What Are the Three Main Parts of a Still: Simple Guide to Distilling Equipment

Article-At-A-Glance

- A distillation still consists of three primary components: the boiler (pot), the column/neck, and the condenser, each playing a crucial role in transforming fermented wash into spirits

- The boiler heats the fermented liquid to create alcohol vapor, with copper and stainless steel being the most common materials used due to their unique properties

- Column design significantly impacts the final spirit’s flavor profile and ABV, with reflux columns producing higher proof, cleaner spirits than simple pot still designs

- The condenser transforms alcohol vapor back into liquid form through cooling processes, with worm coils and shell-and-tube designs being the most prevalent types

- Understanding the interaction between these three components allows distillers to control the character and quality of their final product

Understanding the main parts of a still isn’t just for moonshiners hiding in the hills. Whether you’re a curious enthusiast or considering craft distilling, knowing how these remarkable devices work provides essential context for appreciating spirits of all types. At its core, a still operates on a beautifully simple principle: separating alcohol from water through controlled heating and cooling.

Every functional still, from the most rustic hillbilly rig to sophisticated commercial systems, contains three fundamental components that work together to transform fermented liquid into concentrated spirits. These three main parts—the boiler, column/neck, and condenser—each serve distinct but interconnected purposes in the distillation process. Clawhammer Supply experts note that mastering how these components work together is the first step to successful distillation.

Let’s break down these essential elements one by one, exploring how each contributes to the art and science of creating distilled spirits. By understanding these fundamentals, you’ll gain insight into why different spirits have distinctive characteristics and how distillers manipulate their equipment to achieve specific results.

The Essential Components of a Distillation Still

“Home Moonshine Still Distiller Pure …” from www.amazon.com and used with no modifications.

The journey from fermented wash to finished spirit requires three crucial still components working in harmony. The boiler (sometimes called the pot or kettle) provides the heat source that vaporizes alcohol. The column or neck creates the pathway for vapor to travel and potentially undergo further refinement. Finally, the condenser transforms the purified alcohol vapor back into liquid form.

While additional components like thermometers, collection vessels, and various attachments might supplement these main parts, they’re ancillary to the core trio. These three elements represent the minimum viable configuration for a functional still. Historically, even the simplest alembic stills developed centuries ago featured these same basic components, demonstrating how fundamental they are to the distillation process.

What Makes a Still Work

At its heart, distillation exploits differences in boiling points between water (212°F/100°C) and ethanol (173.1°F/78.37°C). By carefully controlling temperature, a still allows alcohol to vaporize before water, creating alcohol-rich vapor that’s eventually condensed back into liquid form. This principle explains why proper temperature control remains critical throughout the distillation process.

The actual mechanics involve heating fermented liquid in the boiler until alcohol begins to evaporate. This vapor rises through the column or neck, where depending on design, it may undergo additional purification. Finally, it reaches the condenser where cooling transforms it back to liquid—now with significantly higher alcohol content than the original fermented wash.

The Boiler: Where Heat Transforms Liquid

“Moonshine Stills 13 Gallon Still Boiler …” from www.amazon.com and used with no modifications.

The boiler (or pot) serves as both container and heating vessel for your fermented wash. This is where the magic begins—where heat energy transforms liquid into vapor, initiating separation of alcohol from water and other compounds. Think of it as the foundation of the entire system, providing the energy needed to drive the distillation process.

Size matters significantly with boilers. Commercial operations might employ massive vessels holding hundreds or thousands of gallons, while hobby distillers typically work with 5-15 gallon capacities. Regardless of size, boilers must safely contain liquid while providing even, controlled heat distribution. Most importantly, they must withstand repeated heating cycles without degrading or contaminating the spirit.

Functions and Features of the Boiler

Beyond simply holding and heating liquid, well-designed boilers include several important features. Many incorporate thermometers or temperature probes to monitor internal conditions precisely. Others feature sight glasses or level indicators to track liquid volume during operation. Proper insulation can significantly improve energy efficiency and temperature stability, especially important for maintaining precise control during critical separation phases.

Common Boiler Materials

The two predominant materials used for still boilers are copper and stainless steel, each offering distinct advantages. Copper has been the traditional choice for centuries due to its excellent heat conductivity and its remarkable ability to bind with sulfur compounds that would otherwise create unpleasant flavors. This catalytic reaction helps produce cleaner, smoother spirits—especially crucial for whiskeys and brandies. However, copper requires more maintenance and is generally more expensive.

