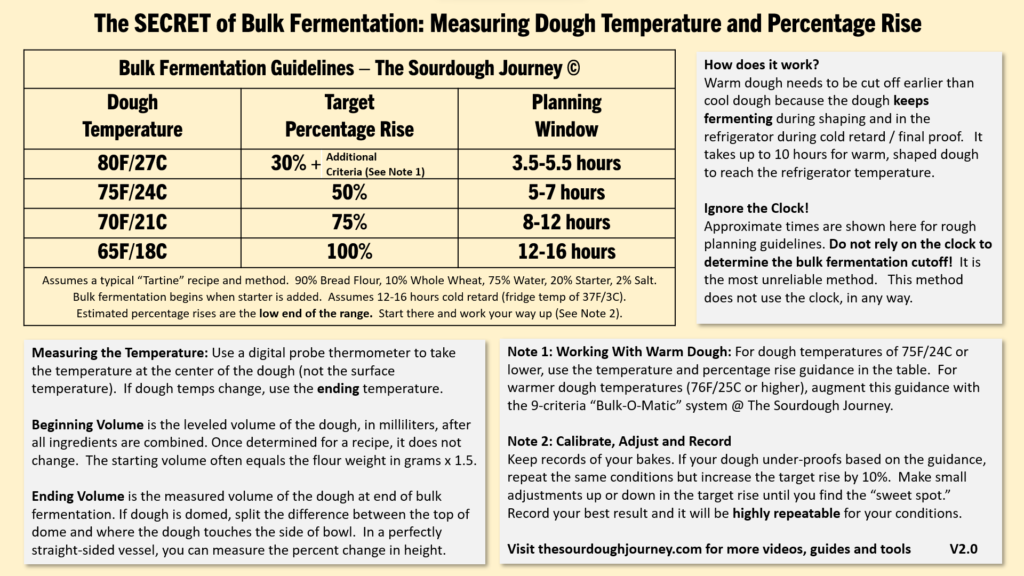

Perfect Temperature Ranges for Fermentation Success

“FAQ – Bulk Fermentation Timing | The …” from thesourdoughjourney.com and used with no modifications.

Successful distillation begins with optimal fermentation temperatures. Finding the sweet spot for your specific yeast strain and desired spirit style requires balancing alcohol production against flavor development. Temperature management isn’t just about keeping yeast alive—it’s about creating the perfect conditions for them to produce the compounds that will define your final product. For a historical perspective on this craft, explore the fascinating history of moonshine.

Ideal Temperature for Maximum Alcohol Yield (75-85°F/24-29°C)

If your primary goal is maximizing alcohol content, the optimal temperature range for most distiller’s yeasts falls between 75-85°F (24-29°C). Within this range, yeast metabolism focuses on efficient sugar conversion with minimal production of secondary compounds. The upper portion of this range (80-85°F/27-29°C) typically produces the fastest fermentation but may sacrifice some flavor complexity.

For neutral spirits where purity is paramount, staying within this range is ideal. I’ve found that maintaining a consistent 78°F (25.5°C) hits the perfect balance between fermentation speed and stress-free yeast activity for vodka base production. Remember that fermentation generates heat, so your ambient temperature should be 5-7°F (3-4°C) lower than your target fermentation temperature.

Temperature Range for Flavor Development (65-75°F/18-24°C)

For spirits where flavor complexity matters—particularly whiskeys, rums, and fruit brandies—cooler fermentations between 65-75°F (18-24°C) often produce superior results. At these lower temperatures, yeast metabolism slows down but produces a wider array of esters, phenols, and other flavor compounds that contribute to a richer final product. The tradeoff is longer fermentation times, often 2-3 days longer than warmer fermentations.

I’ve conducted side-by-side comparisons of corn mash fermentations at different temperatures, and the flavor difference is remarkable. Batches fermented at 68°F (20°C) consistently produced more complex spirits with notes of stone fruit and vanilla that were absent in warmer fermentations of the same mash. These flavor precursors survive distillation and contribute significantly to the character of the final product.