Stainless steel, the modern alternative, provides superior durability and easier cleaning. It’s non-reactive, resistant to corrosion, and typically less expensive than copper. Many commercial distilleries use stainless steel boilers with copper components strategically placed in the vapor path to achieve a balance of durability and flavor benefits. The choice between these materials depends on your budget, maintenance preferences, and the specific flavor profile you’re seeking.

How Boiler Shape Affects Your Distillate

Boiler geometry significantly influences distillation dynamics in ways that directly impact your final spirit. Tall, narrow boilers promote reflux (vapor recondensing and falling back into the boiler), leading to greater purification and higher alcohol content. Conversely, wide, shallow boilers allow more flavor compounds to rise with alcohol vapor, creating more robust, character-rich spirits like whiskey and rum.

The angle of the boiler’s shoulder where it connects to the column or lyne arm also matters. Steeper angles reduce reflux and carry more flavor compounds into the distillate. This explains why pot stills designed for flavorful spirits often feature distinctive “onion” or “lamp” shapes with rounded shoulders that minimize reflux. Understanding these design elements helps explain why different still shapes produce such distinctive spirit profiles.

The Column/Neck: Creating Vapor Pathways

“2 inch Moonshine Still Column Type-A …” from www.amazon.com and used with no modifications.

Rising from the boiler, the column (sometimes called the neck, lyne arm, or swan neck) serves as the pathway for alcohol vapor to travel toward the condenser. This component varies dramatically between still designs, ranging from the simple swan neck of a pot still to the complex multiple-plate columns found in commercial distilleries. The column’s design fundamentally determines the level of rectification (purification) that occurs during distillation.

In its most basic form, the column simply channels vapor toward the condenser. More complex columns, however, create opportunities for reflux and multiple vaporization/condensation cycles, leading to higher-proof, cleaner spirits. The column represents perhaps the most diverse part of still design, with countless variations developed over centuries of distilling innovation.

Simple vs. Reflux Columns

Simple columns, typical of traditional pot stills, offer minimal rectification. They primarily transport vapor from boiler to condenser with limited opportunity for reflux or additional purification. This design preserves more congeners (flavor compounds), making them ideal for spirits where character matters—think whiskey, brandy, and rum. Their simplicity also makes them easier to operate and understand for beginning distillers.

Reflux columns, by contrast, intentionally promote internal condensation and re-vaporization through various design elements. Typically taller and sometimes containing plates, packing materials, or cooling jackets, these columns create multiple theoretical distillation stages within a single run. The result is higher-proof, cleaner spirits with fewer congeners—perfect for vodka, gin bases, and neutral spirits. The trade-off is greater complexity and less distinct flavor character in the final product.

How Height and Design Impact Distillate Purity

Column height directly correlates with distillate purity—taller columns generally produce higher-proof, cleaner spirits. This occurs because alcohol vapor must travel farther, encountering more opportunities for heavier compounds to condense and fall back into the boiler. Each additional inch of column height increases potential for reflux, which explains why commercial vodka stills often feature columns several meters tall. For those curious about how much whiskey a 5-gallon still can produce, understanding column height and design is crucial.

Beyond height, internal design elements like dephlegmators (partial condensers), bubble caps, and various packing materials further enhance rectification. These features increase surface area for vapor-liquid interaction, promoting more complete separation of alcohol from water and congeners. Some advanced column designs even incorporate multiple draw points, allowing distillers to capture different fractions simultaneously from various column sections.

Plates and Packing Materials Explained

Many professional column stills incorporate plates—horizontal barriers with holes that force vapor to bubble through a thin layer of condensed liquid. Each plate essentially creates a mini-distillation, with heavier compounds falling back down while lighter alcohols continue rising. Commercial distilleries might use stills with dozens of plates, each adding theoretical refinement to the final spirit. For those interested in moonshine production, understanding how much liquor 10 gallons of mash can make is crucial for refining the distillation process.

Packing materials offer an alternative to plates, particularly in hobby and craft distilling. Materials like copper mesh, ceramic raschig rings, or stainless steel scrubbers increase surface area within the column, providing condensation points for reflux. The density and type of packing significantly impact distillation characteristics—tighter packing creates more reflux and higher-proof spirits, while looser arrangements allow more flavor compounds through.