Cold Temperature Effects and Fermentation Stalling

While high temperatures kill yeast quickly, cold temperatures simply put them to sleep. Most distiller’s yeasts become dormant below 60°F (15°C), causing fermentation to slow dramatically or stop entirely. The good news is that cold-stalled fermentations can typically be revived by gradually warming them back to optimal ranges without lasting damage to the yeast or flavor profile.

Cold stalls pose different risks than heat damage. Extended periods at low temperatures increase the chance of competing organisms like bacteria gaining a foothold in your wash. These unwanted microbes can produce off-flavors and acids that survive distillation. If a fermentation stalls due to cold, it’s best to warm it gradually (no more than 5°F/3°C per hour) to avoid shocking the yeast.

- Below 55°F (13°C): Most yeast becomes completely dormant

- 55-60°F (13-15°C): Very slow, potentially incomplete fermentation

- 60-65°F (15-18°C): Slow fermentation with enhanced flavor development

- 65-75°F (18-24°C): Moderate fermentation with balanced flavor production

- 75-85°F (24-29°C): Rapid fermentation with maximum alcohol efficiency

Temperature Control Methods for Home Distillers

“Alcohol Distiller Home Brew Kit …” from www.amazon.com and used with no modifications.

Controlling fermentation temperature doesn’t require expensive equipment. With some creativity and basic materials, you can maintain optimal conditions year-round. The key is understanding that prevention is easier than correction—it takes far less effort to keep temperatures stable than to rescue an overheated fermentation.

Remember that fermentation itself generates heat. A vigorous fermentation can raise the internal temperature of your wash 5-10°F (3-6°C) above ambient room temperature. This means your environmental controls need to account for this self-heating effect, especially during the first 2-3 days when fermentation is most active. If you’re interested in learning more about how to manage this process effectively, check out our guide on aging moonshine.

Cooling Solutions for Hot Environments

1. Immersion Chillers

For precise temperature control, nothing beats an immersion chiller. These copper or stainless steel coils circulate cold water through your fermenting wash without contamination risk. I’ve built simple versions using 25 feet of copper tubing connected to a garden hose that can drop fermentation temperatures by 15°F in under 30 minutes. For maximum efficiency, coil the tubing into a spiral that covers most of the fermenter’s height to ensure even cooling throughout the wash. For those interested in expanding their distilling knowledge, learn about when to stop distilling for optimal results.

2. Wet T-Shirt Method

This evaporative cooling technique is surprisingly effective and costs almost nothing. Simply wrap a cotton t-shirt around your fermenter, secure it with string or rubber bands, then keep it constantly moist by sitting in a shallow pan of water or using a slow drip system. As water evaporates from the shirt, it draws heat from the fermenter. In dry climates, this method can maintain temperatures 10-15°F (6-8°C) below ambient, though it’s less effective in humid environments. Adding a small fan to increase airflow dramatically improves cooling efficiency.

3. Frozen Bottle Rotation Technique

For batch cooling, frozen water bottles provide targeted temperature control. Fill several plastic bottles with water, freeze them solid, then place them directly into your fermentation (if using a bucket) or against the sides of your vessel. Rotate bottles every few hours as they thaw. This method works well for occasional temperature spikes but requires constant attention. To prevent contamination, sanitize the bottles thoroughly before each use and avoid opening your fermenter more than necessary when exchanging bottles.

4. Fermentation Chambers

A dedicated fermentation chamber gives you precise control in any climate. The simplest version is a modified refrigerator or freezer with an external temperature controller. More elaborate setups might include heating elements for cold weather. While this represents a larger investment, the consistency and control it provides pays dividends in product quality. I’ve used a basic chest freezer with a $35 temperature controller for years, maintaining temperatures within 1°F of my target regardless of season.

Heating Options for Cold Weather Distilling

1. Heat Belts and Pads

When ambient temperatures fall below your yeast’s comfort zone, heat belts or brew pads provide gentle, consistent warming. These specialized heating elements wrap around or sit beneath your fermenter, raising temperatures 5-15°F (3-8°C) above ambient. For safety and performance, always use heating elements designed specifically for brewing—never improvise with household heating pads, which can create dangerous hot spots. Pair these devices with a temperature controller for precise regulation.

2. Insulated Fermenters

Insulation helps maintain stable temperatures regardless of ambient conditions. Neoprene fermenter jackets, sleeping bags, or bubble wrap all provide effective insulation at minimal cost. In cool environments, insulation alone often suffices thanks to the heat generated by active fermentation. I’ve achieved excellent results wrapping fermenters in reflective automobile windshield covers, which provide surprising insulation for their low cost and can be secured with bungee cords. If you’re interested in learning about different types of alcohol, check out the six types of alcohol.

3. Water Bath Methods

Water’s high thermal mass makes it an excellent temperature buffer. Placing your fermenter in a larger container of water creates a stable environment that resists temperature swings. In cold conditions, an aquarium heater in the water bath provides precise control. For best results, ensure the water level reaches at least 75% of your fermenter’s height and consider covering the bath with a floating layer of ping pong balls or plastic wrap to minimize evaporation. Learn more about creating a stable fermentation environment with this guide to aging moonshine.

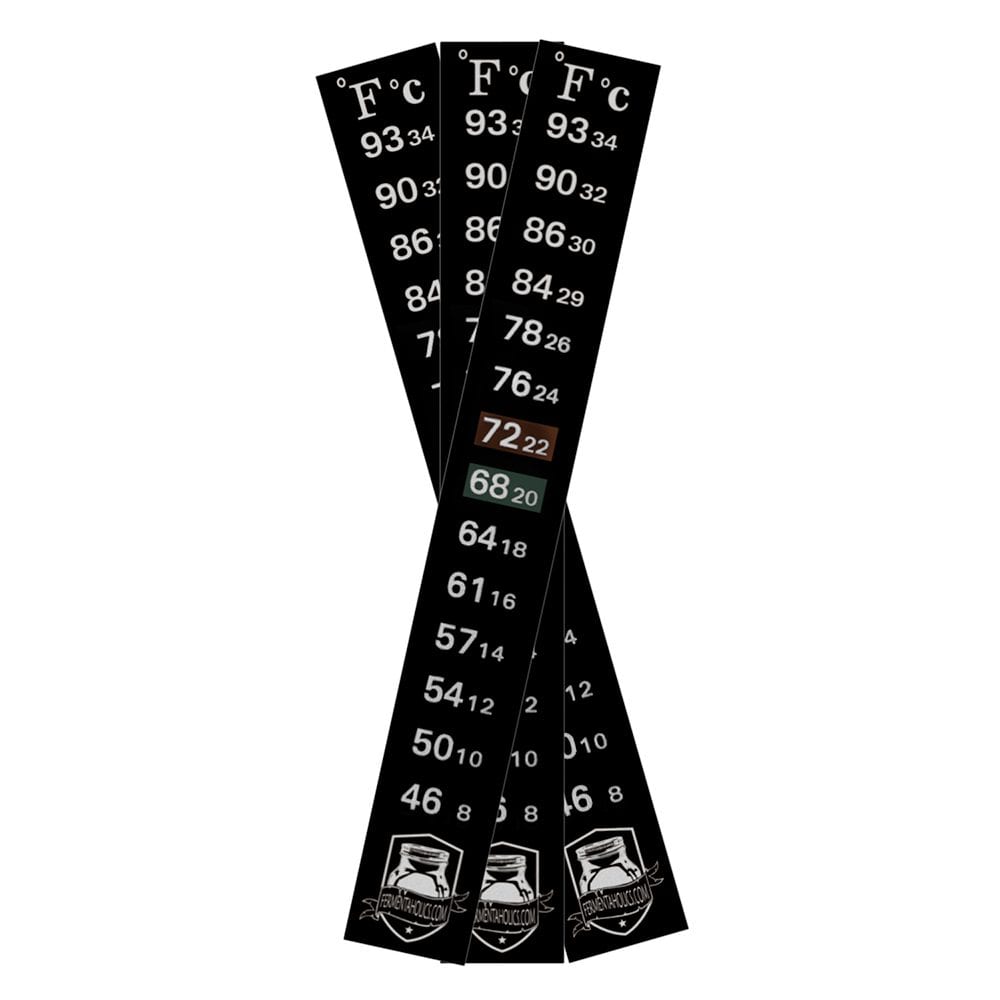

Measuring Fermentation Temperature Accurately

“Adhesive Temperature Strip …” from fermentaholics.com and used with no modifications.