The Condenser: Cooling Vapor Into Liquid

“Moonshine Condenser Copper Worm” from vengeancestills.com and used with no modifications.

The condenser completes the distillation process by cooling alcohol vapor back into liquid form. Without this critical component, vapor would simply dissipate into the air rather than becoming collectible spirits. Using controlled temperature reduction, the condenser causes molecules in vapor state to slow down, return to liquid form, and flow into collection vessels as finished distillate. For more on how distillation affects alcohol potency, explore whether moonshine gets more potent with age.

Types of Condensers

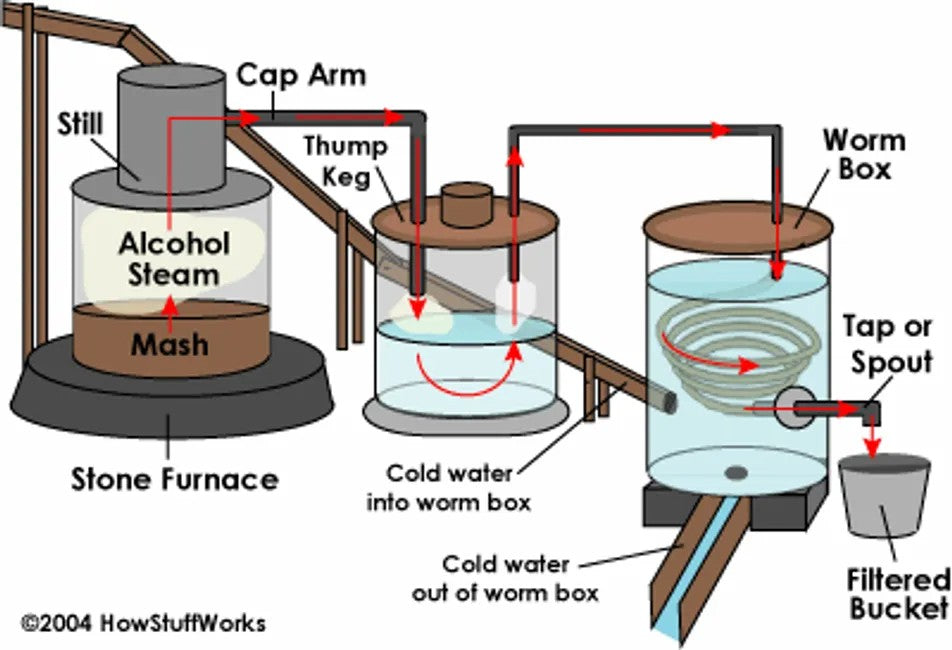

The two most common condenser designs are worm coils and shell-and-tube condensers. Worm coils are the traditional choice—a long copper tube coiled inside a water-filled container. As vapor travels through this spiral tube, it gradually cools and condenses. Worm coils are simple, effective, and add character to spirits by providing additional copper contact. Their gradual cooling process can retain more volatile flavor compounds that might be lost in more efficient designs.

Shell-and-tube condensers represent the modern approach, featuring multiple smaller tubes inside a water jacket. They provide faster, more efficient cooling through increased surface area and are easier to clean than traditional worm coils. Many craft distillers prefer these for their efficiency and cleanliness, especially when producing higher-proof neutral spirits where rapid condensation is advantageous. Their compact design also makes them ideal for space-constrained distilling operations.

Cooling Methods and Efficiency

Water circulation serves as the primary cooling medium in most still condensers. Hobbyists often use simple pumps to circulate cold water around or through condenser components. Commercial operations might employ sophisticated chillers or cooling towers to maintain precise temperatures. The efficiency of your cooling system directly impacts distillation speed and the quality of your final product. For those interested in the specifics of production, you might wonder how much whiskey a 5-gallon still can produce.

Temperature differential between vapor and cooling water determines condensation efficiency. Ideally, cooling water should be at least 20°F cooler than the vapor temperature. Flow rate matters too—insufficient water flow may lead to incomplete condensation, while excessive flow wastes resources. Many experienced distillers monitor distillate output temperature, aiming for collection at room temperature or slightly above to ensure complete condensation without losing volatile aromatics.