Temperature measurement location matters tremendously. The temperature at the center of your fermenter often differs from the sides by 3-5°F (2-3°C) during active fermentation. For accurate readings, measure the liquid itself rather than relying on ambient air temperature or fermenter surface readings.

Stick-On Thermometer Strips

These inexpensive color-changing strips adhere to the outside of your fermenter, providing a basic temperature indication. While convenient, they measure the fermenter wall temperature rather than the liquid inside, often reading 3-5°F lower than actual wash temperature during active fermentation. They’re useful for trend monitoring but shouldn’t be your only measurement method if precision is important. For a deeper understanding of fermentation, explore the different types of alcohol involved in the process.

Digital Probe Thermometers

For accurate readings without opening your fermenter, infrared thermometers provide instant surface temperature measurements. However, they only measure surface temperature, which can differ significantly from internal temperatures. For more precise measurements, waterproof digital probe thermometers can be sanitized and inserted directly into your wash through a small opening or during gravity readings. Remember to sanitize thoroughly before each insertion to prevent contamination.

Thermowell Installation

For serious distillers, installing a thermowell allows continuous, accurate temperature monitoring without opening your fermenter. This sealed metal tube extends into your wash, allowing a temperature probe to measure internal temperatures without contacting the liquid. Commercial models are available, but DIY versions can be constructed from stainless steel or copper tubing with food-grade silicone sealant. The investment pays dividends in accuracy and convenience, especially for large or expensive fermentations.

Troubleshooting Temperature-Related Fermentation Problems

“Diagnostic Key Fermentation Too Slow …” from wineserver.ucdavis.edu and used with no modifications.

Signs Your Wash Is Too Hot

Catching temperature problems early can save your fermentation. Warning signs of excessive heat include unusually vigorous bubbling followed by a sudden slowdown, strong sulfur odors (rotten egg smell), or a harsh alcohol aroma. Visible signs might include excessive foam formation, condensation on fermenter walls, or wash temperatures more than 10°F (6°C) above ambient temperature. These symptoms typically appear within the first 48 hours of fermentation when yeast activity and heat production peak.

If your specific gravity readings stop decreasing while fermentation is still active, heat stress could be the culprit. Heat-stressed yeast often struggles to complete fermentation, leaving residual sugars and reducing alcohol yield. In extreme cases, the wash may develop a “cooked” aroma similar to canned vegetables or stewed fruit—a clear sign that temperatures have damaged both yeast and flavor compounds.

How to Save an Overheated Fermentation

When temperatures spike dangerously, immediate action can save your batch. First, move the fermenter to the coolest available location and apply cooling methods like ice baths or wet towels. For severe overheating, gently stir the wash to release excess heat, but be careful not to introduce oxygen, which can cause additional problems. Once temperatures return to safe ranges, adding a fresh yeast starter (about 10% the size of your original pitch) can reinvigorate partially damaged fermentations without starting over completely.

Dealing with Temperature Fluctuations

Daily temperature swings can stress yeast even if extremes aren’t reached. Aim to maintain temperatures within a 5°F (3°C) range throughout fermentation. Temperature stability matters more as fermentation progresses—mature yeast cultures become more sensitive to sudden changes. If your environment has unavoidable temperature cycles (like day/night fluctuations), insulation becomes your most important tool. A water bath of sufficient size can absorb daily temperature changes, providing a stable environment despite ambient fluctuations.

Choosing the Right Yeast for Your Climate

“Bourbon, Whiskey, Vodka and Moonshine …” from www.clawhammersupply.com and used with no modifications.

Selecting the appropriate yeast strain for your specific environment can simplify temperature management considerably. Different yeast strains have evolved for different climates, and leveraging these natural adaptations makes fermentation control much easier. The right strain can mean the difference between fighting against nature and working with it.

When evaluating yeast options, consider not just the optimal temperature range but also the strain’s temperature tolerance bandwidth—some yeasts perform well across a 15°F range while others require conditions within a narrow 5°F window. Broader temperature tolerance often correlates with increased fermentation resilience against other stressors like pH fluctuations or nutrient limitations.

Heat-Tolerant Yeast Options for Warm Regions

- Still Spirits Turbo Heat – Functions well up to 95°F (35°C), ideal for tropical climates

- Lallemand DistilaMax HT – Engineered for high-temperature stability up to 98°F (37°C)

- Fermentis SafSpirit HG-1 – Rum and tequila yeast with excellent heat tolerance to 90°F (32°C)

- White Labs WLP099 Super High Gravity – Though designed for high-alcohol fermentations, also shows excellent heat resistance

In consistently warm environments, these specialized strains can produce clean fermentations without elaborate cooling setups. Their temperature tolerance comes with trade-offs, however—most heat-resistant strains produce fewer congeners and aromatic compounds. For neutral spirits, this limitation rarely matters, but it can affect the complexity of whiskeys and rums.

I’ve had excellent results using DistilaMax HT for summer fermentations when controlling temperature below 85°F (29°C) becomes impractical. While the resulting spirits lack some of the subtle ester notes found in cooler fermentations, they avoid the harsh fusel alcohols typically produced when standard yeasts overheat. For neutral spirit production, this clean fermentation profile can actually be advantageous, requiring less filtering and carbon treatment.

Most heat-tolerant yeasts benefit from slightly modified nutrient protocols. Because of their accelerated metabolism at elevated temperatures, staggered nutrient additions often produce better results than adding all nutrients at pitch time. This prevents both nutrient depletion during peak activity and excessive nitrogen in later fermentation stages.

Cold-Tolerant Strains for Cooler Environments

Cold environments present different challenges but can actually produce exceptional flavor complexity when matched with appropriate yeast strains. Traditional distilling yeasts often struggle below 65°F (18°C), but several specialized strains remain active at much lower temperatures, some fermenting effectively down to 55°F (13°C).

- Fermentis SafSpirit M-1 – Malt whiskey yeast with excellent performance down to 59°F (15°C)

- White Labs WLP570 – Belgian Golden Ale yeast that creates complex esters at cool temperatures

- Lallemand DistilaMax MW – Malt whisky yeast with good cold tolerance and exceptional flavor development

- Wyeast 2035 American Lager – Though designed for beer, produces clean fermentations at temperatures as low as 55°F (13°C)

These cold-tolerant strains typically produce more complex flavor compounds than their heat-tolerant counterparts. The slower metabolism at lower temperatures allows for the development of delicate esters and phenols that contribute significantly to spirit character, particularly in whiskey production. The trade-off is extended fermentation times, often 10-14 days instead of the typical 5-7 days at warmer temperatures.

When using cold-tolerant yeasts, temperature stability becomes even more critical. These strains adapt to cold conditions but can struggle with temperature fluctuations, particularly sudden warming. If using these yeasts, aim for rock-steady temperatures rather than attempting to push the lower limits of their range. For more information, you can refer to this guide to fermentation.

All-Purpose Yeasts with Broader Temperature Ranges

For distillers facing variable conditions or those new to temperature management, versatile yeast strains with broader temperature tolerance provide valuable flexibility. These workhorses perform adequately across wider temperature bands, sacrificing some optimization for reliability. They won’t produce the most distinctive character or the fastest fermentations, but they’ll complete the job across a range of conditions. For those interested in exploring different flavors, consider trying moonshine flavors that can complement the yeast’s performance.

Standard distiller’s yeasts like Fermentis SafSpirit Grain and Lallemand DistilaMax LS operate effectively between 65-85°F (18-29°C). This 20°F range accommodates most environments with minimal intervention. For truly variable conditions, brewer’s yeasts like SafAle US-05 offer even broader temperature tolerance (55-90°F/13-32°C) while still producing acceptable spirit bases. These forgiving strains provide an excellent starting point for developing your temperature management skills before moving to more specialized yeasts with narrower optimal ranges. For more insights on managing fermentation conditions, check out this guide to fermentation temperature.