Material Considerations for Condensers

Copper remains the gold standard for condensers due to its exceptional heat transfer properties and continued sulfur-scrubbing benefits. Even in stills with stainless steel boilers, copper condensers are often preferred for their ability to remove unwanted compounds during the critical condensation phase. This material choice explains the distinctive bright copper coils seen in traditional distilleries worldwide. For those interested in the distillation process, you might wonder how much liquor 10 gallons of mash make.

Stainless steel condensers offer excellent durability and are particularly suitable for neutral spirits where copper’s catalytic effects are less crucial. Some modern designs use hybrid approaches—stainless steel tubing with copper mesh inserts to combine durability with copper’s beneficial properties. The material choice should align with your target spirit style, maintenance preferences, and budget considerations.

Connecting the Parts: A Complete Still System

“A Complete Guide to Moonshine, Still …” from www.countryfarm-lifestyles.com and used with no modifications.

The effectiveness of a still depends not just on individual components but on how seamlessly they work together. Proper connections between boiler, column, and condenser are critical for both safety and quality. Vapor leaks can reduce efficiency, create potential hazards, and affect spirit quality. Professional setups typically use sanitary tri-clamp fittings that create reliable, leak-proof connections that can be easily disassembled for cleaning.

Proper Seals and Fittings

Historically, flour paste or dough served as emergency seals in traditional distilling. Modern distillers rely on food-grade silicone gaskets, PTFE tape, or specialized high-temperature sealing compounds. Whatever method you choose, all connections must be vapor-tight to prevent alcohol loss and ensure safety. Regular inspection of seals and fittings should be part of your pre-distillation checklist.

Connection types vary by still design and manufacturer. Traditional copper stills often use flanged joints secured with bolts or clamps, while modern systems prefer sanitary tri-clamps that provide reliable seals and quick disassembly. Some hobby stills use threaded connections with PTFE tape—functional but requiring careful installation to prevent leaks. Quality connections might seem like minor details, but they significantly impact both safety and distillate quality.

How the Three Parts Work Together

The distillation process demonstrates perfect synergy between the three main components. Heat applied to the boiler creates alcohol-rich vapor that rises naturally into the column. The column’s design determines how much rectification occurs as vapor travels upward. Finally, the condenser transforms purified vapor back into liquid form—now significantly higher in alcohol than the original wash.

Proper balance between these components is essential. An oversized boiler paired with an undersized condenser creates a bottleneck where vapor production exceeds condensation capacity. Similarly, column design must complement your intended spirit style—a neutral spirit still needs significantly more rectification than one designed for flavorful whiskey. Understanding how these components interact helps distillers optimize their setup for specific spirit types.

Additional Equipment That Enhances Distillation

“20 Gallon Distillers Kit | Distillation …” from vengeancestills.com and used with no modifications.

While the boiler, column, and condenser form the essential trio, several supplementary components can significantly improve your distilling experience. Thermometers or probes at critical points allow precise temperature monitoring. Sight glasses help track liquid levels without opening the system. Collection vessels with parrot spouts enable real-time monitoring of proof during distillation. These additions transform basic distilling into a more controlled, precise process.

Temperature Control Tools

Precision temperature management represents perhaps the most significant advancement in modern distilling. Digital thermometers with tenth-of-a-degree accuracy help identify critical transition points between foreshots, heads, hearts, and tails. Some advanced setups incorporate computer control systems that automatically adjust heat input to maintain target temperatures. Even simple analog thermometers positioned at boiler, column top, and condenser output provide valuable data for making critical distillation decisions.

Collection Vessels and Parrot Spouts

The collection system matters more than many beginners realize. A proper setup includes a spirit-safe or collection vessel that catches the distillate while allowing visual inspection. Parrot spouts (or proofing parrots) direct the distillate through a hydrometer chamber before collection, enabling continuous monitoring of alcohol content. This real-time feedback helps distillers make precise cuts between different fractions.

Collection vessels should be made from non-reactive materials like glass, stainless steel, or food-grade plastic. Many distillers prefer glass for small batches because it allows visual assessment of clarity and doesn’t impact flavor. Larger operations typically use stainless steel for durability and ease of cleaning. Whatever material you choose, ensure it’s thoroughly clean and free from any residues that might affect your distillate.

Safety Features Every Still Should Have

Safety cannot be overstated when working with equipment that combines alcohol vapor and heat sources. Pressure relief valves prevent dangerous pressure buildup in sealed systems. Water management systems for condensers ensure continuous cooling without operator attention. Temperature cut-off switches can automatically reduce heat if temperatures exceed safe parameters. These features protect both the distiller and the equipment from potentially dangerous situations.