Master Your Fermentation Environment for Better Spirits

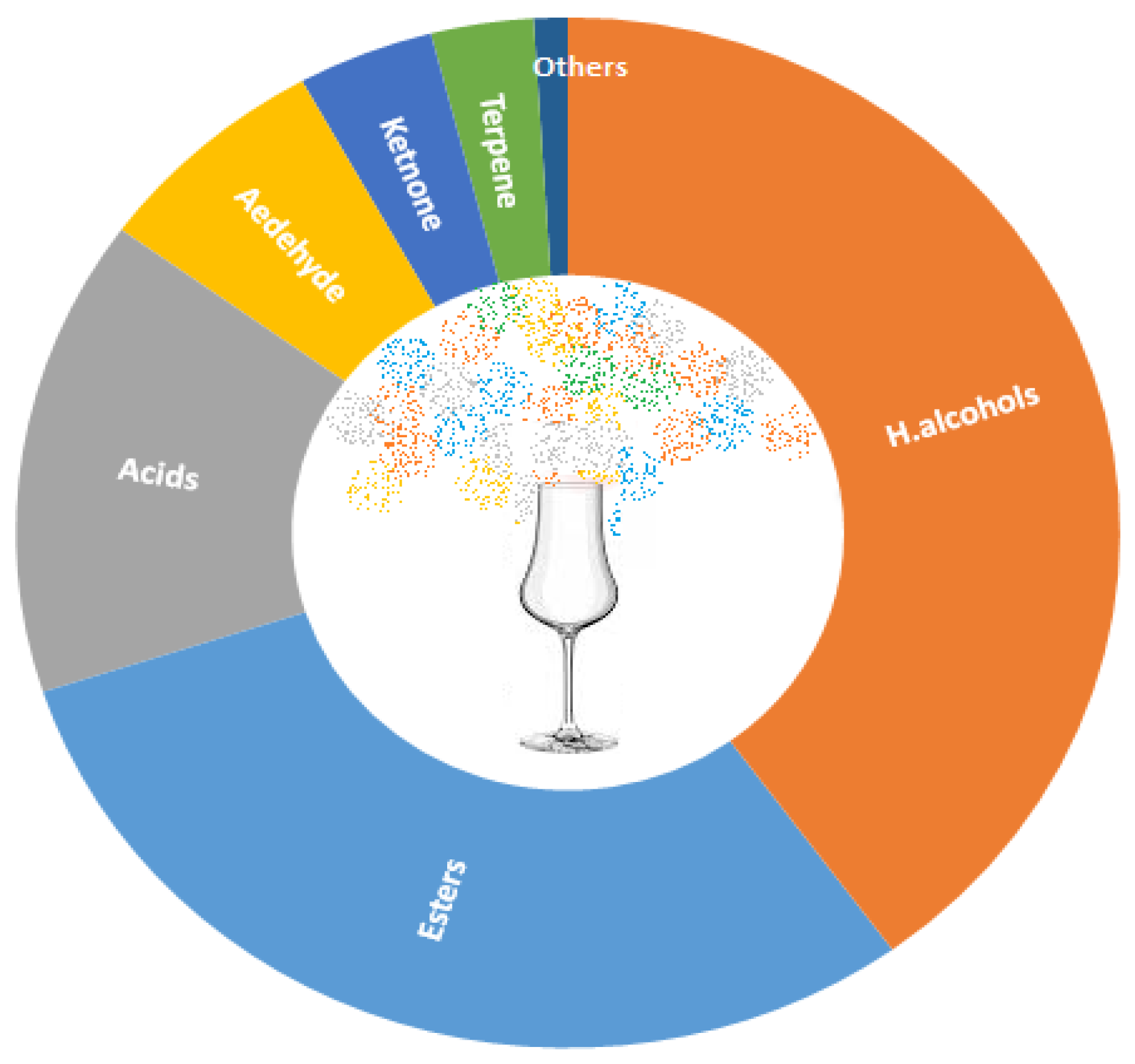

“Alcoholic Fermentation as a Source of …” from www.mdpi.com and used with no modifications.

Temperature control represents one of the highest-impact skills in distilling. Master this variable, and you’ll consistently produce superior wash regardless of equipment limitations or ingredient variables. The best distillers treat temperature as their primary fermentation focus, understanding that proper thermal management eliminates most common problems before they begin. Whether you’re distilling whiskey in winter or vodka in summer, the principles remain the same—know your yeast’s requirements, measure accurately, control proactively, and adjust your approach to match your environment. Still Spirits offers comprehensive temperature management solutions for distillers of all levels, helping you achieve professional-quality results even in challenging conditions.

Frequently Asked Questions

Can I restart fermentation after yeast has been killed by high temperature?

If your yeast has been completely killed by excessive heat (sustained temperatures above 105°F/40°C), restarting fermentation requires pitching fresh yeast. First, cool the wash to proper pitching temperature (below 85°F/29°C), then add new yeast at 1.5-2 times the normal rate to overcome any inhibitory compounds produced during the temperature stress. Adding a small amount of fresh nutrients (about half the normal rate) can help the new yeast establish itself. Be aware that heat-damaged washes often develop flavor issues that may carry through to the final spirit, particularly for whiskeys and rums.

Will a brief temperature spike always kill my yeast completely?

Short temperature excursions above the kill point rarely result in complete yeast death. Most fermentations can recover from brief spikes (15-30 minutes) that exceed optimal ranges by 5-10°F, though fermentation may slow temporarily as the yeast population adjusts. The liquid in your fermenter has significant thermal mass, meaning internal temperatures change more slowly than ambient air. This provides some protection against brief environmental temperature fluctuations. However, repeated temperature spikes cause cumulative stress damage, weakening yeast with each cycle and potentially leading to stuck fermentations.

How does temperature affect the flavor profile of my final spirit?

Temperature dramatically influences the congener profile of your wash, which carries through distillation to affect final spirit character. Lower fermentation temperatures (65-70°F/18-21°C) generally produce more esters (fruity, floral notes) and fewer fusel alcohols (harsh, solvent-like notes). Higher temperatures (80-85°F/27-29°C) typically produce more phenolic compounds and higher alcohols that can contribute both desirable complexity and undesirable harshness depending on concentration.

The temperature impact varies by spirit type. Whiskeys benefit substantially from cooler, slower fermentations that develop complex esters and fruity notes. Rums traditionally employ warmer fermentations to develop characteristic tropical fruit esters and phenolic compounds. Neutral spirits aim to minimize congener production through careful temperature control in the middle ranges (75-80°F/24-27°C) to balance fermentation speed with clean flavor development.

Should I adjust my fermentation temperature based on the season?

Adapting your approach seasonally makes temperature management much simpler. Rather than fighting extreme conditions, consider adjusting your production schedule to match your environment. Summer months are ideal for neutral spirits and rum production, which tolerate or benefit from warmer fermentations. Reserve whiskey production for cooler months when maintaining lower temperatures requires less intervention.

If seasonal adjustment isn’t practical, consider adjusting your yeast selection instead. Heat-tolerant strains in summer and cold-tolerant strains in winter can expand your functional temperature range significantly. Many distillers maintain a seasonal rotation of 2-3 different yeast strains specifically selected for their environmental conditions, ensuring consistent results year-round without excessive temperature control investment.

Can I use a sous vide device to maintain precise fermentation temperatures?

Sous vide immersion circulators offer exceptional temperature control for small-batch fermentations. These devices can maintain temperatures within 0.1°F of your target, eliminating temperature fluctuations entirely. To implement this system, place your fermenter in a water bath large enough to accommodate both the fermenter and the circulator. The circulator will heat and circulate the water to maintain perfect temperature consistency.

This method works best for heating rather than cooling—most circulators can heat water but not chill it. For cooling needs, you can add sealed ice packs to the water bath while the circulator maintains your target temperature. The main limitations are batch size and cost—most home circulators handle water baths up to 5-7 gallons effectively, suitable for 3-5 gallon fermentations. For larger batches, dedicated brewing temperature controllers paired with heating elements or cooling systems provide more cost-effective solutions.

When using sous vide for fermentation control, position the circulator away from the fermenter to avoid hot spots, and ensure the water level remains above the circulator’s minimum line as evaporation occurs. Many distillers report that sous vide temperature control produces exceptionally clean fermentations with minimal off-flavors, particularly for neutral spirits and light whiskeys where subtle temperature fluctuations can significantly impact flavor development.