Beyond mechanical safety features, proper ventilation remains essential. Alcohol vapor is both flammable and can displace oxygen in confined spaces. Always operate stills in well-ventilated areas away from open flames or spark sources. Many commercial distilleries incorporate explosion-proof electrical systems and specialized ventilation to address these risks. Even small hobby setups should prioritize proper air circulation and fire safety.

Pot Still vs. Column Still: Key Differences

:max_bytes(150000):strip_icc()/LQR_Edit_ColumnVsPotTwitter-1500x785-4e587701d04b49beba99f21d890618cf.jpg)

“Pot and Column Stills …” from www.liquor.com and used with no modifications.

The distinction between pot and column stills represents the most fundamental design division in the distilling world. Pot stills, with their simple boiler-to-condenser configuration, typically produce spirits with more flavor compounds and lower alcohol concentration (usually 60-80% ABV). Their batch operation and limited rectification preserve congeners that create distinctive character in spirits like whiskey, brandy, and traditional rum.

Column stills (also called continuous or reflux stills) incorporate multiple plates or packing to create higher rectification. They can produce much higher alcohol concentrations—often 95% ABV or higher—with fewer flavor compounds. Many column stills operate continuously, processing feed stock and removing distillate without stopping. This efficiency makes them ideal for industrial production, particularly for neutral spirits like vodka or light rum bases. For more information, you can check out this distillation equipment guide.

Quick Comparison: Pot Still vs. Column Still

Pot Still: Batch operation, 60-80% ABV output, more flavor compounds, ideal for whiskey/brandy/rum

Column Still: Continuous operation possible, 90-95%+ ABV output, fewer flavor compounds, ideal for vodka/neutral spirits

Spirit Types and Their Ideal Still Configurations

Different spirits traditionally call for specific still configurations. Whiskey typically relies on pot stills or hybrid pot-column designs that preserve grain character while removing unpleasant fusel oils. Vodka requires extensive rectification from tall column stills to achieve its characteristic neutrality. Rum spans both worlds—from flavor-rich pot still rums to column-distilled light varieties. Gin usually begins with neutral column-distilled spirit that’s then redistilled with botanicals. Understanding these relationships helps explain why spirits from different categories have such distinctive profiles.

When to Choose Each Design

Your choice between pot and column designs should align with your target spirits and production goals. Pot stills excel for flavor-forward craft spirits where character matters more than absolute purity or efficiency. Their simplicity also makes them more approachable for beginners. The batch nature of pot distillation provides greater control over cuts between foreshots, heads, hearts, and tails, allowing precise flavor management.

Column stills make sense when efficiency, higher proof, or neutrality are priorities. Their continuous operation capability makes them attractive for commercial production where consistency and throughput matter. Many craft distillers compromise with hybrid designs—a pot still with a small rectification section or removable plates that allow flexibility between different spirit styles.

Maintaining Your Still for Perfect Results

“MOONSHINE STILL – Hobby Distillers …” from www.thedistillerynetwork.com and used with no modifications.

Proper maintenance ensures both safety and quality in distilling operations. Neglected stills develop problems ranging from off-flavors to potentially dangerous conditions. Regular cleaning, inspection of seals and connections, and proper storage between uses extend equipment life and maintain spirit quality. Develop a consistent maintenance schedule and follow it religiously—especially for copper components that require special attention.

Cleaning Between Runs

Immediately after distilling, rinse your still thoroughly with hot water to remove residual alcohol and prevent buildup of organic materials. Some distillers run a sacrificial batch of water through the entire system, discarding this cleaning run. For tougher residues, a solution of water and citric acid (for copper) or specialized cleaning chemicals designed for distilling equipment may be necessary. Always follow rinses with plain water to remove any cleaning agents before your next spirit run.

Different spirits may require different cleaning approaches. When switching between spirit types (particularly from strongly flavored to neutral products), more aggressive cleaning may be needed. Some distillers dedicate specific equipment to particular spirits to avoid cross-contamination. Always consult manufacturer guidelines for specific cleaning recommendations for your equipment. For further insights on maintaining quality, check out these storage conditions for aged moonshine.

Long-Term Care for Each Component

Copper components require special attention due to their tendency to develop verdigris (the characteristic blue-green patina) when exposed to air and moisture. This copper oxide can impart unpleasant flavors to spirits. Many distillers use a solution of vinegar and salt to clean copper surfaces, followed by thorough rinsing. Commercial copper cleaners formulated for distilling equipment provide another effective option.

Stainless steel components generally require less intensive maintenance but should still be thoroughly cleaned after each use. Check gaskets and seals regularly for signs of deterioration or hardening that might compromise vapor-tight connections. Store your still in a clean, dry environment with boiler and condensers drained to prevent moisture accumulation. For rarely used equipment, consider a deep cleaning before storage and again before next use.

Frequently Asked Questions

Understanding still components leads to many questions from both beginners and experienced distillers. The following answers address some of the most common inquiries about still design, materials, and operation. Remember that distilling equipment continues evolving, with innovations regularly emerging from both commercial manufacturers and creative craft distillers.

What’s the difference between copper and stainless steel stills?

Copper stills offer superior heat conduction and catalytic removal of sulfur compounds, resulting in smoother spirits with fewer off-flavors. They’re traditional for flavor-forward products like whiskey and brandy. However, copper requires more maintenance, develops patina, and costs more than stainless alternatives. Stainless steel stills provide durability, easy cleaning, and lower maintenance, though they lack copper’s catalytic benefits. Many modern stills use hybrid designs—stainless boilers with copper components in vapor paths—to balance these advantages.

Can I build my own still at home?

Building a still requires careful planning, proper materials, and attention to safety details. Many distillers successfully construct small stills from copper pipe, kettles, and condensing coils, while others modify kegs or pressure cookers as boilers. Numerous plans and kits are available for DIY construction. However, remember that homemade equipment demands rigorous safety testing before use. Pay special attention to pressure relief, secure connections, and proper condenser design. Most importantly, check local regulations—while equipment ownership may be legal in many jurisdictions, operating without permits typically isn’t.

Why do some stills have multiple columns?

Multiple columns allow for specialized functions at different stages of distillation. A common configuration uses a primary column for initial separation followed by a secondary rectification column for further purification. This approach provides greater control than a single column of equivalent height. Multiple columns also enable different temperatures in each section, allowing precise management of which compounds rise and which fall back. Some advanced designs incorporate specialized columns for particular purposes—like gin baskets that hold botanicals or thumpers that create additional vapor-liquid interactions.

How does the size of a still affect the distillation process?

Still size impacts more than just production volume. Larger stills generally provide more consistent results because they create more stable temperature gradients and are less affected by minor fluctuations. Smaller stills heat and cool more rapidly, requiring more attentive management but offering greater agility for experimental batches. Surface-to-volume ratio also changes with size—smaller stills have proportionally more copper surface contact with the same volume of spirit, potentially increasing copper interaction. Most distillers find their technique must adjust when scaling between different sized equipment.

Is a thumper keg considered a main part of a still?

While not one of the three essential components, a thumper (or doubler) represents an important addition in many traditional setups. This secondary chamber sits between the pot still and condenser, creating an additional vapor-liquid interaction that increases alcohol concentration without a formal second distillation. Thumpers traditionally allow single-distillation moonshine to achieve higher proof while retaining flavor. They can also hold additional flavoring ingredients like fruit or herbs. Though not universal, thumpers remain common in heritage distilling traditions, particularly in Appalachian and Caribbean rum production.

Understanding the three main components of a still—boiler, column, and condenser—provides the foundation for appreciating the art and science of distillation. Whether you’re a curious enthusiast or planning to enter the craft distilling world, this knowledge helps explain the incredible diversity of spirits available today.

From the distinctive character of pot-distilled whiskeys to the pristine neutrality of column-distilled vodka, every spirit’s profile connects directly to the equipment used in its creation. By mastering these fundamentals, distillers continue refining an ancient craft while developing innovative new expressions.

For more guidance on selecting the right still for your distilling journey or to explore quality distilling equipment for your craft spirits production, Clawhammer Supply offers resources and equipment tailored to both beginners and experienced distillers.

Distilling is an ancient art that involves the separation of alcohol from water and other components in a liquid. The process requires specific equipment, including a still, which is essential for producing high-quality spirits. A still typically consists of three main parts: the pot, the column, and the condenser. Each part plays a crucial role in the distillation process, ensuring that the final product is pure and flavorful. For those interested in learning more about distillation equipment, this distillation equipment guide provides valuable insights and tips.